Pipe connector with self-sealing and quick insertion and extraction functions

A technology of pipe joints and plugs, applied in mechanical equipment, couplings, etc., can solve the problems of poor oxygen supply capacity, poor organizational coordination, and inability to uniformly guarantee, so as to achieve firm locking and good force bearing. , the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

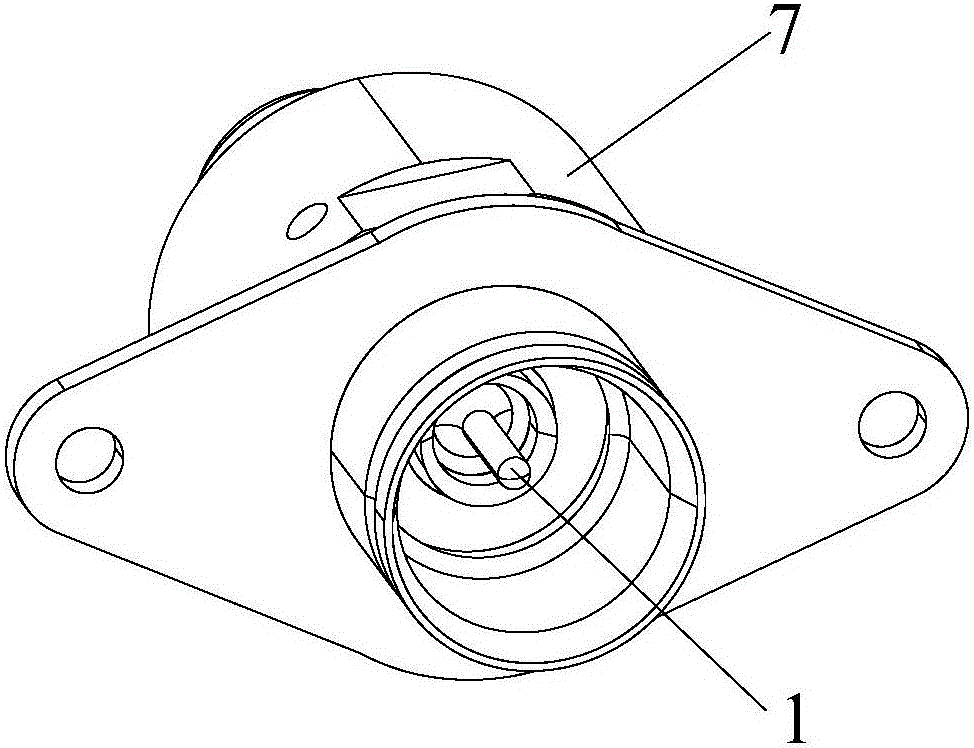

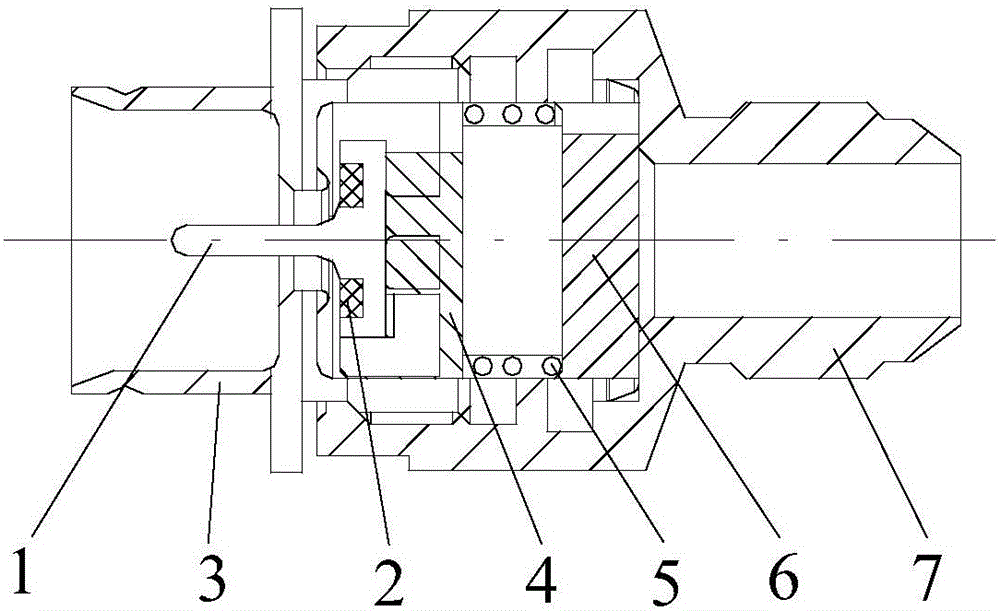

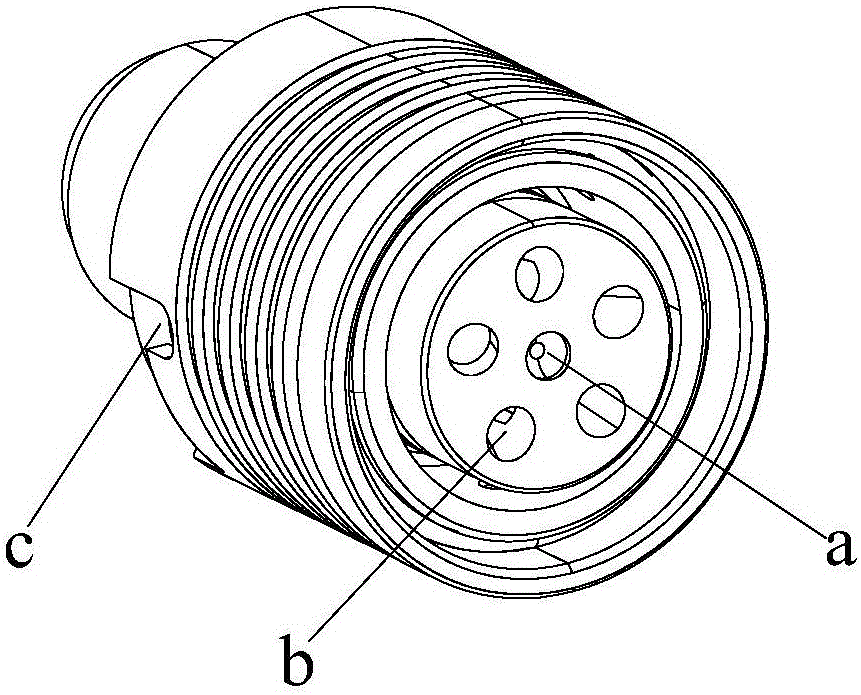

[0022] like Figure 1-Figure 6 As shown, the pipeline joint with self-sealing quick plug-in function of the present invention includes a socket 7 and a plug 13 .

[0023] A gas channel is provided inside the socket 7, a moving block 6 and a valve d are provided at the entrance of the gas channel, and a thimble 1 is provided at the outlet of the gas channel, the thimble 1 is connected with the slider 4, and a first valve is provided between the thimble 1 and the slider 4. The compression spring 5 is provided with an outer sleeve 3 at the end of the seat body, and the end of the thimble 1 extends into the outer sleeve 3, and the outer sleeve 3 is provided with a slot f. A rubber pad 2 is provided on the contact surface b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com