Breaker with arc extinguishing device

An arc extinguishing device and circuit breaker technology, which is applied to circuit breaker parts and other directions, can solve problems such as unreasonable exhaust channel design, arc re-ignition, arc breakdown, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

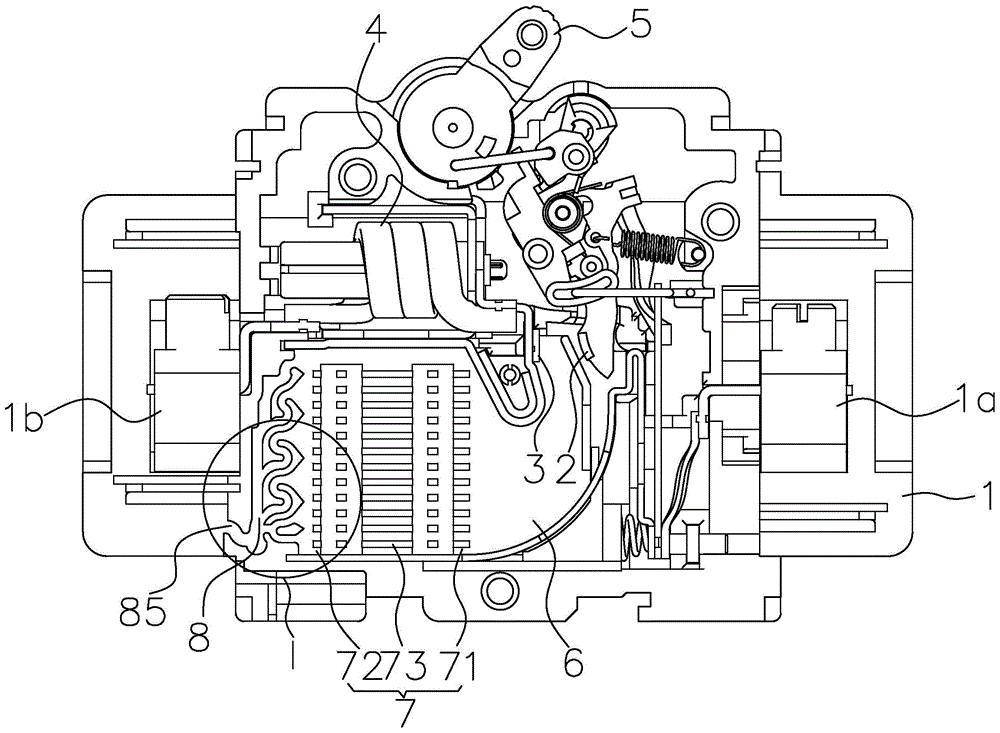

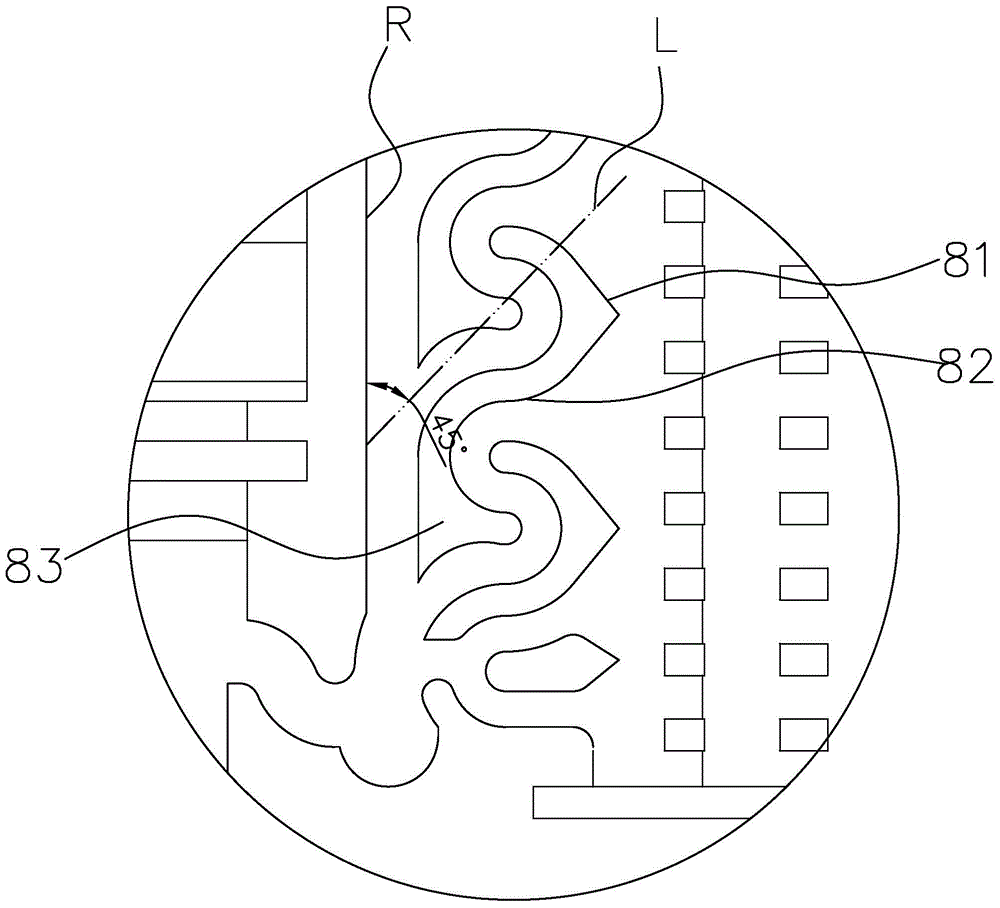

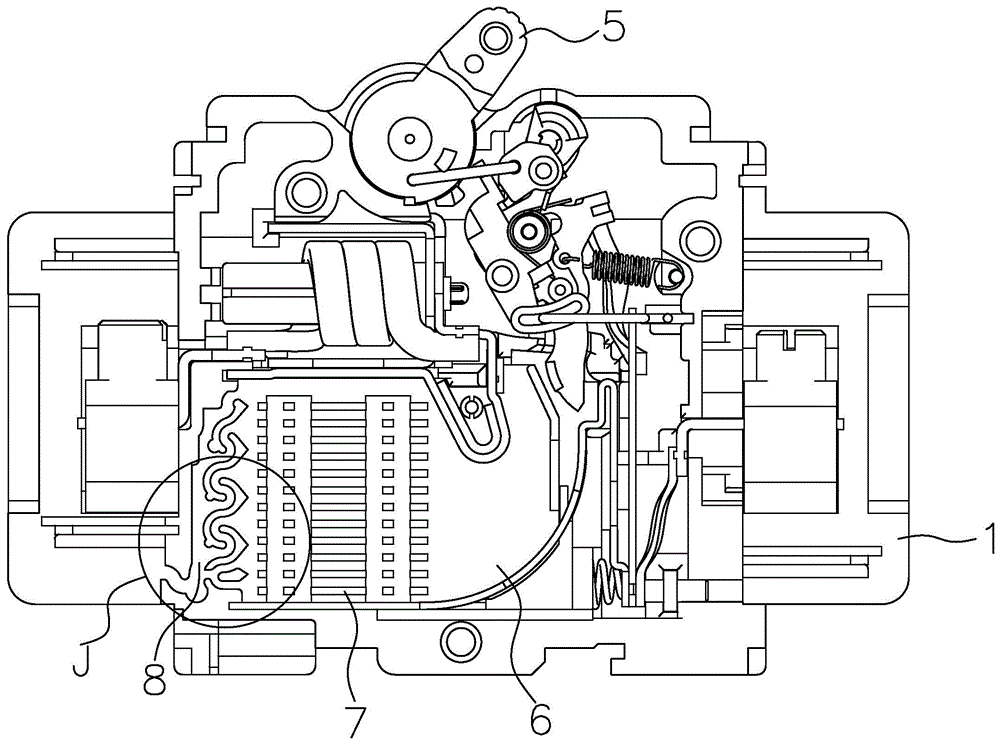

[0024] refer to figure 1 , figure 2 and Figure 5 , Embodiment 1 of the present invention discloses a circuit breaker with an arc extinguishing device, including a housing 1 and a static contact 2, a moving contact 3, an electromagnetic release 4, an arc extinguishing device and an operating mechanism 5 disposed in the housing. , as a known structure, wherein the movable contact 3 is double controlled by the operating mechanism 5 and the electromagnetic release 4. In the on state, the current passes through the terminal 1a, the static contact 2, the movable contact 3, the electromagnetic The release 4 and the terminal 1b finally form a passage to the electrical equipment. An arc extinguishing device is provided in the housing 1 located in the contact part of the static contact 2 and the moving contact 3. The arc extinguishing device includes sequentially according to the direction of gas flow. The arc starting chamber 6, arc extinguishing chamber 7 and exhaust passage 8 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com