Predictive control method of knee joint of active upper-knee prosthesis

A technology of predictive control and knee joints, applied in prosthesis, medical science, etc., can solve the problems of poor real-time performance, low timeliness, unfavorable active prostheses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

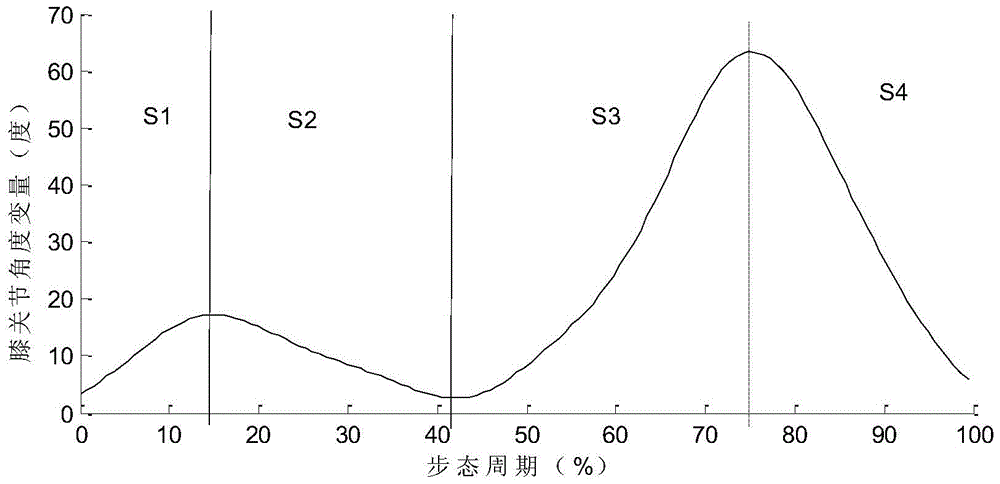

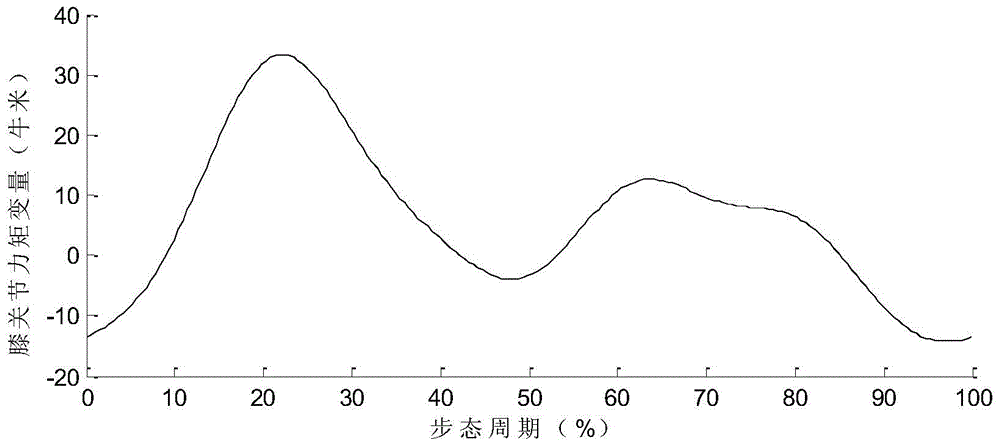

[0126] The predictive control method of the knee joint of the active knee prosthesis, the steps are as follows:

[0127] The first step is to collect the basic information data of the required experimenters offline and generate a data report:

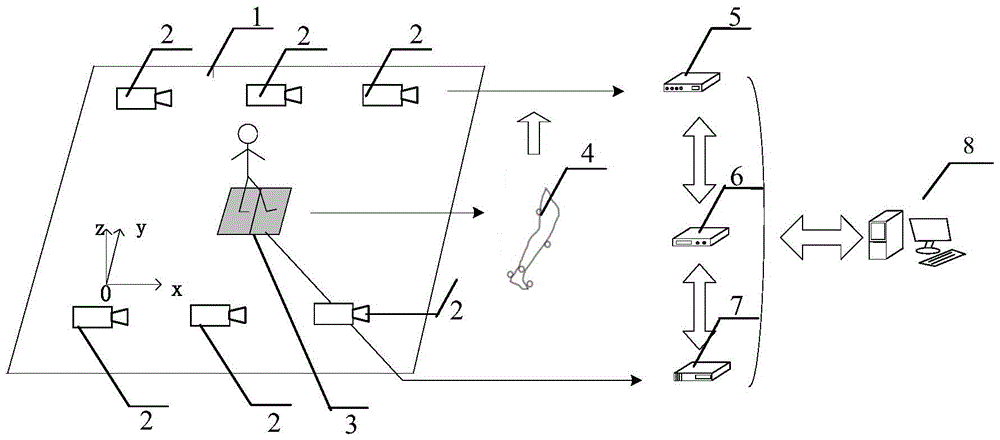

[0128] Using Vicon MX 3D gait analysis system including 6 high-speed MX infrared camera heads, MX components, PC host and MX peripheral kit, the left and right sides of the six lower limbs, namely knee joint, thigh, calf, ankle joint, toe and heel Paste 6 infrared reflective points, according to the infrared reflective points pasted on the above positions, input the basic information of the experimenter's height, weight, leg length, hip width, knee joint width and ankle joint width into the above-mentioned Vicon MX three-dimensional gait analysis In the system, the static model is initialized first, after the above basic information is collected, the missing marker points are filled in and the walking video is simulated in the software ...

Embodiment 2

[0154] Except that in the second step of establishing the segmented affine system model of the knee joint motion of the lower limb prosthesis, the two curves are divided into corresponding 27 segments, the others are the same as in the first embodiment.

Embodiment 3

[0156] Except that in the second step of establishing the segmented affine model of the knee joint motion of the lower limb prosthesis, the two curves are divided into corresponding 50 segments, the others are the same as in the first embodiment.

[0157] All the equipment used in the above examples are obtained from known channels.

[0158] The VICON MX three-dimensional gait analysis system described in the above-mentioned embodiment comprises sensor, signal acquisition equipment, data transmission equipment, data processing equipment four parts as follows:

[0159] a. The sensor part includes: a reflective ball 4 with a diameter of 14mm, used to mark the position of the moving point; a force measuring plate 3 with a size of 464×508mm, used for collecting mechanical information.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com