Method for soldering a connection element

A technology for connecting components, brazing, applied in the field of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

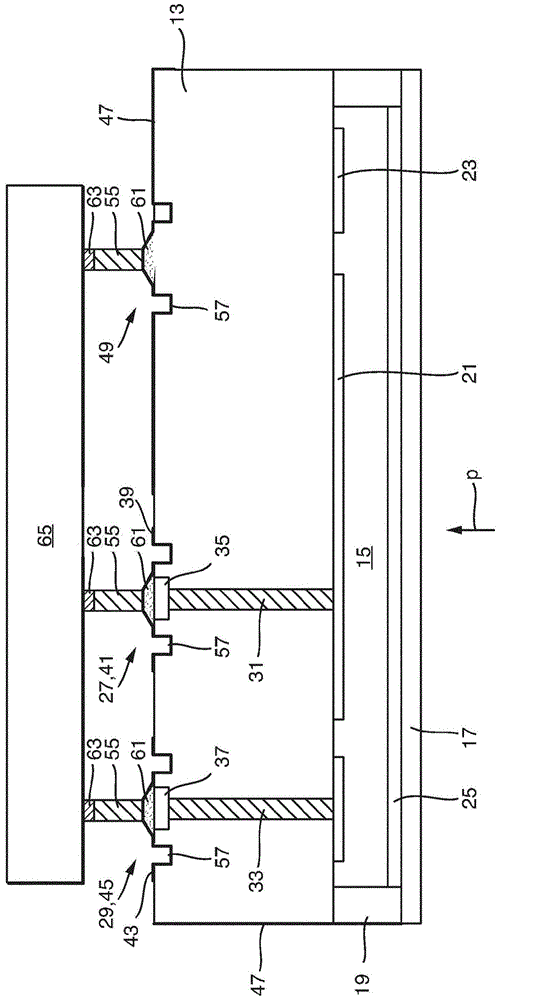

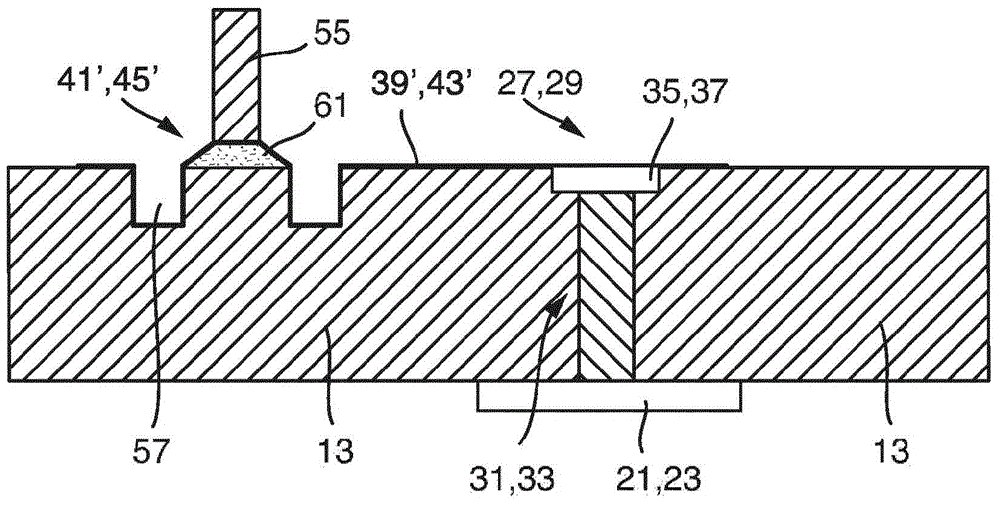

[0060] For purposes of illustrating the invention, figure 1 A cross-section of a base body 1 is shown with a conductive coating 3 suitable for soldering applied to its outer insulating surface. For example, the base body 1 consists entirely of an insulating material, in particular a ceramic material (in particular aluminum oxide) or an insulating plastic or the like. Alternatively, the base body 1 can also consist of an electrically conductive material provided with an insulating layer on the outside, for example metal coated with an insulating layer.

[0061] A spatially restricted connection point 5 is arranged on the coating 3 of the base body 1 , via which connection point 5 a connecting element (not shown here) is connected to the coating 3 by means of an electrically conductive solder joint.

[0062] According to the invention, a recess 7 is provided in the base body 1 which at least partially surrounds the connection point 5 on the outside. The groove 7 is formed as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com