Multi-mode amplitude control system of crank arm type overhead working truck

A high-altitude operating vehicle and amplitude control technology, which is applied in the mechanical field, can solve the problems of affecting work efficiency, poor adaptability, and inability to adapt to various working conditions, and achieve the effect of flexible control system and simple and single amplitude control mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

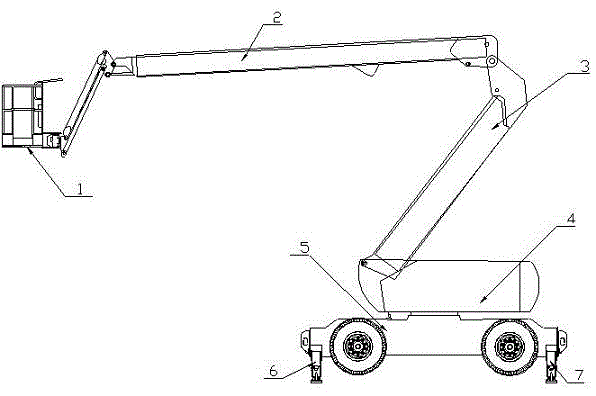

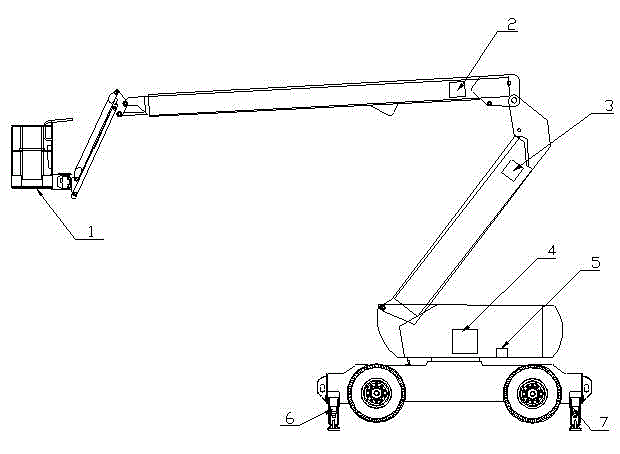

[0037] 1 Introduction to the structure of the multi-mode amplitude control system

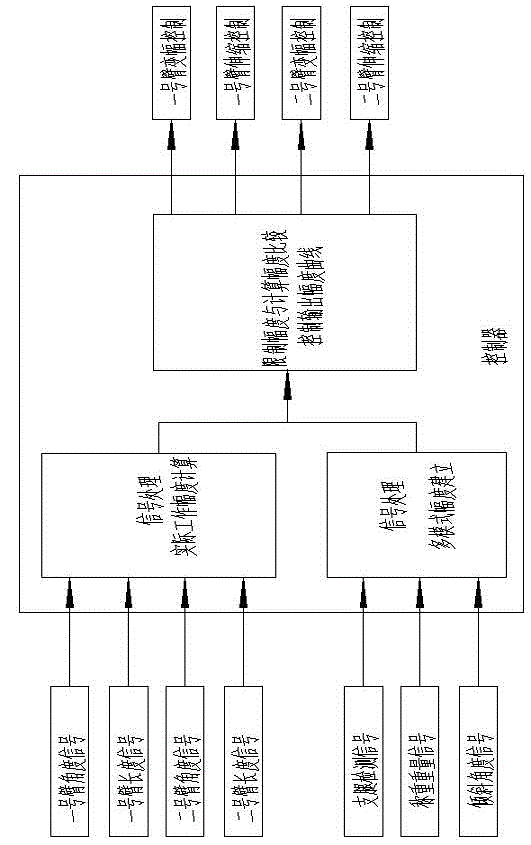

[0038] like figure 2 As shown in the figure, the system mainly includes a platform weighing sensor 1, a second arm length and angle sensor 2, a first arm length and angle sensor 3, a dual-axis inclination sensor 5, a front outrigger force detection device 6, and a rear outrigger force The detection device 7 and the vehicle controller 4 .

[0039] The platform load cell 1 is installed on the working platform and is used to detect the total weight of the workers and tools on the working platform. In this system, two modes of weight participation amplitude control are set, namely weight W1 and weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com