Mouse cable winding and looping tool

A mouse wire and tooling technology, which is applied in transportation and packaging, delivery of filamentous materials, and thin material processing, etc., can solve the problems of poor mouse wire consistency and low work efficiency, and achieve the effect of high work efficiency and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

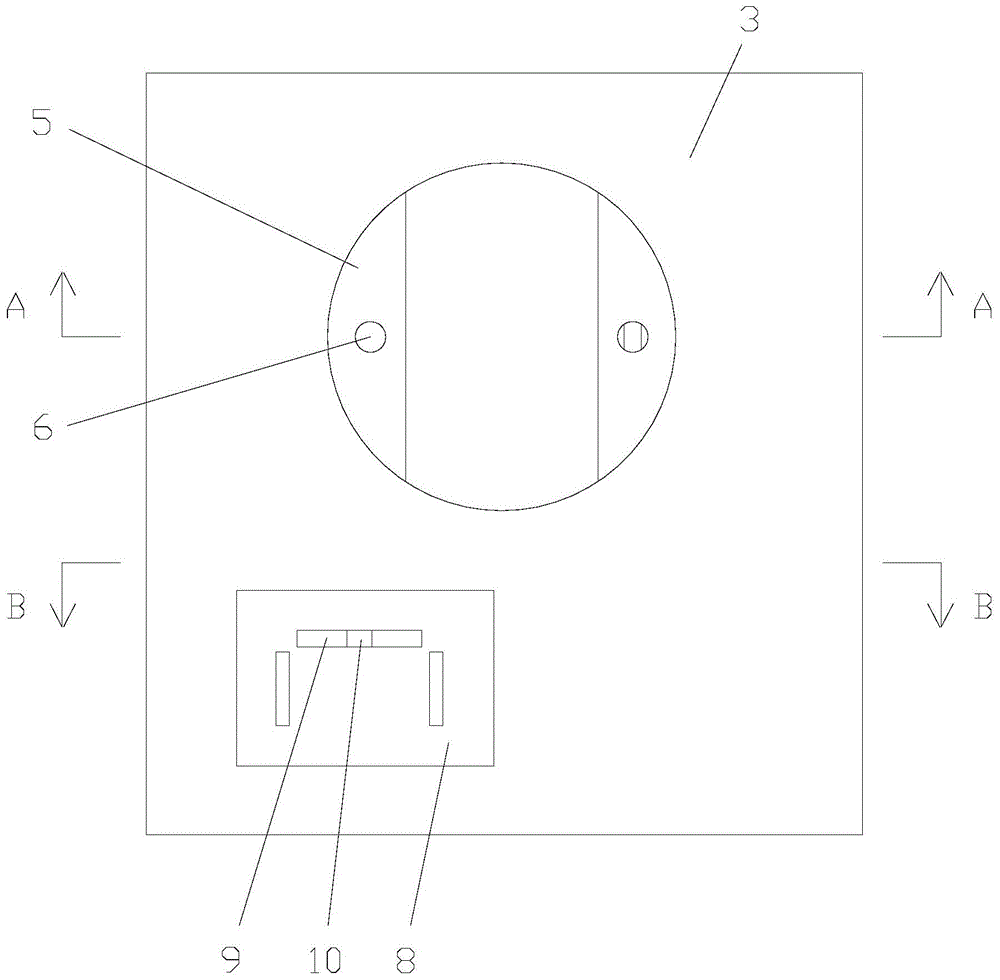

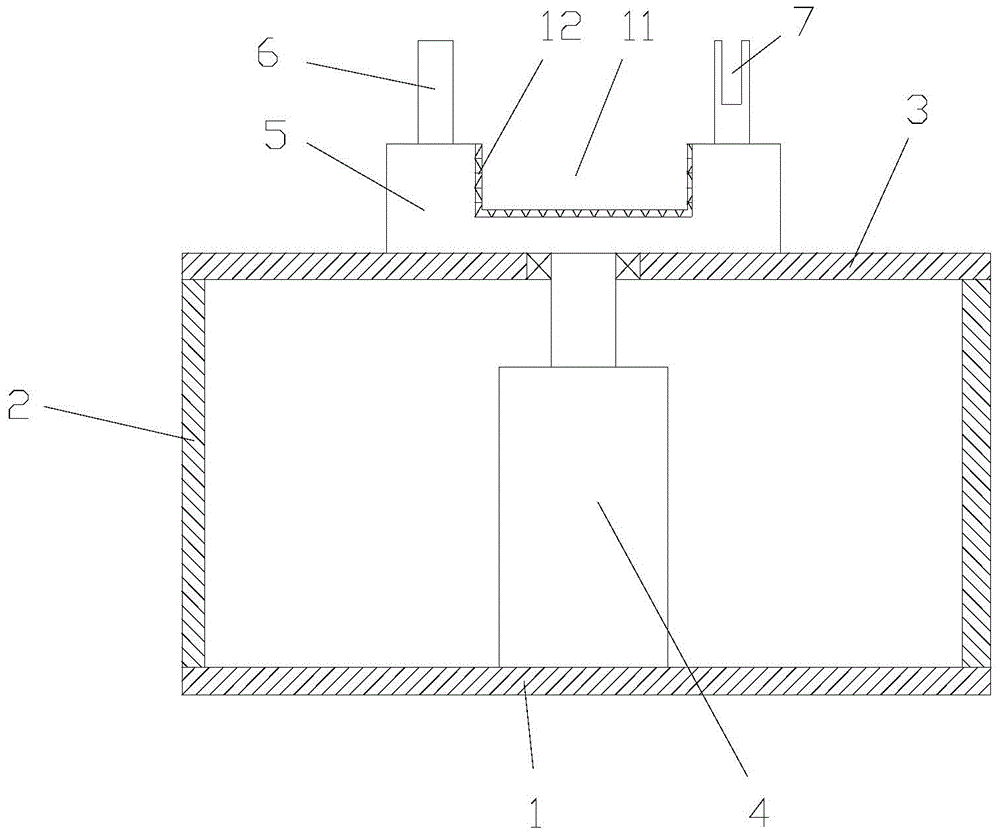

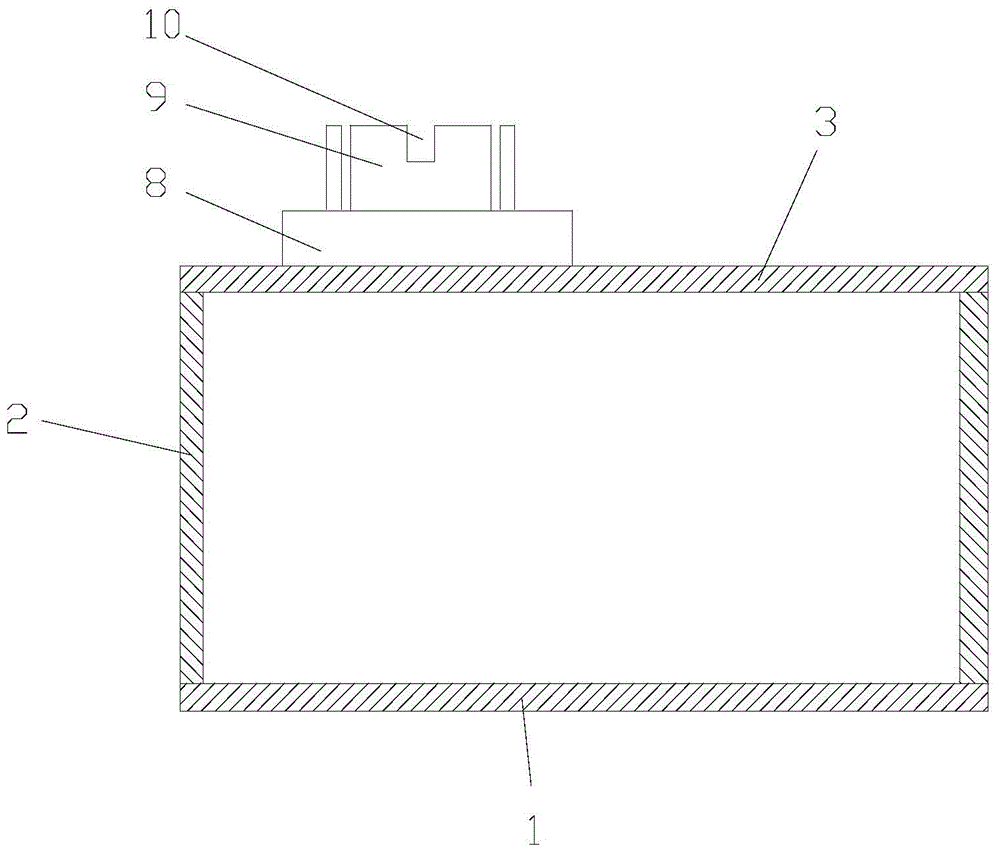

[0014] As shown in the figure, the mouse line of this embodiment is gathered and circled, including a base plate 1, a horizontal workbench 3 fixed on the base plate through a support plate 2, and a motor 4 arranged on the base plate. There is a turntable 5 connected to one end of the workbench where the rotor shaft passes vertically upwards and horizontally out of the worktable. Two cylindrical rods 6 are evenly arranged on the turntable along the circumferential direction. Of course, the number of cylindrical rods can also be more than two. For other numbers, one of the cylindrical rods is provided with an axial slot 7;

[0015] It also includes a mouse positioning device arranged on the horizontal workbench. The mouse positioning device includes a backing plate 8 and three baffles 9 arranged in a U shape on the backing plate, wherein the baffle at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com