A production process of technical veneer

A production process and technology of technological veneer, applied in the field of wood processing, can solve the problems of rigid texture of technological veneer, rigid color transition, unnatural stripes, etc., and achieve the effect of strong overall three-dimensional effect of veneer, natural color transition, and natural and changeable flower shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

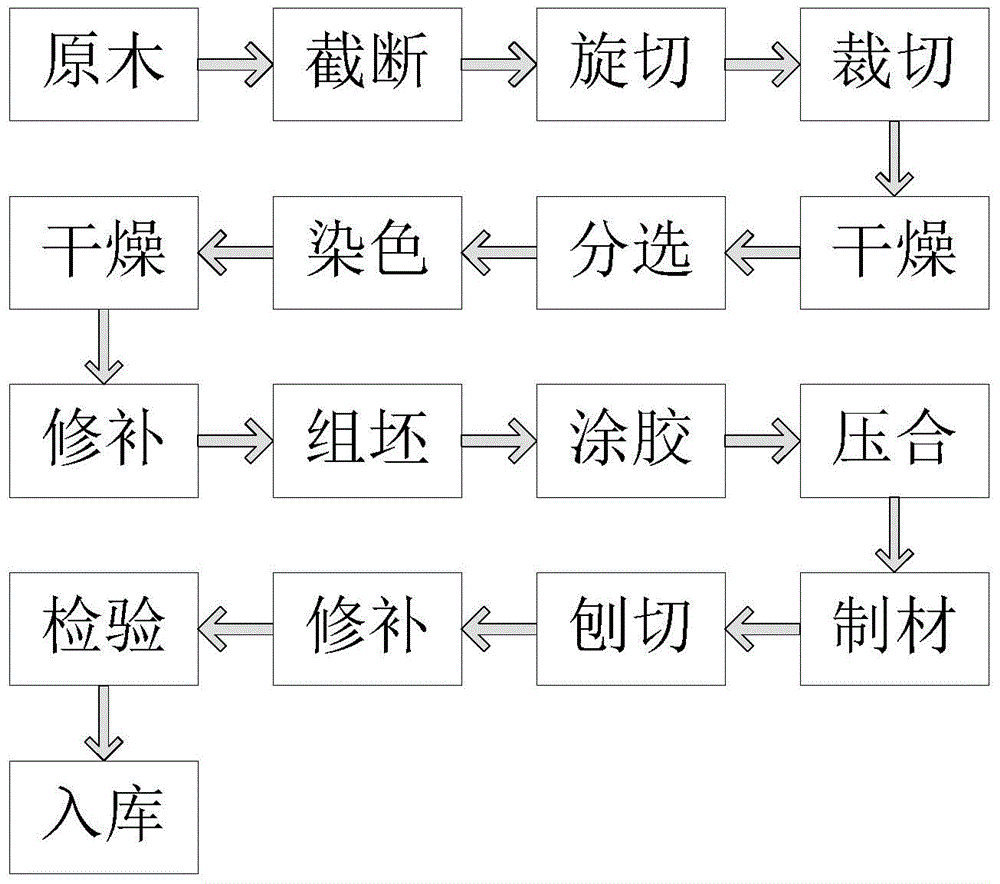

[0040] Embodiment: a kind of production technology of technology veneer, now take the production technology of black walnut tree root technology veneer as example, this technology specifically comprises the following steps:

[0041] (1) Cutting: cut the log into the required size by the cutting machine;

[0042] (2) Rotary cutting: the truncated wood is rounded by a rotary cutting machine, and then cut into veneers of the required size;

[0043] (3) Cutting: the veneer is cut into the required size by an automatic cutting machine;

[0044] (4) drying: drying the cut veneer, and controlling its moisture content at 10-14%;

[0045] (5) Sorting: The veneers after drying are divided into grade A, grade B, grade C, grade D and sub-grade five according to the quality of material color and surface quality;

[0046] (6) Dyeing: Select the veneer of the corresponding grade according to the required material color and texture, and dye the selected veneer. The dyes are proportioned acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com