A locking system for the bottom door of a railway hopper car

A technology for hopper cars and bottom doors, which is applied to hopper cars, railway car body parts, transport passenger cars, etc. It can solve problems such as low unloading efficiency, bent lock pins, and accidental opening of bottom doors to ensure vehicle operation and personnel safety , prevent derailment and overturning, check and maintain the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is specifically described below through the examples, the examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention, some non-essential improvements made by those skilled in the art according to the contents of the above-mentioned invention And adjustments also belong to the protection scope of the present invention.

[0054] combine Figure 1 to Figure 18 .

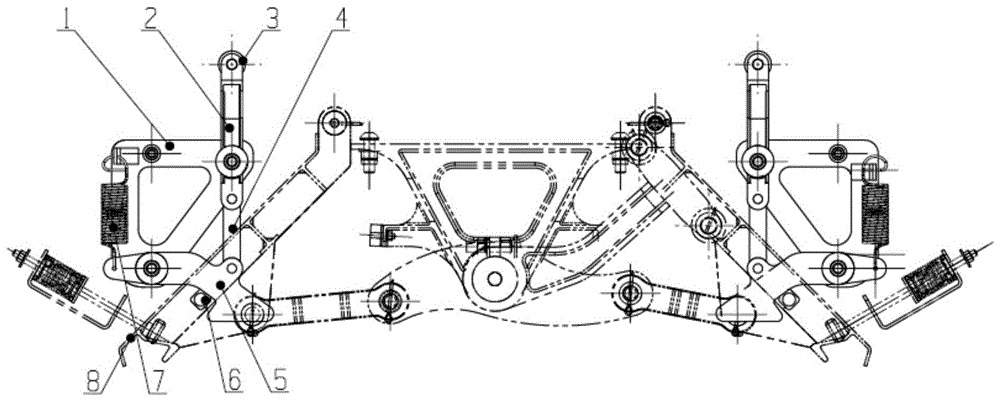

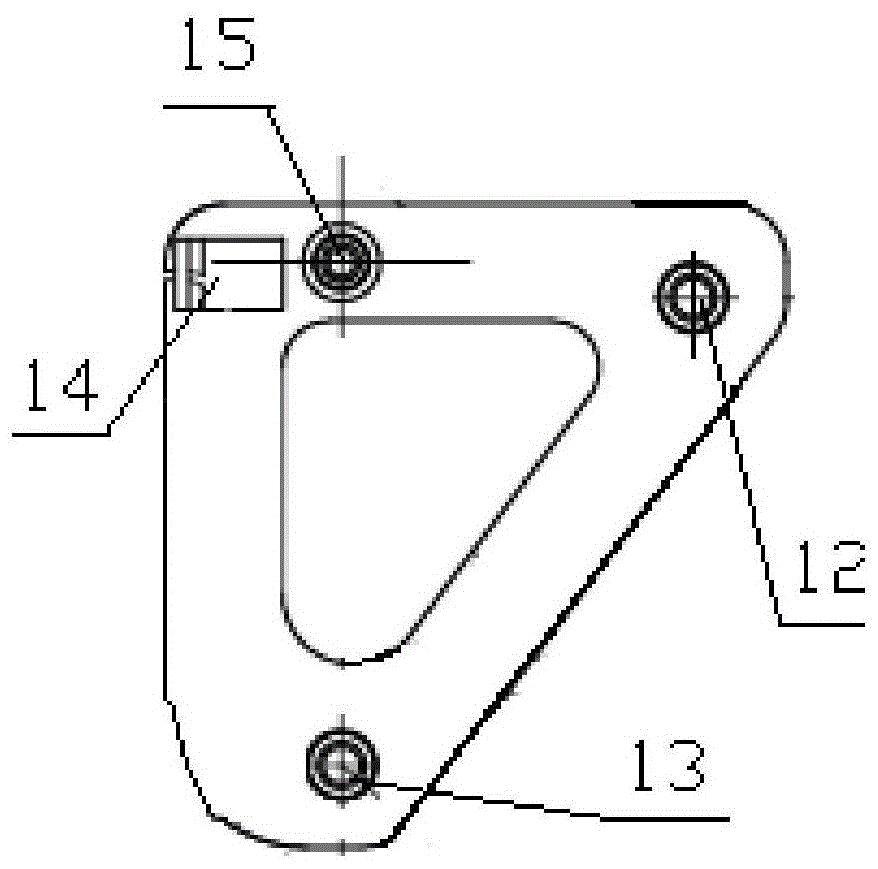

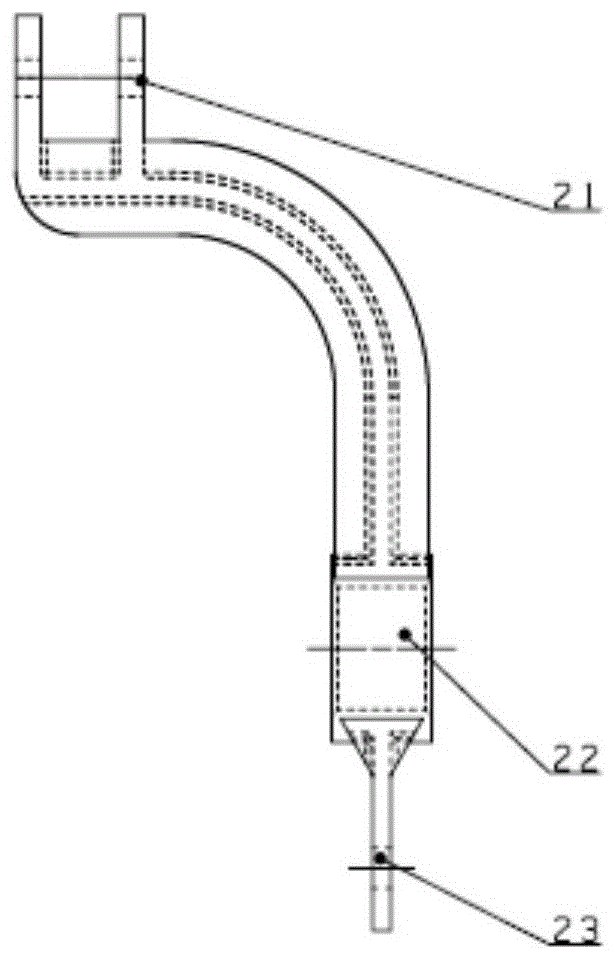

[0055] The locking system includes a bottom door arranged at the bottom of the hopper car, a primary locking device and a secondary locking device, and also includes a ground collision device installed on the ground to cooperate with the locking device to realize the opening and closing of the locking device, and the secondary locking device The device is a four-bar linkage transmission mechanism with a motion dead point.

[0056] The four-link transmission mechanism includes a seat plate 1, an unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com