A method of processing a frame for a sample of a knight's vehicle

A technology for a sample frame and a processing method, which is applied in the direction of metal processing equipment, manufacturing tools, auxiliary devices, etc., and can solve problems such as numerous procedures, high cost, and complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

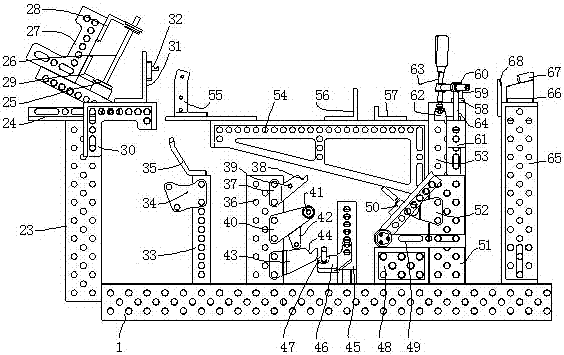

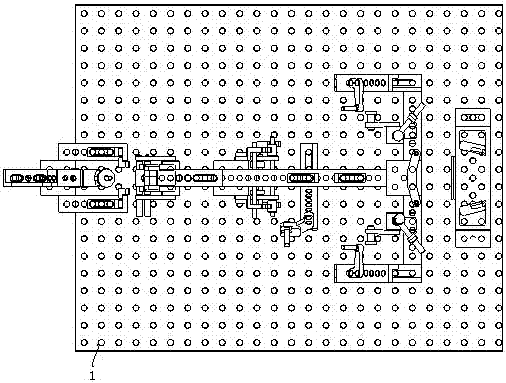

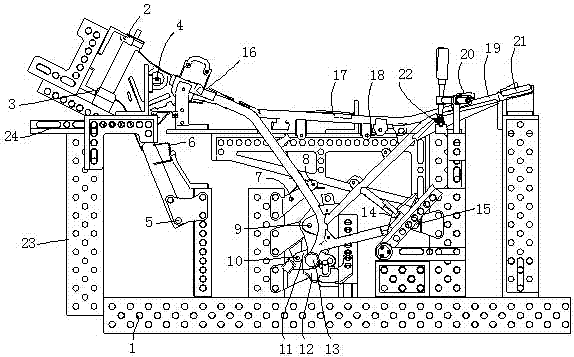

[0044] Optimum implementation mode: a frame processing method for a rider bike sample, the key point of which is to complete the separate processing of the combination of the head tube assembly and the combination of the left and right frame halves; complete the direction lock block and the direction limit Separate processing of block, fuel tank clamp shaft, engine front suspension installation shaft and hanger for lower inclined tube attachment installation; complete engine rear upper suspension installation shaft and engine rear upper suspension installation shaft lugs fixed at both ends, and front lower tube reinforcement The connecting shaft and the front lower tube fixed at both ends strengthen the connecting shaft lug, the flat fork shaft, the engine rear suspension mounting shaft and the engine rear suspension mounting shaft lug fixed at both ends, the side bracket mounting plate, and the front down tube Separate processing of the lateral connecting shaft, rear pedal lug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com