Ink supply system of ink jet printer

An inkjet printer and inkjet printing technology, applied in printing and other directions, can solve the problems of insufficient working efficiency, high cost of ink cartridges, and trouble for users to use, so as to improve the lack of ink supply, provide accuracy, and achieve environmentally friendly printing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

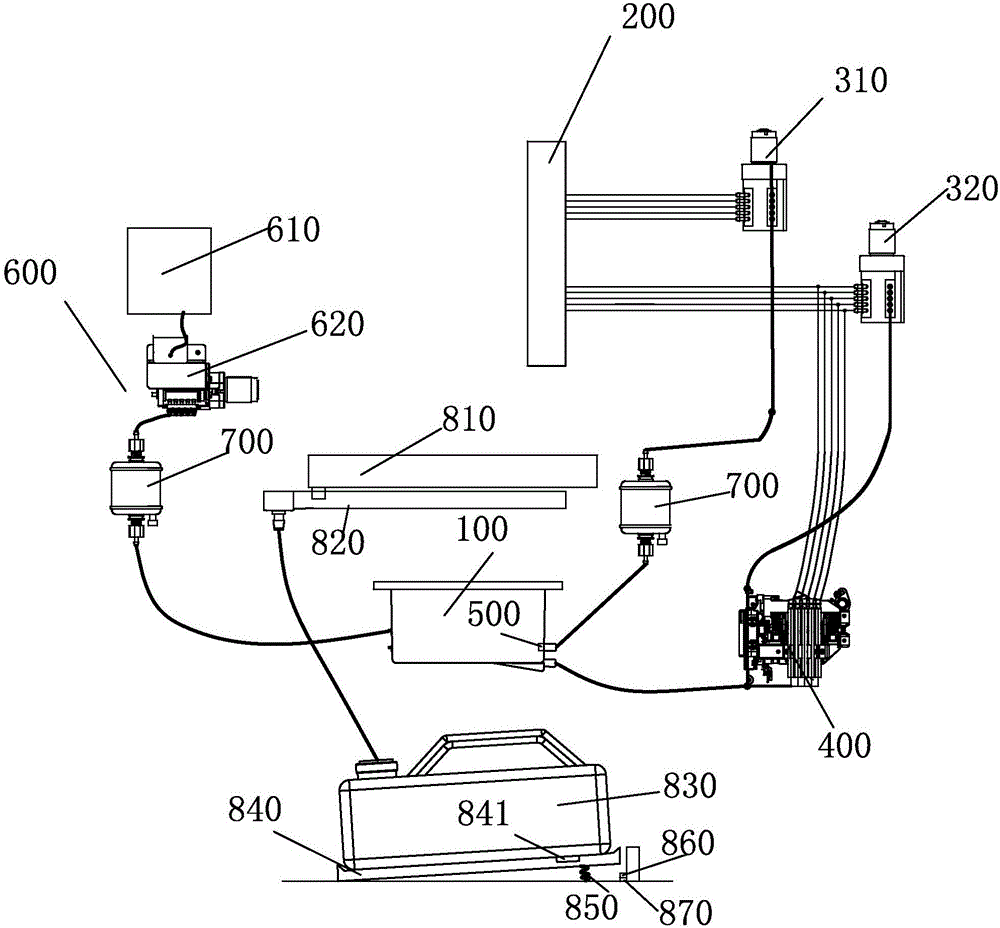

[0034] like figure 1 As shown, an ink supply system of an inkjet printer includes an inkjet head 200 for inkjet printing; a central ink tank 100 for providing ink to the entire system; two ink pumps, including a first ink pump 310 And the second ink pump 320, wherein the first ink pump 310 and the second ink pump 320 are connected with the inkjet head 200 through the ink tube, the first ink pump 310 communicates with the central ink tank 100 through the ink tube, and the second ink pump 320 is connected with the central ink tank An ink valve 400 is provided between 100 , and the second ink pump 320 is connected to the central ink tank 100 through the ink valve 400 .

[0035] When the ink valve 400 is open, it is the ink supply state, the first ink pump 310 draws ink from the central ink tank 100 to the inkjet head 200, and the second ink pump 320 draws ink from the central ink tank 100 to supply ink to the ink jet through the ink valve 400 Head 200; when the ink valve 400 is ...

Embodiment 2

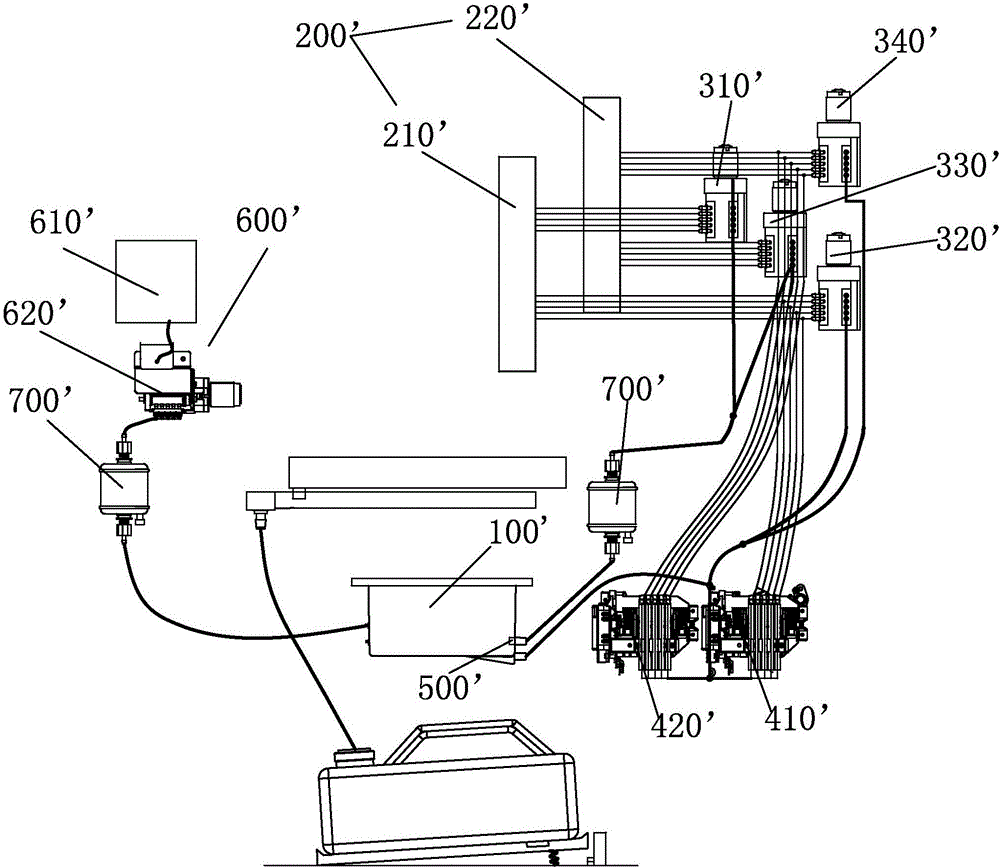

[0045] An ink supply system for an inkjet printer, comprising two inkjet heads 200' for inkjet printing; a central ink tank 100' for providing ink to the entire system; four ink pumps, including a first ink pump 310' , the second ink pump 320', the third ink pump 330' and the fourth ink pump 340', wherein the first ink pump 310' and the second ink pump 320' are connected to the first inkjet head 210' through ink tubes, the second The three ink pumps 330' and the fourth ink pump 340' are connected to the second inkjet head 220' through ink tubes, the first ink pump 310' and the third ink pump 330' communicate with the central ink tank 100' through ink tubes, and the second ink There is a first ink valve 410' between the pump 320' and the central ink tank 100', the second ink pump 320' is connected to the central ink tank 100' through the first ink valve 410', and the fourth ink pump 340' is connected to the central ink tank 100' There is a second ink valve 420' between them, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap