An inflator for automatically inflating cushioning packaging bags

An automatic inflation and inflator technology, applied in the direction of transportation and packaging, containers and containers to prevent mechanical damage, etc., can solve the problems of non-compliance, waste of manpower and financial resources, slow speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

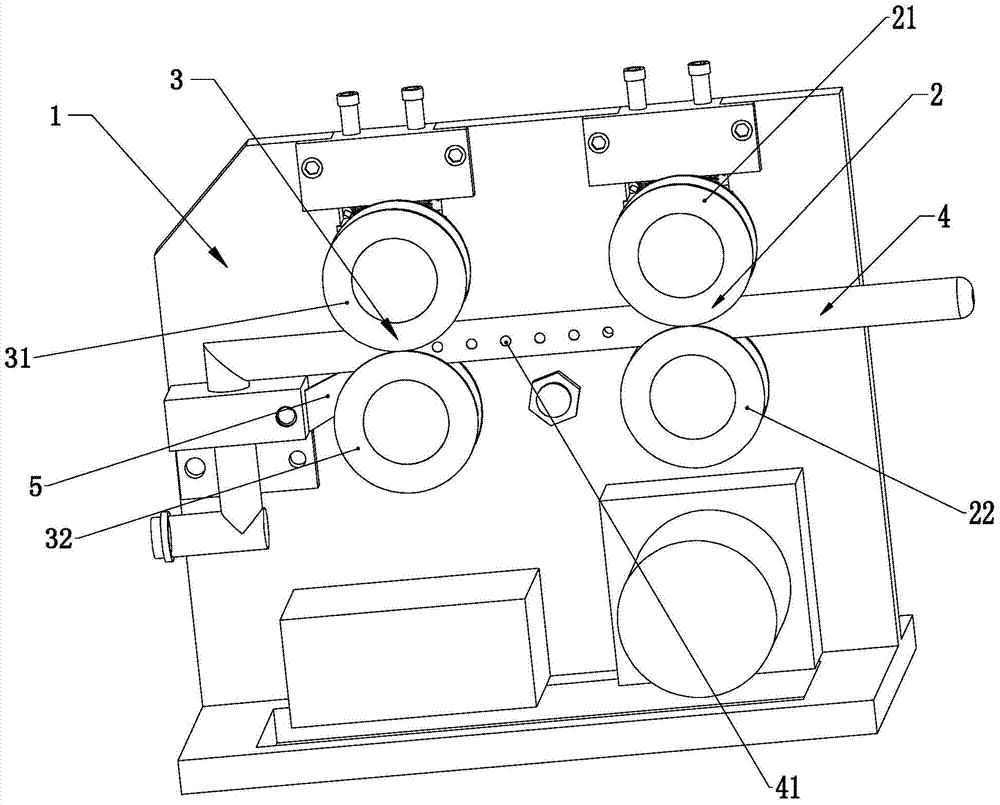

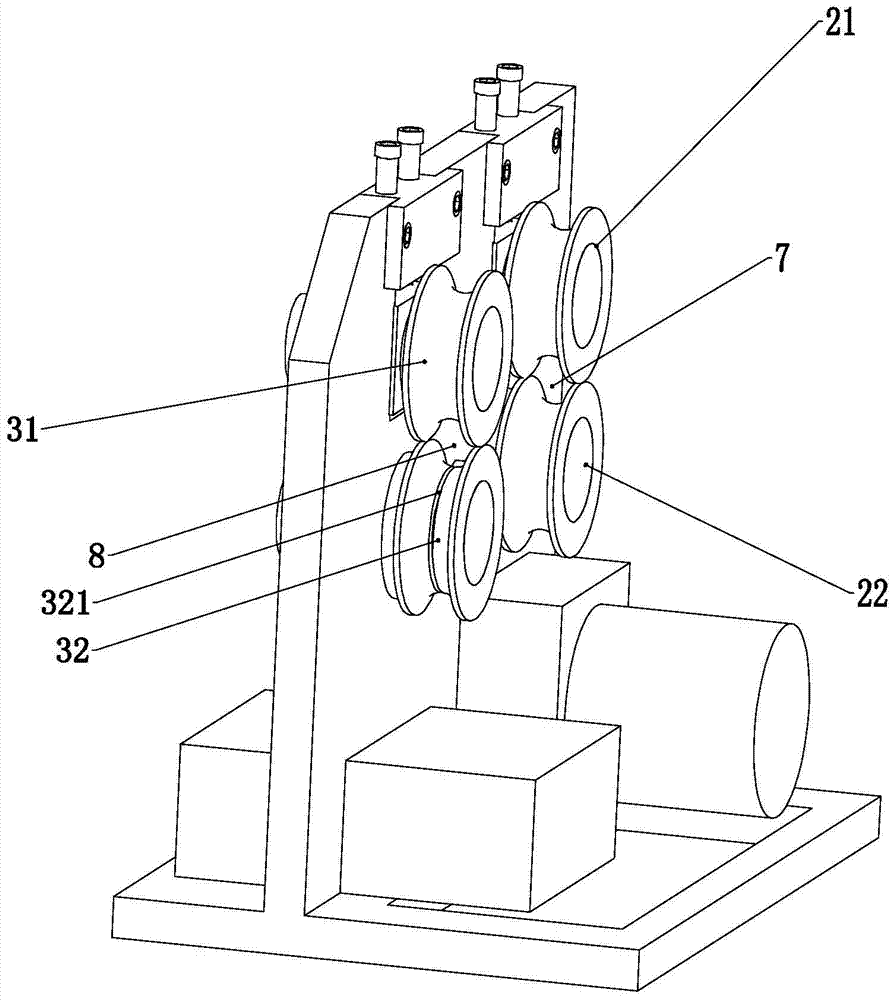

[0019] Such as figure 1 — Figure 4 As shown, an inflator for automatically inflating cushioning packaging bags includes a bracket 1, and one side of the bracket 1 is provided with a first pressure roller set 2 and a second pressure roller set 3, and the first pressure roller set 2 includes The first upper pressure roller 21 and the first lower pressure roller 22, the second pressure roller group 3 includes the second upper pressure roller 31 and the second lower pressure roller 32, the first upper pressure roller 21, the first lower pressure roller 21. The outer peripheral surfaces of the second upper pressure roller 31 and the second lower pressure roller 32 are concave arc surfaces, and the two pressure rollers of the first pressure roller set 2 and the two pressure rollers of the second pressure roller set 3 are arranged between There is a guide inflation pipe 4, one end of the guide inflation pipe 4 passes between the first upper pressure roller 21 and the first lower pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com