PCB and direct type backlight module with PCB

A backlight module, direct-type technology, applied in the field of direct-type backlight modules, can solve the problem of uneven lighting and shadow display, and achieve the effect of weakening the lighting phenomenon, simple solution, and improving optical taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

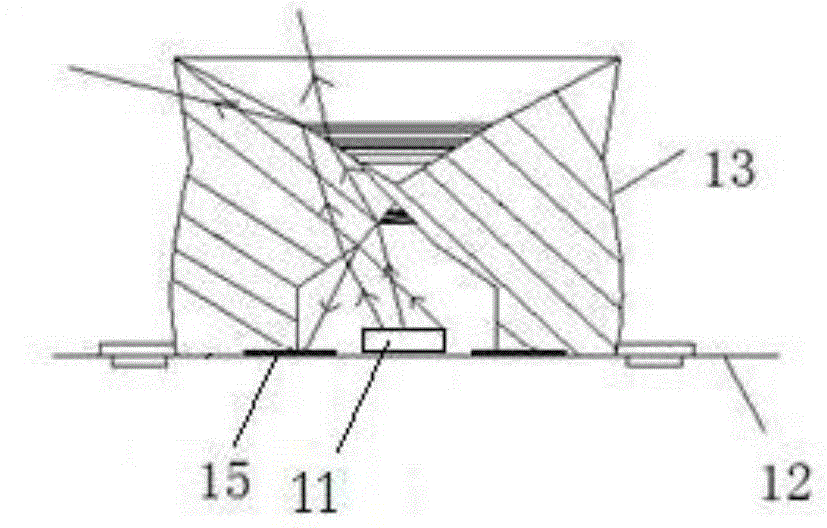

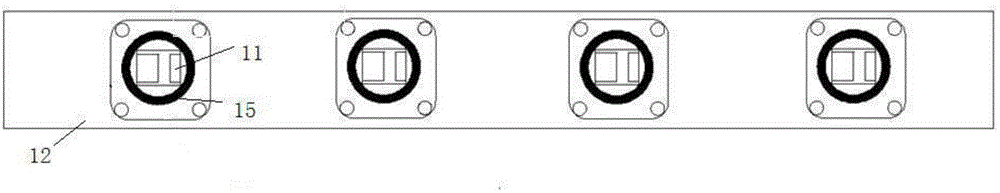

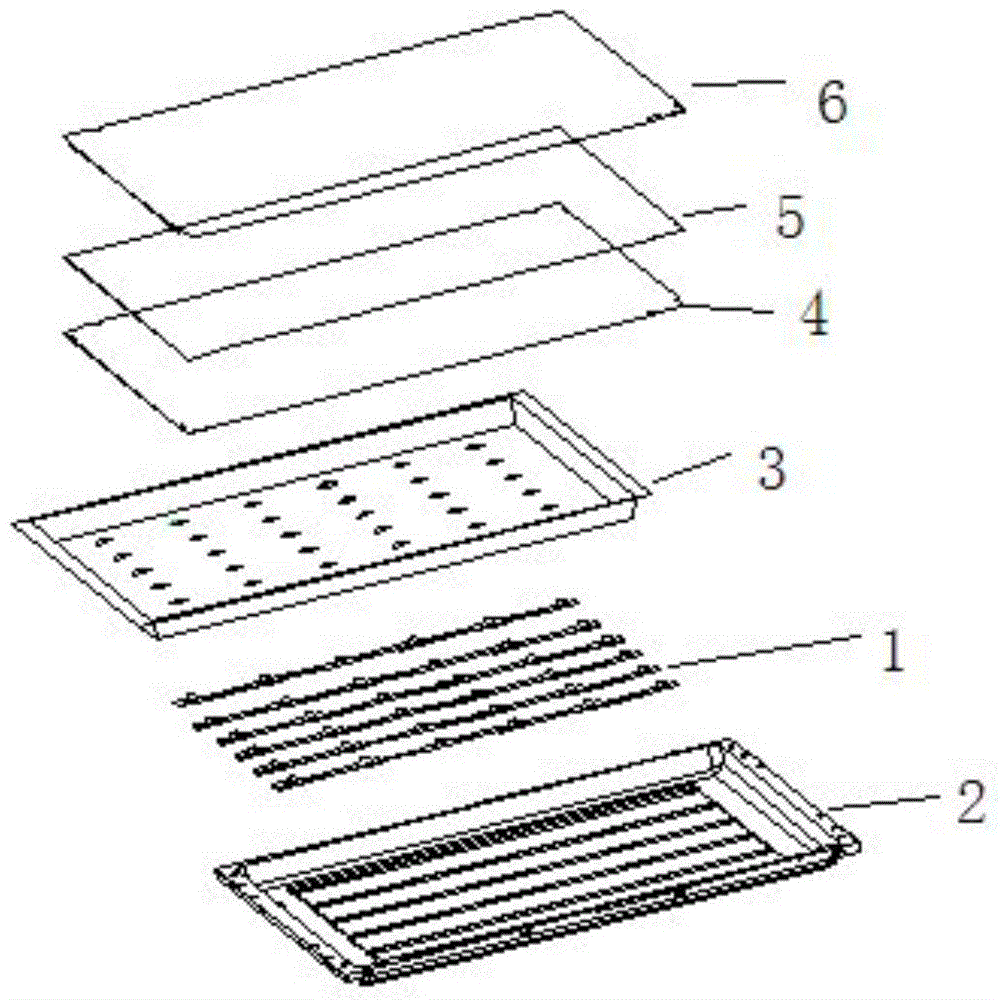

[0024] Such as Figure 6 As shown, a PCB, which is used in a direct type backlight module, is characterized in that the upper surface of the solder resist layer of the PCB 12 has a plurality of dots 14, and the dots 14 are arranged layer by layer with the LED pad 17 as the center. The distribution range of 14 is limited in the secondary optical lens silk screen 16 on the PCB12. The secondary optical lens silk screen 16 is the position where the secondary optical lens 13 is installed on the PCB 12, and the dots 14 are distributed in the secondary optical lens silk screen 16, so that the dots 14 of all facilities can play an effective role. The shape of the distribution range of the dots 14 is circular, and the diameter of the dots 14 is 0.5 mm. The dots 14 around the LED pad 17 absorb light unevenly, which can weaken the light near the LED lamp 11 and relatively improve the reflection of light away from the LED lamp 11, so that the light of the backlight module using the PCB i...

Embodiment 2

[0026] Such as Figure 7 As shown, a PCB, which is used in a direct type backlight module, is characterized in that the upper surface of the solder resist layer of the PCB 12 has a plurality of dots 14, and the dots 14 are arranged layer by layer with the LED pad 17 as the center. The distribution range of 14 is limited in the secondary optical lens silk screen 16 on the PCB12. The secondary optical lens silk screen 16 is the position where the secondary optical lens 13 is installed on the PCB 12, and the dots 14 are distributed in the secondary optical lens silk screen 16, so that the dots 14 of all facilities can play an effective role. The shape of the distribution range of the dots 14 is square, and the diameter of the dots 14 is 1.5 mm. The dots 14 around the LED pad 17 absorb light unevenly, which can weaken the light near the LED lamp 11 and relatively improve the reflection of light away from the LED lamp 11, so that the light of the backlight module using the PCB is ...

Embodiment 3

[0028] Such as Figure 8 As shown, a PCB is used in a direct-type backlight module. There are a plurality of dots 14 on the upper surface of the solder resist layer of the PCB 12. The dots 14 are arranged layer by layer with the LED pad 17 as the center. The distribution range of the dots 14 is It is limited within the silk screen 16 of the secondary optical lens on the PCB12. The secondary optical lens silk screen 16 is the position where the secondary optical lens 13 is installed on the PCB 12, and the dots 14 are distributed in the secondary optical lens silk screen 16, so that the dots 14 of all facilities can play an effective role. The shape of the distribution range of the dots 14 is rhombus, and the diameter of the dots 14 is 2 mm. The dots 14 around the LED pad 17 absorb light unevenly, which can weaken the light near the LED lamp 11 and relatively improve the reflection of light away from the LED lamp 11, so that the light of the backlight module using the PCB is mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com