Patents

Literature

37results about How to "Convenient trial production adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

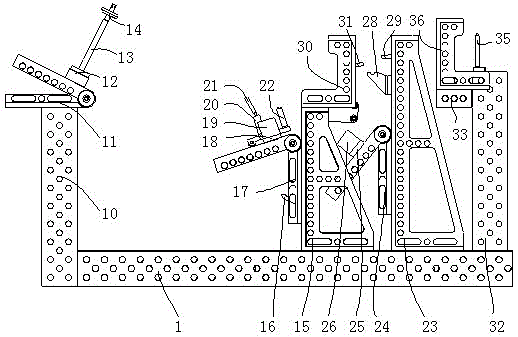

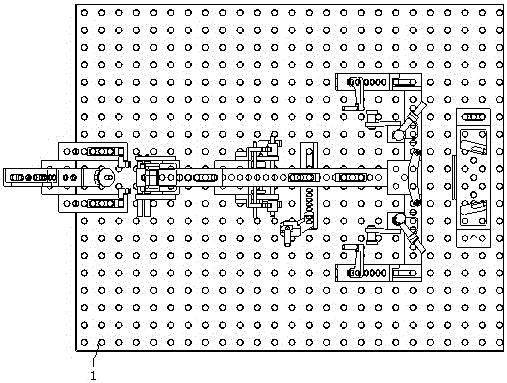

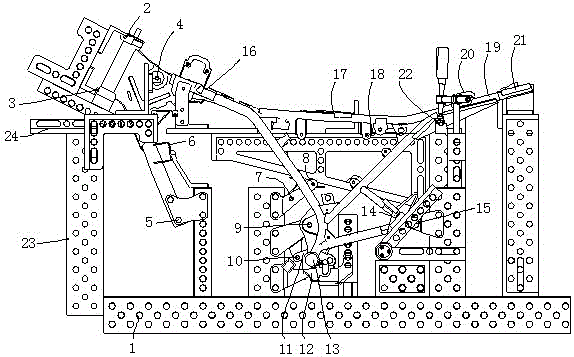

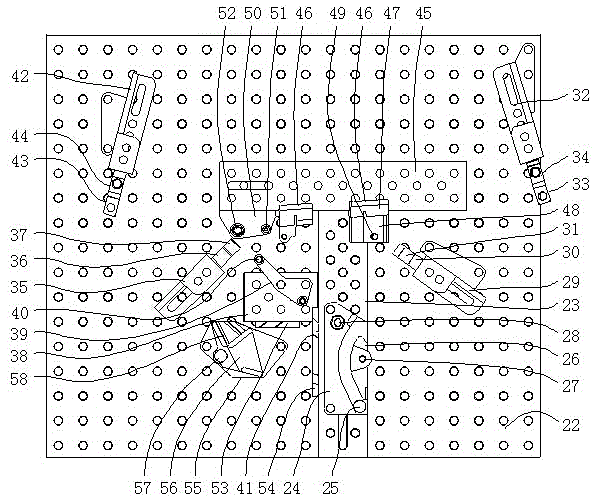

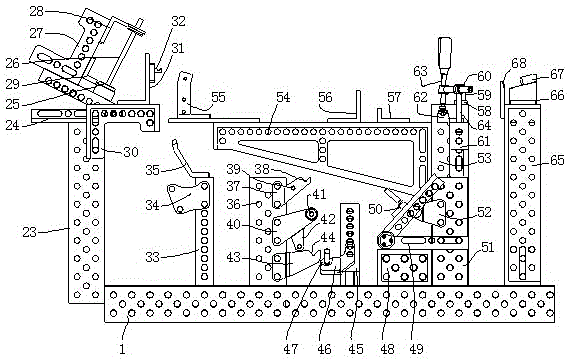

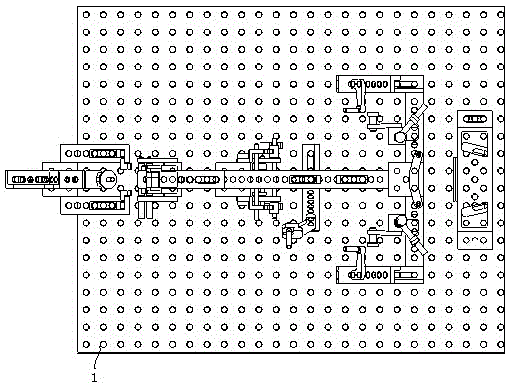

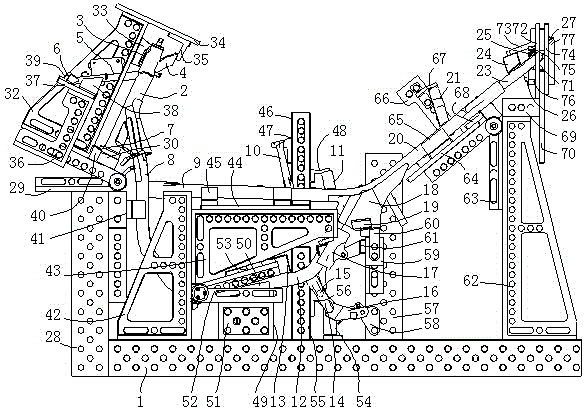

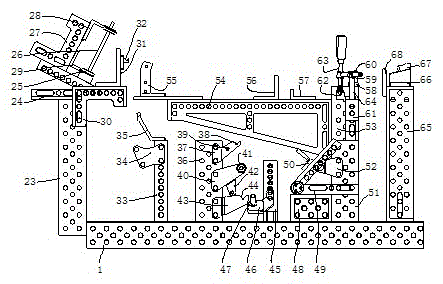

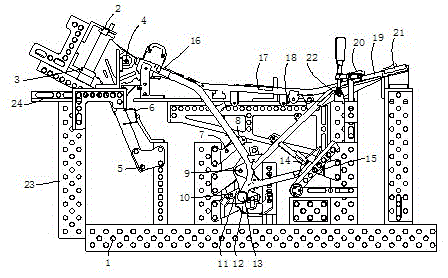

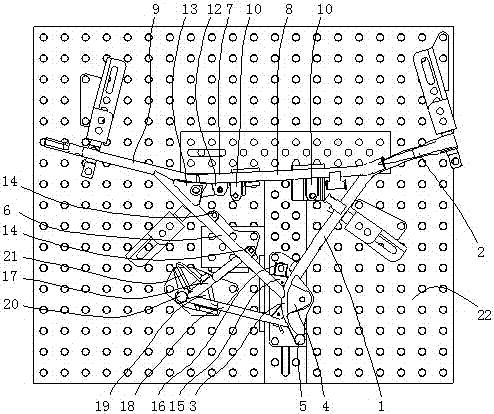

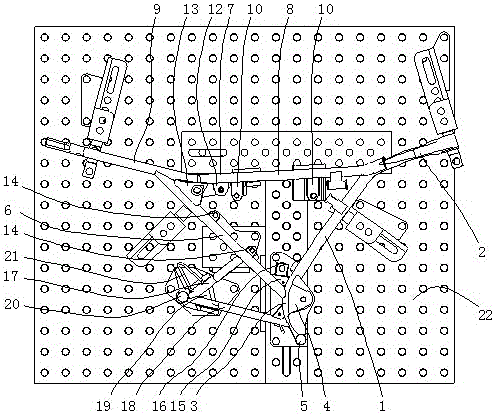

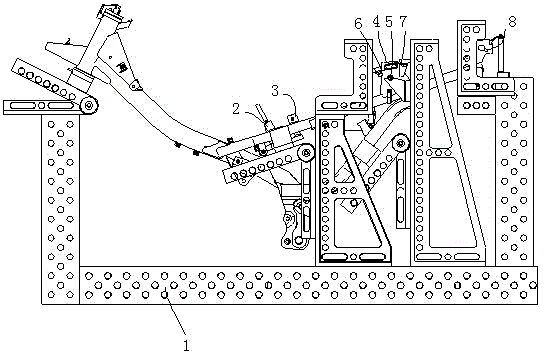

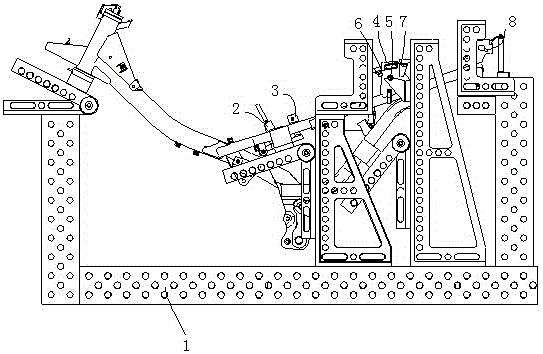

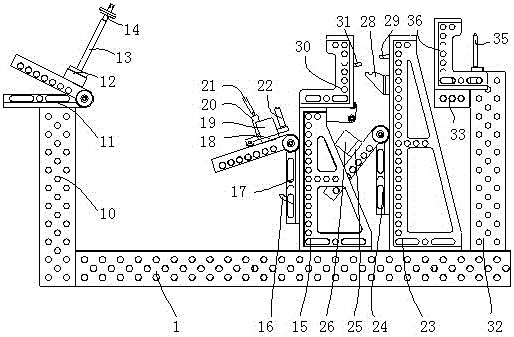

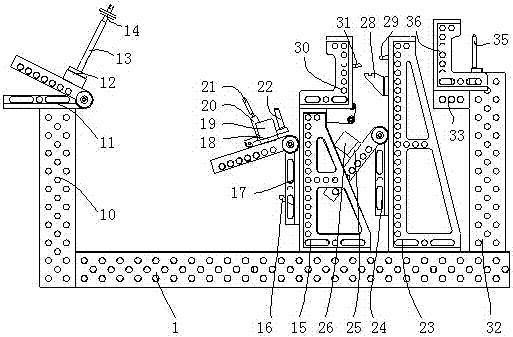

Frame welding clamp used for cub-type motorcycle sample

InactiveCN105108420AConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

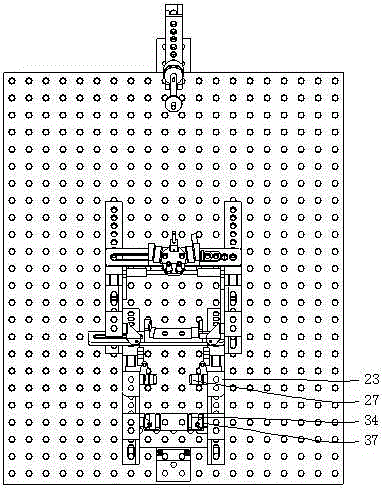

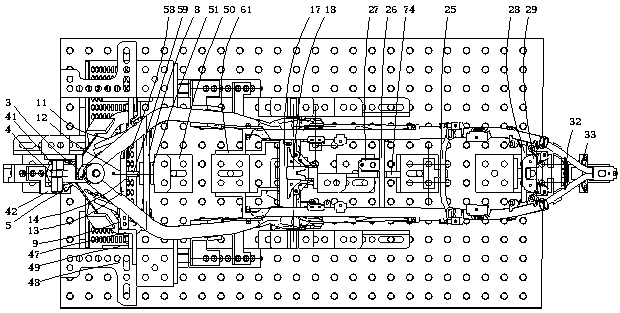

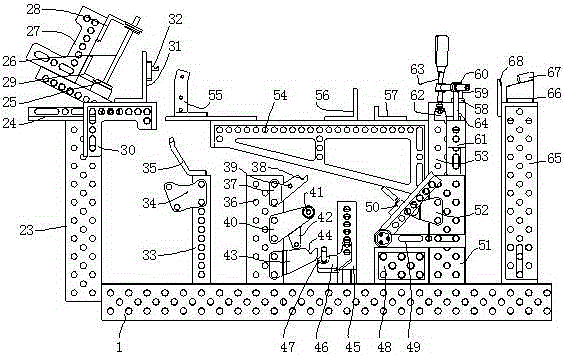

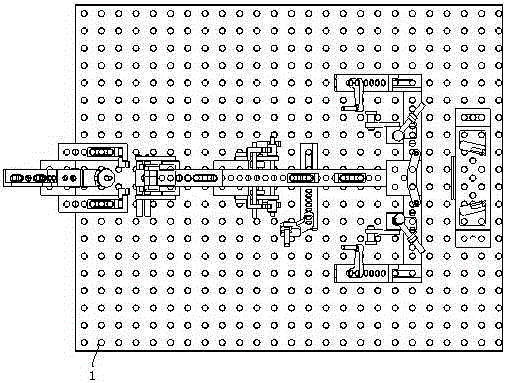

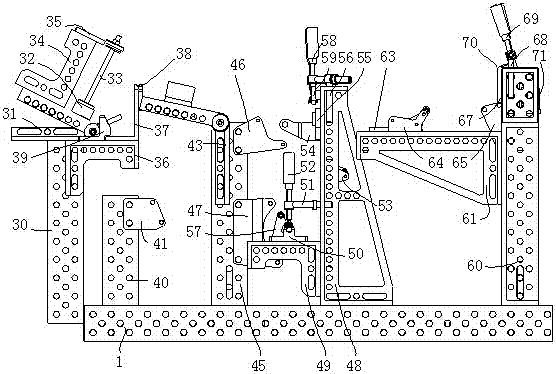

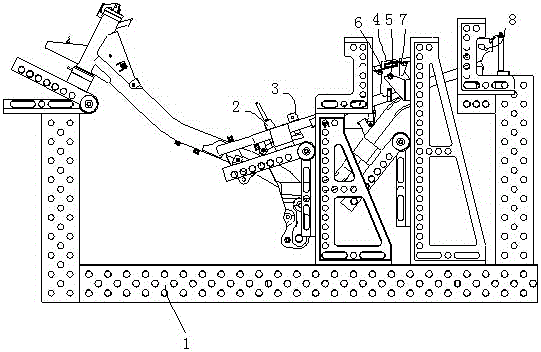

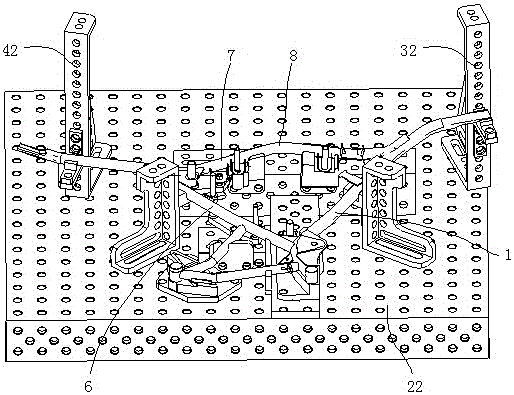

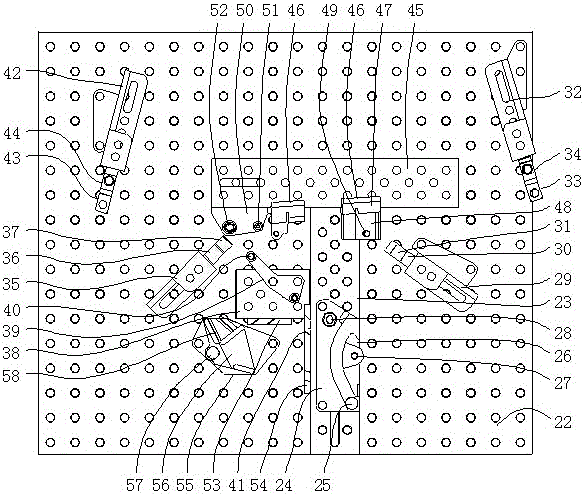

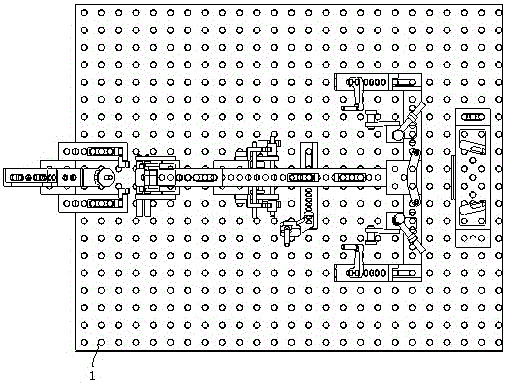

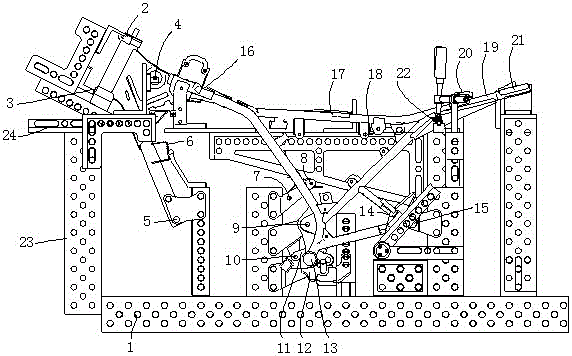

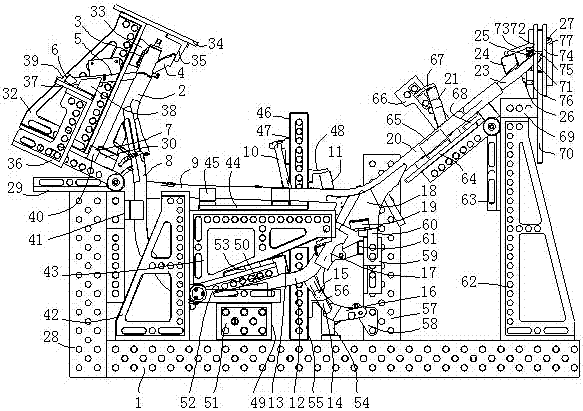

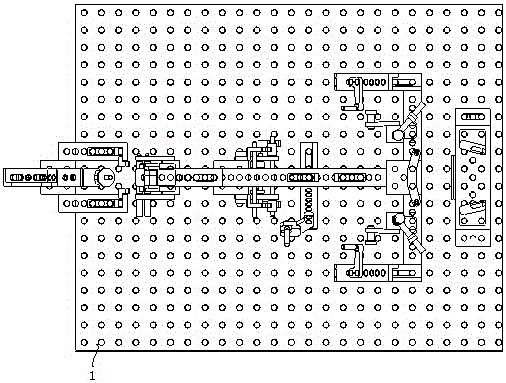

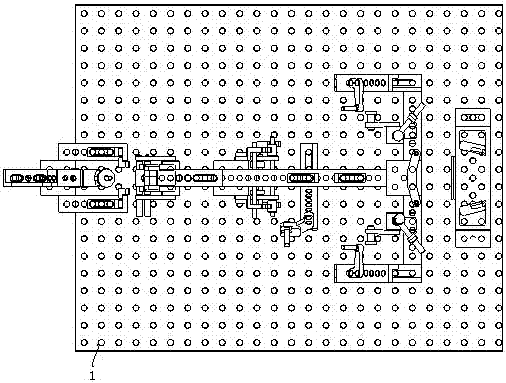

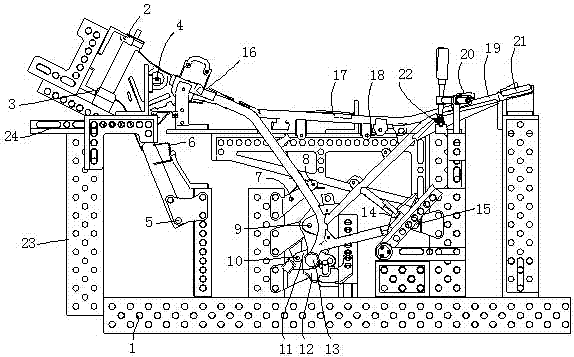

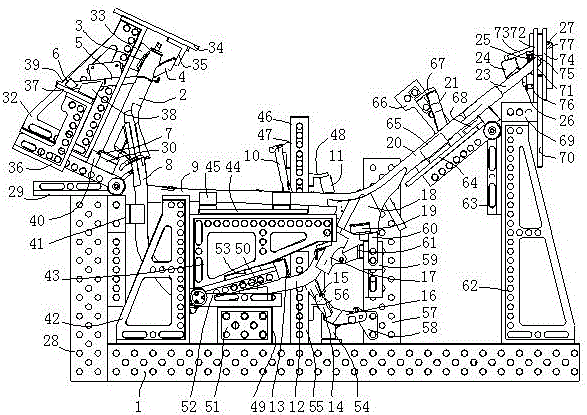

The invention discloses a frame welding clamp used for a cub-type motorcycle sample. The frame welding clamp is characterized by comprising a three-dimensional installing platform, a frame front half body positioning clamp structure, a rear beam tube front positioning welding clamp structure, a rear beam tube rear positioning welding clamp structure and a rear beam tube tail positioning welding clamp structure, wherein multiple installing holes are arrayed at a fixed distance in the upper surface and periphery side surface of the three-dimensional installing platform, and the frame front half body positioning clamp structure, the rear beam tube front positioning welding clamp structure, the rear beam tube rear positioning welding clamp structure and the rear beam tube tail positioning welding clamp structure are arranged on the three-dimensional installing platform. The welding assembly process can be simplified, and the frame welding clamp has the advantages of being easy to operate, low in cost, capable of facilitating trial-manufacture adjustment of the cub-type motorcycle sample and the like.

Owner:力帆科技(集团)股份有限公司

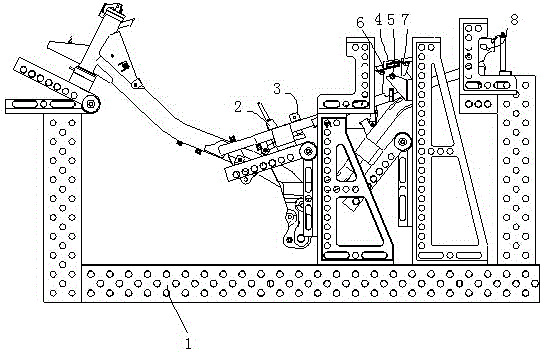

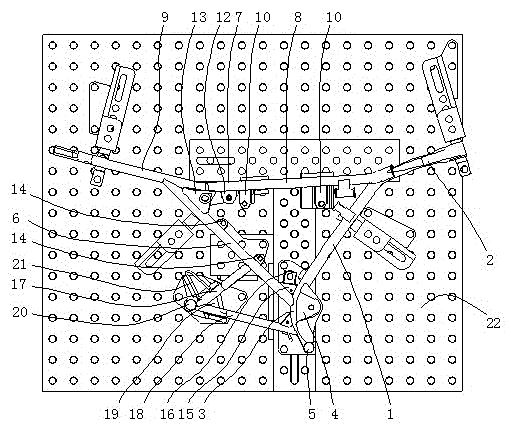

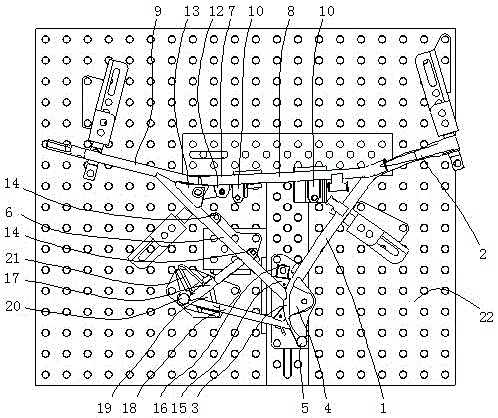

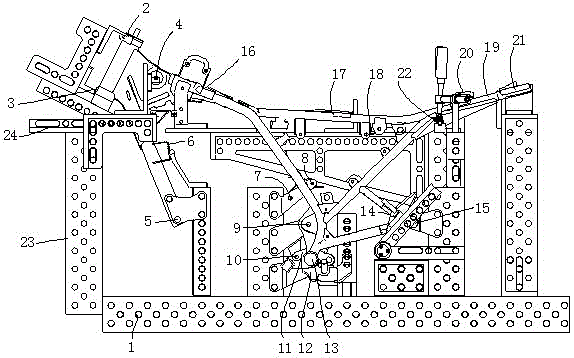

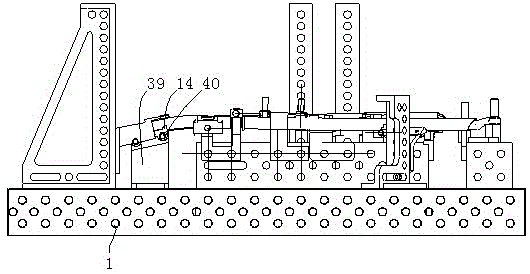

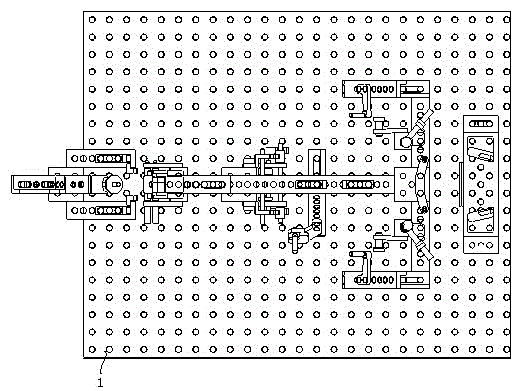

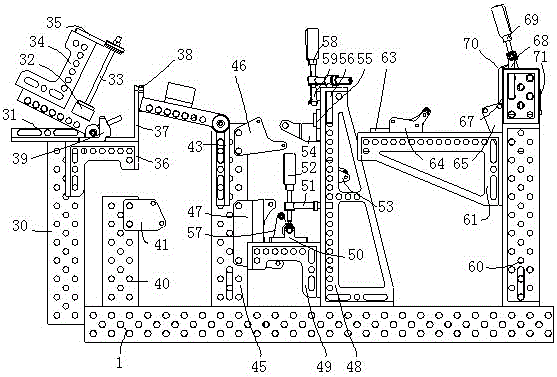

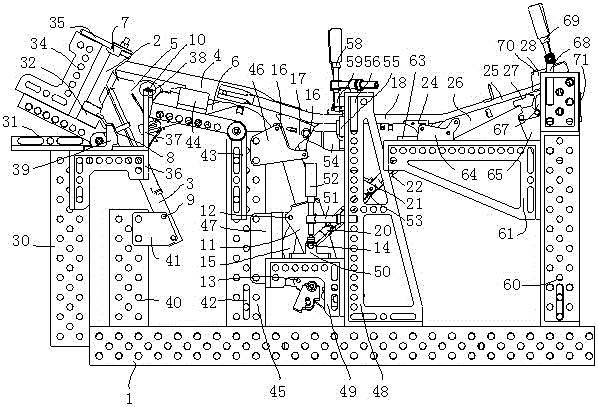

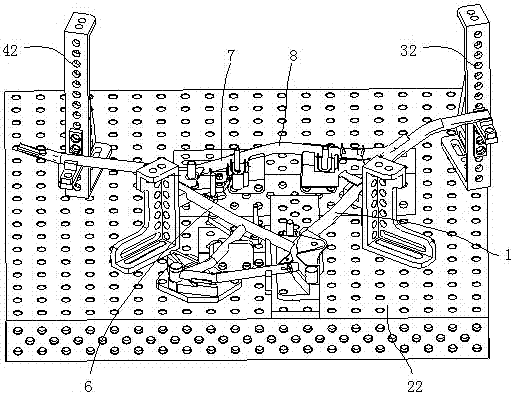

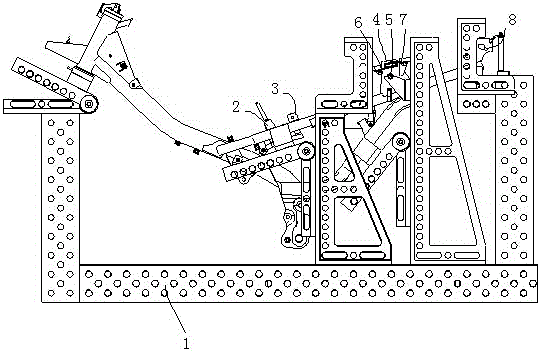

Frame welding clamp for motorcycle sample

InactiveCN105081650AConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

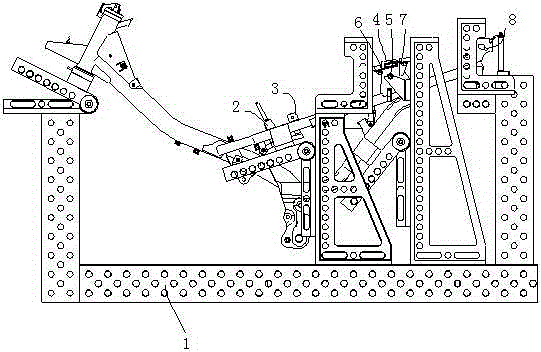

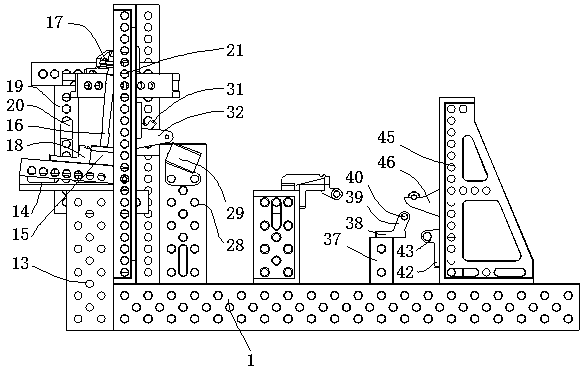

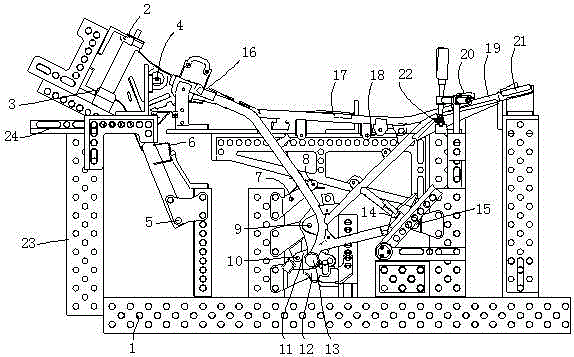

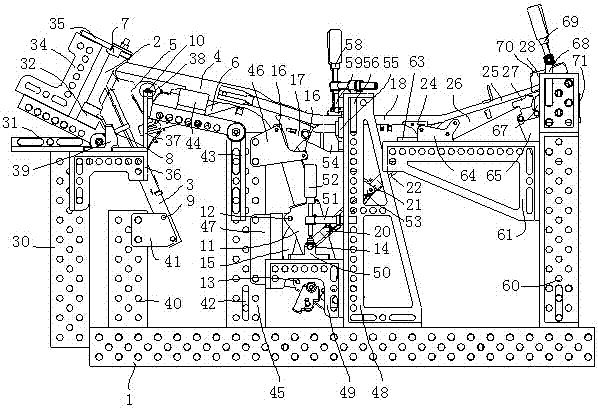

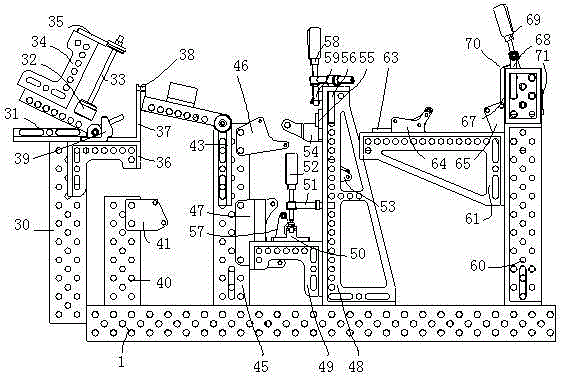

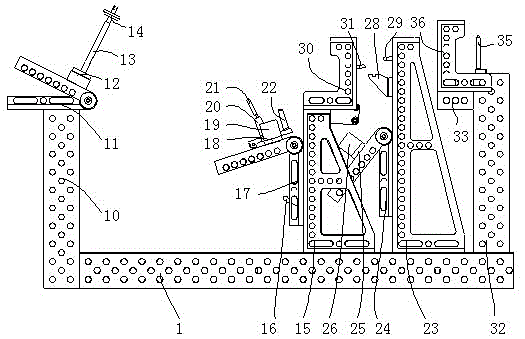

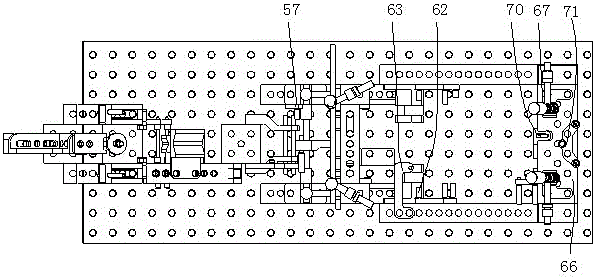

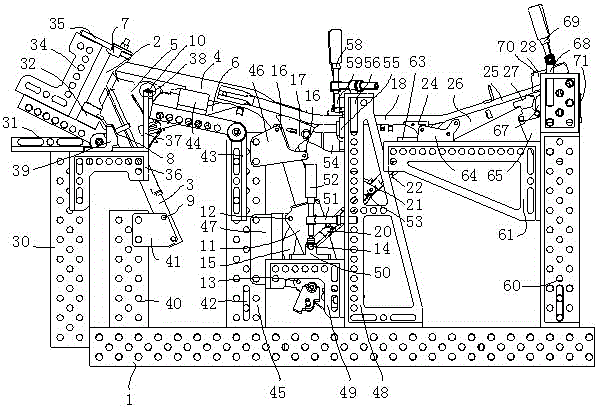

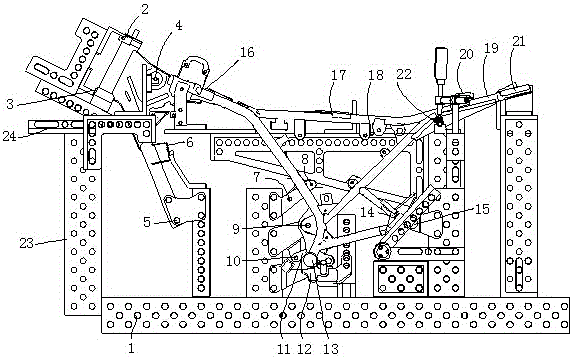

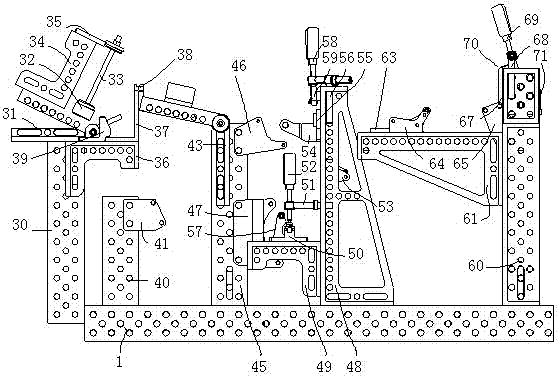

The invention discloses a frame welding clamp for a motorcycle sample. The frame welding clamp is characterized by comprising a three-dimensional installation platform, a motorcycle head pipe assembly combination positioning and welding clamp structure, a frame half-body combination lower portion positioning and welding clamp structure and a frame half-body combination upper portion positioning and welding clamp structure, wherein a plurality of installation holes which are arranged in an array manner at fixed internals are formed in the upper surface and the peripheral side surfaces of the three-dimensional installation platform, and the motorcycle head pipe assembly combination positioning and welding clamp structure, the frame half-body combination lower portion positioning and welding clamp structure and the frame half-body combination upper portion positioning and welding clamp structure are arranged on the three-dimensional installation platform. The frame welding clamp can simplify the welding and assembling procedures and has the beneficial effects of being easy to operate, low in cost, capable of facilitating testing adjustment of the motorcycle sample and the like.

Owner:力帆科技(集团)股份有限公司

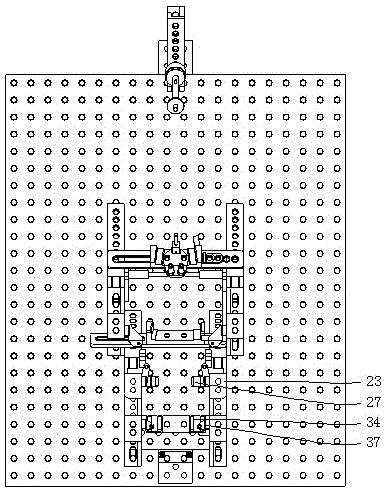

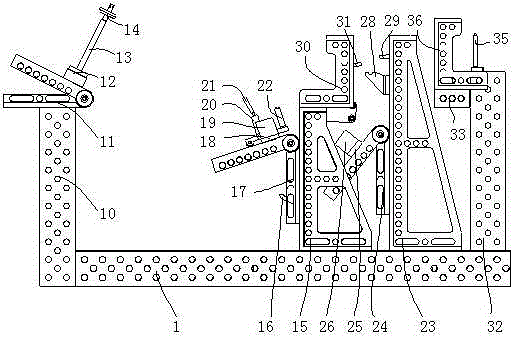

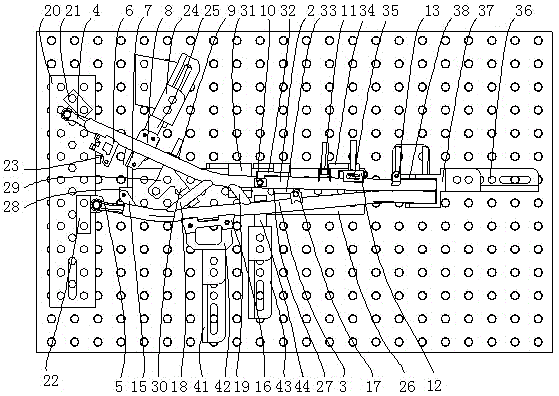

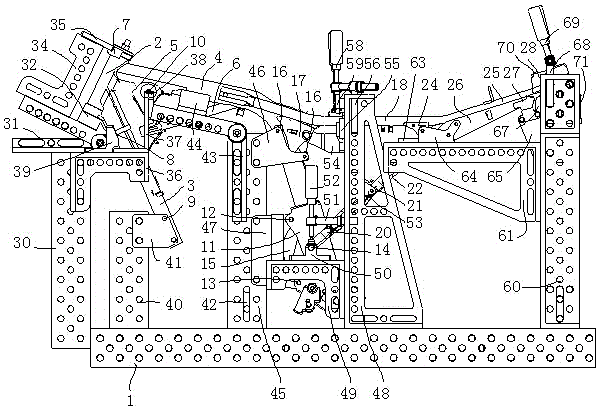

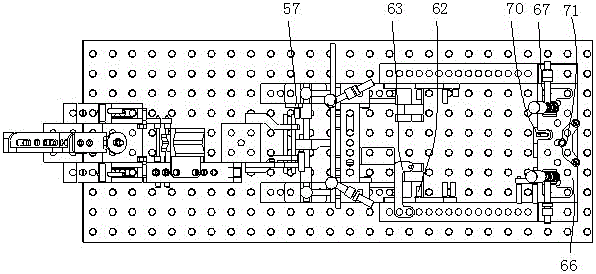

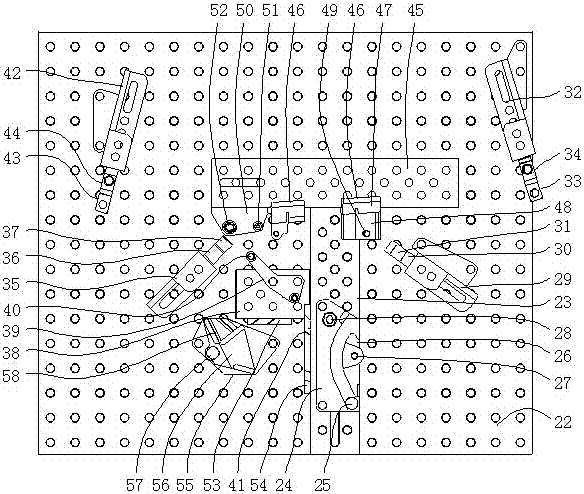

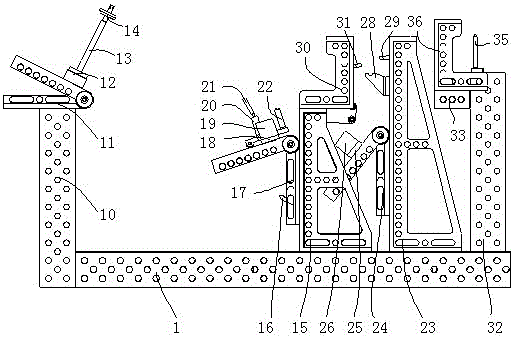

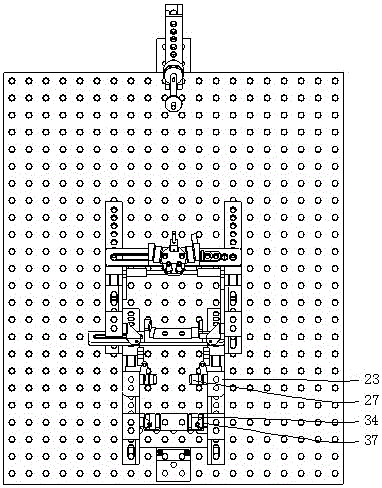

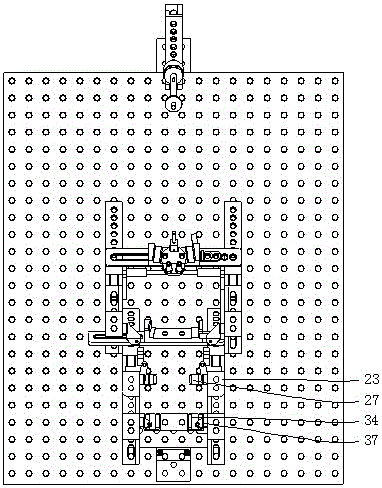

Welding clamp for half frame assembly used for motorcycle sample

InactiveCN105081648AConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesPipe welding

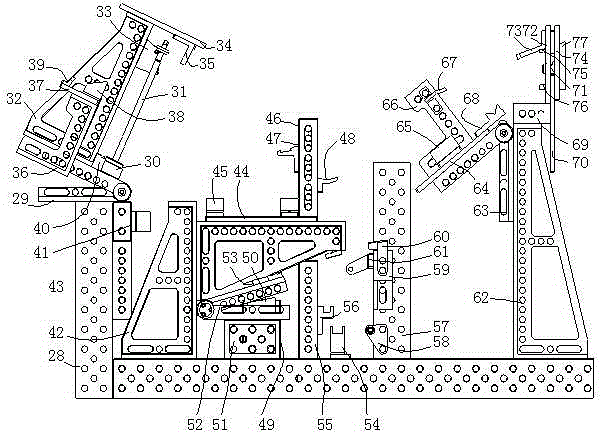

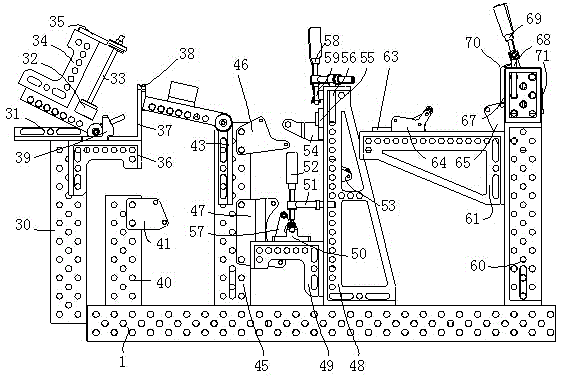

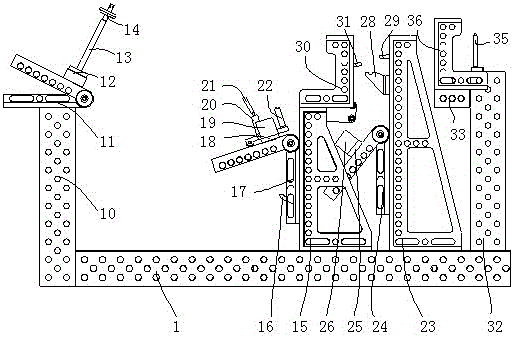

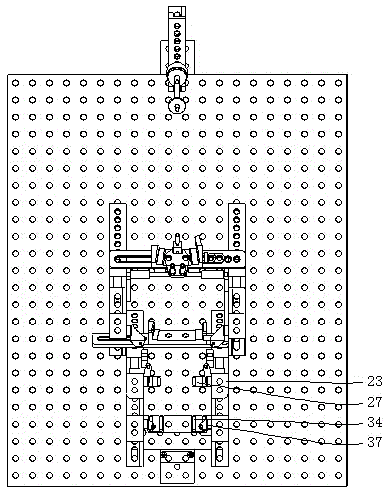

The invention discloses a welding clamp for a half frame assembly used for a motorcycle sample. The welding clamp is characterized by comprising a three-dimensional installing platform, a front lower pipe welding clamp structure, a rear lower pipe welding clamp structure, an upper pipe welding clamp structure and a pedal installing assembly welding clamp structure, wherein a plurality of installing holes are formed in the upper surface and the peripheral surfaces of the three-dimensional installing platform in an array mode at equal intervals, and the front lower pipe welding clamp structure, the rear lower pipe welding clamp structure, the upper pipe welding clamp structure and the pedal installing assembly welding clamp structure are arranged on the three-dimensional installing platform. By means of the welding clamp, the welding and assembling working procedures can be simplified, and the welding clamp has the advantages that the operation is simple, the cost is low, and the trial-manufacture and adjustment of the motorcycle sample can be facilitated.

Owner:力帆科技(集团)股份有限公司

Frame semi-body assembly machining method for motorcycle sample

InactiveCN105108414AConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a frame semi-body assembly machining method for a motorcycle sample. The machining method comprises the following steps: first separately finishing the machining of a front down tube, a front down tube horizontal connecting sleeve, a flat fork shaft installing plate, a lower inclined angle reinforcing block and a reinforcing block accumulator installing lug; finishing the machining of a rear down tube and two down tube covering parts; finishing the machining of a top tube, two top tube accumulator installing lugs, a top tube covering part installing lug and an upper inclined angle reinforcing block; finishing the machining of a pedal upper installing tube, a pedal lower installing tube, a pedal installing tube horizontal connecting sleeve, a rear inclined angle reinforcing block and a rear pedal hook rod; positioning the aforementioned components by a welding fixture, then finishing welding at one time so as to connect all the components and obtaining the frame semi-body assembly for the motorcycle sample. The machining method of the invention can simplify welding and assembling procedures, and is simple to implement and low in cost, and can facilitate the trial-production and adjustment of the motorcycle sample.

Owner:力帆科技(集团)股份有限公司

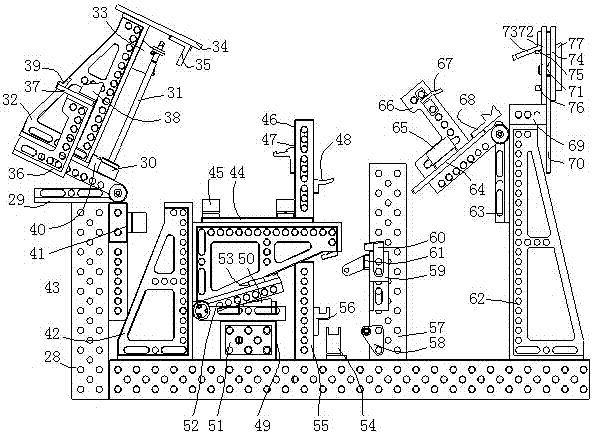

Positioning and welding clamp structure for motorcycle head pipe assembly combination of motorcycle sample

InactiveCN105081651AAchieve positioningAccurate and reliableWelding/cutting auxillary devicesAuxillary welding devicesFuel tank

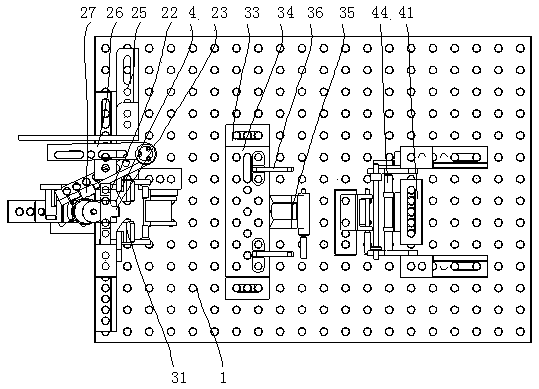

The invention discloses a positioning and welding clamp structure for a motorcycle head pipe assembly combination of a motorcycle sample. The positioning and welding clamp structure is characterized by comprising a motorcycle head pipe positioning assembly used for achieving positioning of a motorcycle head pipe, a direction locking block positioning assembly used for achieving positioning of a direction locking block, a direction limiting block positioning assembly used for achieving positioning of a direction limiting block, an oil tank clamping shaft positioning assembly used for achieving positioning of an oil tank clamping shaft, an engine front suspension installation shaft positioning assembly used for achieving positioning of an engine front suspension installation shaft, and a downward-inclined tube accessory installation hanger positioning assembly used for achieving positioning of a downward-inclined tube accessory installation hanger. The positioning and welding clamp structure can simplify the welding and assembling procedures and has the beneficial effects of being simple in operation, low in cost, capable of facilitating testing adjustment of the motorcycle sample and the like.

Owner:力帆科技(集团)股份有限公司

Machining method of camber beam motorcycle sample frame

InactiveCN105215594AConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameFuel tank

The invention discloses a machining method of a camber beam motorcycle sample frame. The machining method is characterized in that a front half body of the frame is independently machined firstly, independent machining of two rear lower beam pipes and two rear upper beam pipes is finished, and independent machining of an oil tank front support and a seat cushion support is finished; independent machining of a rear damping shaft support lug, a rear damping shaft, an oil tank rear support and a motorcycle body coverage piece support lug is finished; independent machining of a seat cushion lock support and a tail cover support lug is finished; and the components are positioned through a welding clamp, one-time welding is carried out, the components are connected, and the camber beam motorcycle sample frame is obtained. According to the machining method, the welding assembling procedure can be simplified, and the machining method has the beneficial effects that operation is easy, cost is low, and trial-manufacture adjustment of a camber beam motorcycle sample can be facilitated.

Owner:力帆科技(集团)股份有限公司

Method for processing rear segment structure of sample scooter frame

InactiveCN105290679AConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a method for processing the rear segment structure of a sample scooter frame. The method is characterized by comprising the following steps: a welding fixture capable of clamping and positioning all components of the rear segment structure of the scooter frame is obtained; a trunk rear-support positioning component capable of realizing pressing-down type locking positioning for a trunk rear-support is designed in the welding fixture, and the pressing force of the positioning component for the trunk rear-support can tightly press the rear segment of an upper beam pipe; a seat cushion rear-support positioning component capable of realizing pressing-down type locking positioning for a seat cushion rear-support is designed in the welding fixture, and the pressing force of the positioning component for the seat cushion rear-support can tightly press a tail pipe; after all the components of the rear segment structure of the scooter frame are clamped and fixed, a welding gun is adopted to complete the fixed welding among the clamped components in one time, and the processing is finished. The method can simplify the welding assembly procedure, has the advantages of being easy to operation and low in cost, and can be convenient for trail-manufacture adjustment of the rear segment of a scooter sample.

Owner:力帆科技(集团)股份有限公司

Striding type sports car sample frame rear half body machining method

InactiveCN105458564AConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesHandrailVehicle frame

The invention discloses a striding type sports car sample frame rear half body machining method. The method is characterized by including the steps that a welding clamp is obtained firstly, a rear upper beam pipe and a rear lower beam pipe are horizontally located overall through the welding clamp, a rear upper beam pipe connector, a rear lower beam pipe connector, a wire joint supporting lug, an upper ballast supporting lug, a lower ballast supporting lug, a side cover supporting lug, a front cushion supporting lug, a rear cushion supporting lug, a front tail cover supporting lug, a middle tail cover supporting lug, a rear tail cover supporting lug, a rear handrail front supporting lug, a rear handrail rear supporting lug, a rear pedal support, a rear beam front connecting pipe and a rear beam rear connecting pipe are located through the welding clamp, and the installation ends of all the components are attached to the corresponding installation positions; and after being located, all the components are welded and fixed through a welding gun at a time, and therefore a striding type sports car frame rear half body structure is obtained. The method has the advantages that the welding and assembling working procedures can be simplified, operation is easy, cost is low, and trail production and adjustment of a striding type sports car sample can be facilitated.

Owner:力帆科技(集团)股份有限公司

Machining method for riding type sports car sample frame

InactiveCN105522289AImprove processing efficiencyAvoid interferenceWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameMachining

The invention discloses a machining method for a riding type sports car sample frame. The machining method is characterized by comprising the steps of firstly, independently machining to obtain two rear half frames; then, finishing the location of all components on the middle section of the frame by using a welding fixture, and disassembling after finishing the fixation and welding of rear upper beam connecting blocks and main beam pipes to avoid generating interference to the located components clamped by the rear upper beam connecting blocks, and then, finishing the clamping and location of all the components at the front section and the rear section of the frame; and next, finishing the welding and fixation among all the located components at one step by using a welding gun, and furthermore finishing the machining of the riding type sports car sample frame. The machining method can be used for simplifying the welding and assembling processes and has the advantages of simplicity in operation, low cost and convenience in trial-production and regulation of a riding type sports car sample.

Owner:力帆科技(集团)股份有限公司

Front half frame body machining method for camber beam vehicle sample

InactiveCN105364366AConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a front half frame body machining method for a camber beam vehicle sample. The front half frame body machining method is characterized in that firstly, a vertical pipe, a directional lock support, a meter housing support, a directional lock block and a radiator grille mounting plate are machined independently; a girder pipe, wind shield supports, a center joint plate front support and center joint plate rear supports are machined independently; an engine suspension mounting plate and a flat fork shaft are machined independently; and all the components are located through a welding clamp, then all the components are connected and welded at a time, and the front half frame body for the camber beam vehicle sample is obtained. By means of the front half frame body machining body, the welding assembly process can be simplified, and the front half frame body machining method has the advantages of being simple in operation, low in cost, capable of trial-producing and adjusting the camber beam vehicle sample conveniently and the like.

Owner:力帆科技(集团)股份有限公司

Method for machining motorcycle frame used for motorcycle sample

InactiveCN105215631AConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a method for machining a motorcycle frame used for a motorcycle sample. The method is characterized by comprising the steps that firstly, independent machining of a motorcycle head tube assembly combination and independent machining of left half motorcycle frame body and right half motorcycle frame body combining are completed; secondly, independent machining of accessory components is completed; and finally, the components are positioned through a welding clamp, then welding is completed at a time, and the motorcycle frame used for the motorcycle sample is obtained by connecting the components. By means of the method, welding assembly procedures can be simplified, and the method has the advantages that the operation is easy, cost is low, and trial-manufacture and adjustment of the motorcycle sample can be facilitated.

Owner:力帆科技(集团)股份有限公司

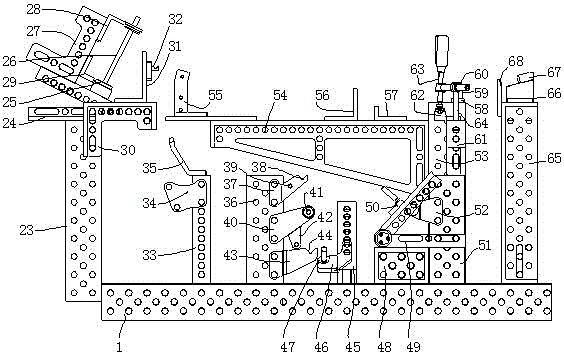

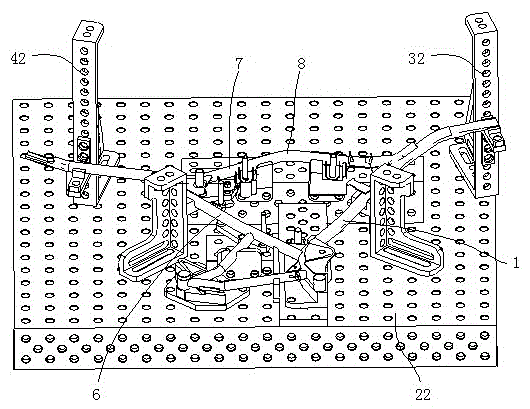

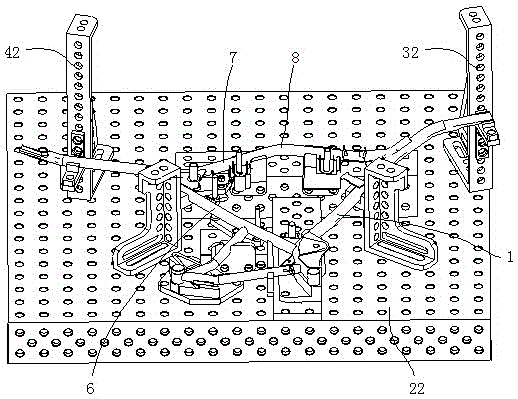

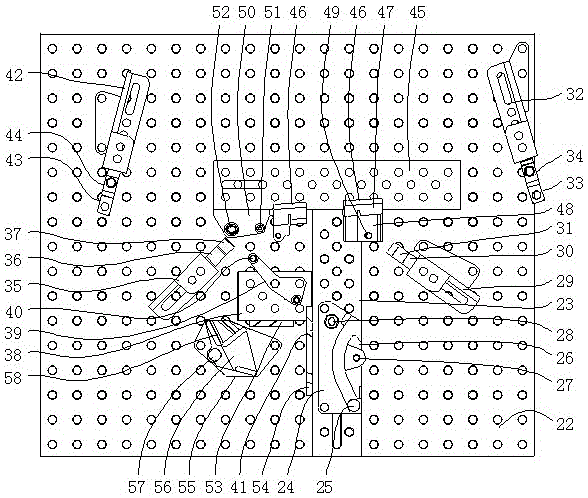

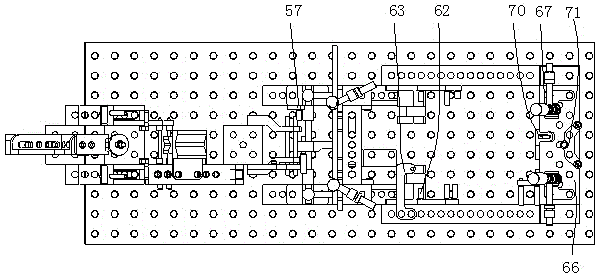

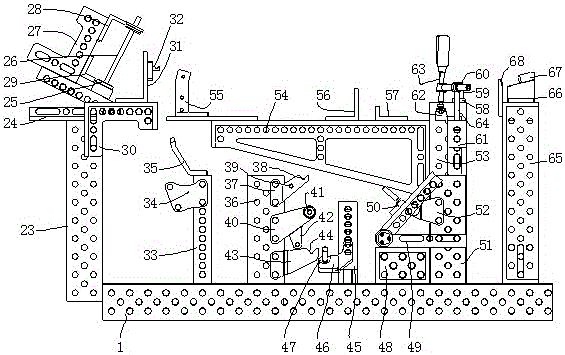

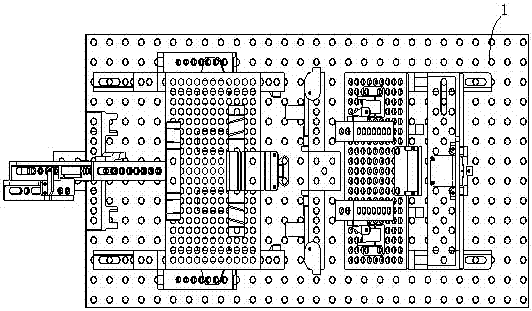

Frame welding clamp for motorcycle sample

InactiveCN105328379AConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

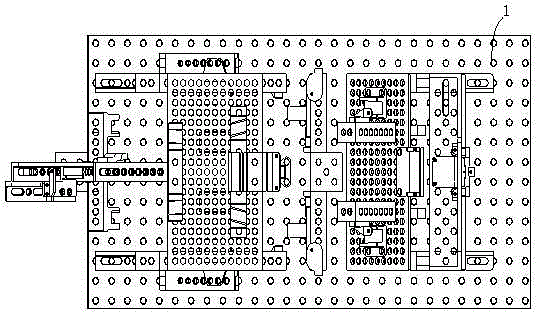

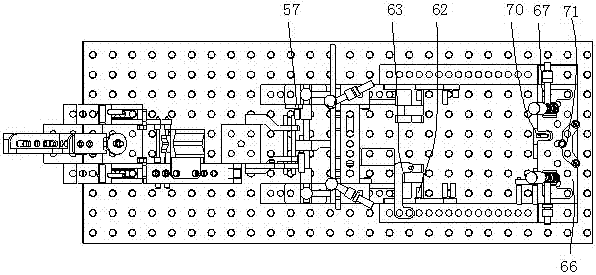

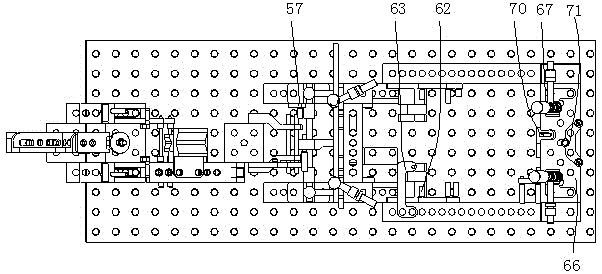

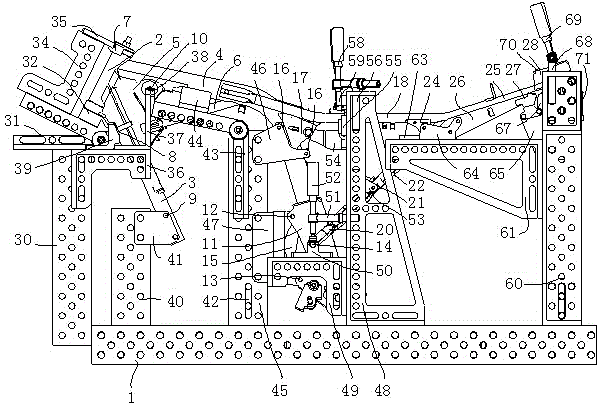

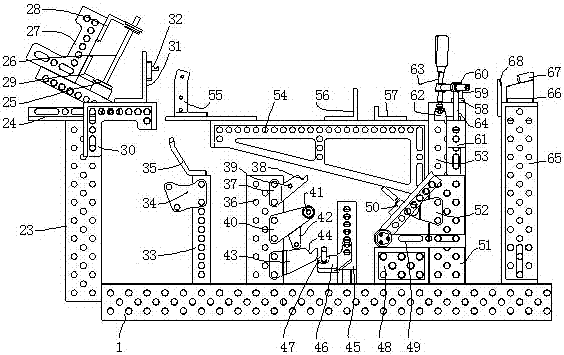

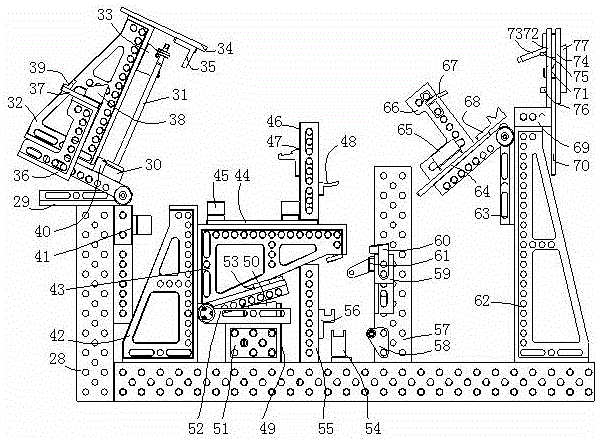

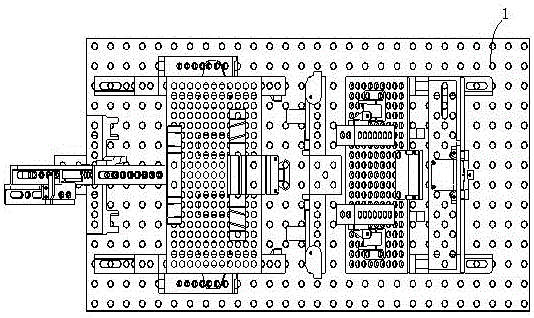

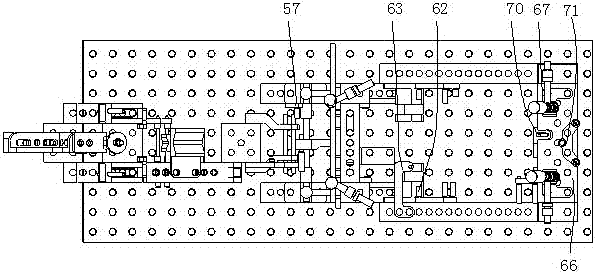

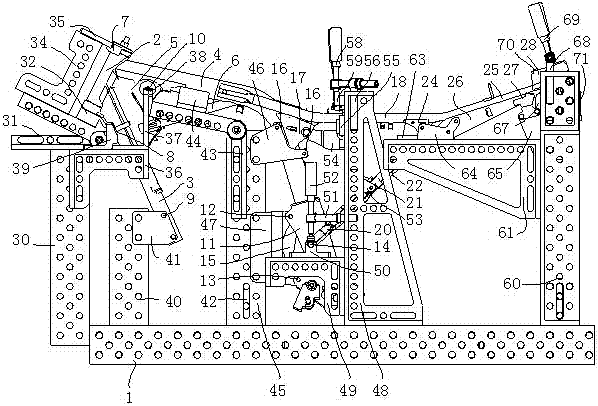

The invention discloses a frame welding clamp for a motorcycle sample. The frame welding clamp is characterized in that the frame welding clamp comprises a three-dimensional mounting platform, a frame front segment locating and welding clamp structure, a frame middle segment locating and welding clamp structure and a frame rear segment locating and welding clamp structure; the upper surface and the peripheral surface of the three-dimensional mounting platform are each provided with a plurality of mounting holes at a fixed distance in an array manner; and the frame front segment locating and welding clamp structure, the frame middle segment locating and welding clamp structure and the frame rear segment locating and welding clamp structure are arranged on the three-dimensional mounting platform. According to the frame welding clamp, welding and assembling procedures can be simplified, and the frame welding clamp has the beneficial effects of being easy to operate, low in cost, capable of facilitating trial-manufacturing and adjusting of the motorcycle sample and the like.

Owner:力帆科技(集团)股份有限公司

Frame half body assembly lower portion positioned welding clamp structure for motorcycle sample

InactiveCN105081652AConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a frame half body assembly lower portion positioned welding clamp structure for a motorcycle sample. The frame half body assembly lower portion positioned welding clamp structure for the motorcycle sample is characterized in that the structure comprises an engine rear upper suspension mounting shaft and front lower tube reinforcing connection shaft positioning component for achieving positioning of an engine rear upper suspension mounting shaft and a front lower tube reinforcing connection shaft at the same time, a bottom fork shaft and engine rear lower suspension mounting shaft positioning component for achieving positioning of a bottom fork shaft and an engine rear lower suspension mounting shaft at the same time, a front lower tube horizontal connection shaft positioning component for achieving positioning of a front lower tube horizontal connection shaft, a side support mounting plate positioning component for achieving positioning of a side support mounting plate, a rear pedal lug positioning component for achieving positioning of a rear pedal lug and a pedal mounting tube horizontal connection shaft positioning component for achieving positioning of a pedal mounting tube horizontal connection shaft. The frame half body assembly lower portion positioned welding clamp structure has the advantages of being capable of simplifying a welding assembly process, easy to operate, low in cost, capable of facilitating trial production and adjustment of the motorcycle sample and the like.

Owner:力帆科技(集团)股份有限公司

A processing method for the structure of the middle section of the test frame of a rider bike

InactiveCN105328380BConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameAir filter

The invention discloses a method for machining a frame middle segment structure of a motorcycle sample. The method comprises the steps that a welding clamp is firstly adopted for locating an engine suspension mounting rack, an engine rear upper suspension shaft, an engine rear lower suspension shaft, a flat fork shaft, a sided cover lock supporting lug, a storage battery supporting lug, a front reinforcement block, an upper pipe front segment, a lower pipe front segment and a side cover lower supporting lug; then a welding gun is adopted for completing welding and fixing of the components at a time, after welding is completed, a compressing mechanism of the upper pipe front segment is horizontally rotated outward to avoid interference, then an air filter supporting lug locating plate used for achieving locating of an air filter support is mounted, the front side face of the air filter support is located through an air filter support locating plate, and then welding and fixing of the air filter support are completed. According to the method, welding and assembling procedures can be simplified, and the method has the beneficial effects that operation is easy, cost is low, and trial-manufacturing and adjusting of the middle segment of the motorcycle sample can be facilitated.

Owner:力帆科技(集团)股份有限公司

Frame Welding Fixture for Knight Car Sample

InactiveCN105328379BConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a frame welding clamp for a motorcycle sample. The frame welding clamp is characterized in that the frame welding clamp comprises a three-dimensional mounting platform, a frame front segment locating and welding clamp structure, a frame middle segment locating and welding clamp structure and a frame rear segment locating and welding clamp structure; the upper surface and the peripheral surface of the three-dimensional mounting platform are each provided with a plurality of mounting holes at a fixed distance in an array manner; and the frame front segment locating and welding clamp structure, the frame middle segment locating and welding clamp structure and the frame rear segment locating and welding clamp structure are arranged on the three-dimensional mounting platform. According to the frame welding clamp, welding and assembling procedures can be simplified, and the frame welding clamp has the beneficial effects of being easy to operate, low in cost, capable of facilitating trial-manufacturing and adjusting of the motorcycle sample and the like.

Owner:力帆科技(集团)股份有限公司

A kind of frame processing method for curved beam car sample

InactiveCN105215594BConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameFuel tank

The invention discloses a machining method of a camber beam motorcycle sample frame. The machining method is characterized in that a front half body of the frame is independently machined firstly, independent machining of two rear lower beam pipes and two rear upper beam pipes is finished, and independent machining of an oil tank front support and a seat cushion support is finished; independent machining of a rear damping shaft support lug, a rear damping shaft, an oil tank rear support and a motorcycle body coverage piece support lug is finished; independent machining of a seat cushion lock support and a tail cover support lug is finished; and the components are positioned through a welding clamp, one-time welding is carried out, the components are connected, and the camber beam motorcycle sample frame is obtained. According to the machining method, the welding assembling procedure can be simplified, and the machining method has the beneficial effects that operation is easy, cost is low, and trial-manufacture adjustment of a camber beam motorcycle sample can be facilitated.

Owner:力帆科技(集团)股份有限公司

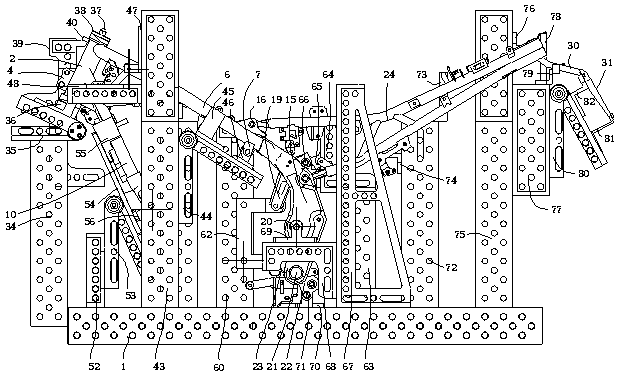

Positioning and welding clamp structure of front part section of riding type motorcycle sample frame

InactiveCN105328381AConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameFuel tank

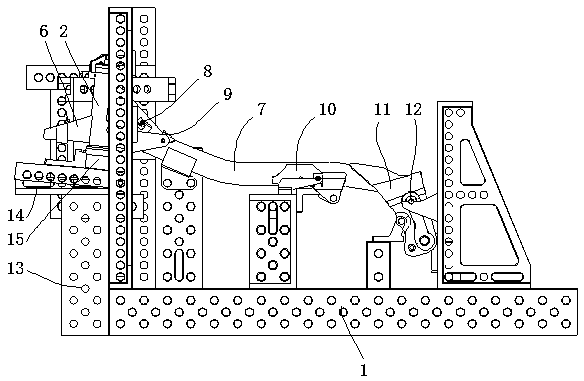

The invention discloses a positioning and welding clamp structure of a front part section of a riding type motorcycle sample frame. The positioning and welding clamp structure is characterized by comprising a three-dimensional installing platform, a plurality of installing holes arranged according to the fixed interval in an array manner are formed in the upper surface and the peripheral side surface of the three-dimensional installing platform, the positioning and welding clamp structure of the riding type motorcycle sample frame further comprises a motorcycle head pipe positioning assembly used for positioning a motorcycle head pipe, a direction limiting block positioning assembly used for positioning a direction limiting block, a motorcycle head pipe connecting plate and oil tank installing shaft positioning assembly used for positioning a motorcycle head pipe connecting plate and an oil tank installing shaft, a radiator support lug positioning assembly used for achieving positioning of a radiator support lug, a front inclined pipe and engine front suspension shaft positioning assembly used for positioning a front inclined pipe and an engine front suspension shaft and a main beam pipe front part section and connecting pipe positioning assembly used for sequentially positioning the main beam pipe front part section and a connecting pipe. The welding and assembling procedure can be simplified, and the front part section positioning and welding clamp structure has the beneficial effects that operation is simple, cost is low, and trial production and adjustment of the sample front part section of a riding type motorcycle can be conveniently achieved.

Owner:力帆科技(集团)股份有限公司

A method for combined processing of frame halves for riding bicycle samples

InactiveCN105108414BConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a frame semi-body assembly machining method for a motorcycle sample. The machining method comprises the following steps: first separately finishing the machining of a front down tube, a front down tube horizontal connecting sleeve, a flat fork shaft installing plate, a lower inclined angle reinforcing block and a reinforcing block accumulator installing lug; finishing the machining of a rear down tube and two down tube covering parts; finishing the machining of a top tube, two top tube accumulator installing lugs, a top tube covering part installing lug and an upper inclined angle reinforcing block; finishing the machining of a pedal upper installing tube, a pedal lower installing tube, a pedal installing tube horizontal connecting sleeve, a rear inclined angle reinforcing block and a rear pedal hook rod; positioning the aforementioned components by a welding fixture, then finishing welding at one time so as to connect all the components and obtaining the frame semi-body assembly for the motorcycle sample. The machining method of the invention can simplify welding and assembling procedures, and is simple to implement and low in cost, and can facilitate the trial-production and adjustment of the motorcycle sample.

Owner:力帆科技(集团)股份有限公司

Frame half combined welding fixture for riding bicycle samples

InactiveCN105081648BConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a welding clamp for a half frame assembly used for a motorcycle sample. The welding clamp is characterized by comprising a three-dimensional installing platform, a front lower pipe welding clamp structure, a rear lower pipe welding clamp structure, an upper pipe welding clamp structure and a pedal installing assembly welding clamp structure, wherein a plurality of installing holes are formed in the upper surface and the peripheral surfaces of the three-dimensional installing platform in an array mode at equal intervals, and the front lower pipe welding clamp structure, the rear lower pipe welding clamp structure, the upper pipe welding clamp structure and the pedal installing assembly welding clamp structure are arranged on the three-dimensional installing platform. By means of the welding clamp, the welding and assembling working procedures can be simplified, and the welding clamp has the advantages that the operation is simple, the cost is low, and the trial-manufacture and adjustment of the motorcycle sample can be facilitated.

Owner:力帆科技(集团)股份有限公司

Frame rear beam tube front positioning welding clamp structure used for cub-type motorcycle sample

InactiveCN105108421AConvenient trial production adjustmentSimple structureWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameFuel tank

The invention discloses a frame rear beam tube front positioning welding clamp structure used for a cub-type motorcycle sample. The frame rear beam tube front positioning welding clamp structure is characterized by comprising a rear upper beam tube front positioning assembly, an oil tank front support positioning assembly, a seat cushion support positioning assembly and a rear lower beam tube front positioning assembly. The rear upper beam tube front positioning assembly is used for positioning the front of a rear upper beam tube, the oil tank front support positioning assembly is used for positioning an oil tank front support, the seat cushion support positioning assembly is used for positioning a seat cushion support, and the rear lower beam tube front positioning assembly is used for positioning the front of a rear beam tube. The frame rear beam tube front positioning welding clamp structure is simple, reliable in positioning and capable of simplifying the welding assembly process and has the advantages of being easy to operate, low in cost, capable of facilitating trial-manufacture adjusting of the cub-type motorcycle sample and the like.

Owner:力帆科技(集团)股份有限公司

Fixture structure for positional welding of the rear part of the rear beam tube of the frame for the sample of the curved beam vehicle

InactiveCN105149845BConvenient trial production adjustmentSimple structureWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameBeam tube

Owner:力帆科技(集团)股份有限公司

Frame Welding Fixture for Bending Beam Car Sample

InactiveCN105108420BConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameBeam tube

The invention discloses a frame welding clamp used for a cub-type motorcycle sample. The frame welding clamp is characterized by comprising a three-dimensional installing platform, a frame front half body positioning clamp structure, a rear beam tube front positioning welding clamp structure, a rear beam tube rear positioning welding clamp structure and a rear beam tube tail positioning welding clamp structure, wherein multiple installing holes are arrayed at a fixed distance in the upper surface and periphery side surface of the three-dimensional installing platform, and the frame front half body positioning clamp structure, the rear beam tube front positioning welding clamp structure, the rear beam tube rear positioning welding clamp structure and the rear beam tube tail positioning welding clamp structure are arranged on the three-dimensional installing platform. The welding assembly process can be simplified, and the frame welding clamp has the advantages of being easy to operate, low in cost, capable of facilitating trial-manufacture adjustment of the cub-type motorcycle sample and the like.

Owner:力帆科技(集团)股份有限公司

Combination positioning welding fixture structure of head tube assembly for riding bike sample

InactiveCN105081651BAchieve positioningAccurate and reliableWelding/cutting auxillary devicesAuxillary welding devicesFuel tankHeadstock

The invention discloses a positioning and welding clamp structure for a motorcycle head pipe assembly combination of a motorcycle sample. The positioning and welding clamp structure is characterized by comprising a motorcycle head pipe positioning assembly used for achieving positioning of a motorcycle head pipe, a direction locking block positioning assembly used for achieving positioning of a direction locking block, a direction limiting block positioning assembly used for achieving positioning of a direction limiting block, an oil tank clamping shaft positioning assembly used for achieving positioning of an oil tank clamping shaft, an engine front suspension installation shaft positioning assembly used for achieving positioning of an engine front suspension installation shaft, and a downward-inclined tube accessory installation hanger positioning assembly used for achieving positioning of a downward-inclined tube accessory installation hanger. The positioning and welding clamp structure can simplify the welding and assembling procedures and has the beneficial effects of being simple in operation, low in cost, capable of facilitating testing adjustment of the motorcycle sample and the like.

Owner:力帆科技(集团)股份有限公司

A processing method for the structure of the rear section of the sample frame of a rider bike

InactiveCN105382456BConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameMachining

The invention discloses a machining method of a motorcycle sample frame rear-segment structure. The machining method is characterized in that welding jigs are adopted to locate a lower pipe rear portion segment, an electric device supporting lug, a side cover rear supporting lug, an upper pipe tail segment, a rear reinforcing plate, a seat cushion lock support and a tail cover support; the components mentioned above are welded and fixed through a weld gun, and an upper pipe tail segment pressing mechanism for pressing the upper pipe tail segment is arranged in an upper pipe tail segment locating structure and can be horizontally rotated; and after welding is finished, the upper pipe tail segment pressing mechanism is horizontally rotated outwards to avoid interference, a seat cushion rear support is mounted and located and then is welded and fixed. The machining method has the advantages that the welding assembly process can be simplified, operation is simple, cost is low and trial-manufacturing and adjusting of the motorcycle sample frame rear-segment structure can be facilitated.

Owner:力帆科技(集团)股份有限公司

Positioning welding fixture structure for the front part of the rear beam tube of the frame for the sample of the bent beam vehicle

InactiveCN105108421BConvenient trial production adjustmentSimple structureWelding/cutting auxillary devicesAuxillary welding devicesFuel tankBack rests

The invention discloses a frame rear beam tube front positioning welding clamp structure used for a cub-type motorcycle sample. The frame rear beam tube front positioning welding clamp structure is characterized by comprising a rear upper beam tube front positioning assembly, an oil tank front support positioning assembly, a seat cushion support positioning assembly and a rear lower beam tube front positioning assembly. The rear upper beam tube front positioning assembly is used for positioning the front of a rear upper beam tube, the oil tank front support positioning assembly is used for positioning an oil tank front support, the seat cushion support positioning assembly is used for positioning a seat cushion support, and the rear lower beam tube front positioning assembly is used for positioning the front of a rear beam tube. The frame rear beam tube front positioning welding clamp structure is simple, reliable in positioning and capable of simplifying the welding assembly process and has the advantages of being easy to operate, low in cost, capable of facilitating trial-manufacture adjusting of the cub-type motorcycle sample and the like.

Owner:力帆科技(集团)股份有限公司

A method for processing the structure of the front section of the scooter sample frame

InactiveCN105382435BConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a machining method for the structure of a front section of a sample frame of a scooter. The machining method is characterized din that a welding clamp is used for completing clamping and fixing among a headstock pipe, the front end of a lower beam pipe, an ignition switch lock support, a meter housing support and a direction lock block; a welding gun is used for welding and fixing the parts; a positioning assembly used for clamping and positioning the ignition switch lock support and the meter housing support is demounted so as to prevent interference; a positioning assembly used for clamping and positioning a radiator grille installation pipe and a radiator grille installation supporting lug is well installed in the welding clamp so that the radiator grille installation pipe and the radiator grille installation supporting lug can be clamped and positioned; and then the welding gun is used for completing welding between the radiator grille installation pipe and the headstock pipe and welding between the radiator grille installation pipe and the radiator grille installation supporting lug. The machining method has the advantages that welding and assembling processes can be simplified, operation is simple, cost is low, and trial-manufacture and adjusting of the front section of the sample frame of the scooter can be conducted conveniently.

Owner:力帆科技(集团)股份有限公司

Fixture structure for positioning and welding the upper part of the frame half-body combination for the knight car sample

InactiveCN105081653BConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameBody composition

Owner:力帆科技(集团)股份有限公司

A method of processing a frame for a sample of a knight's vehicle

InactiveCN105215631BConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameLeft half

Owner:力帆科技(集团)股份有限公司

A method for processing the structure of the rear section of the scooter sample frame

InactiveCN105290679BConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a method for processing the rear segment structure of a sample scooter frame. The method is characterized by comprising the following steps: a welding fixture capable of clamping and positioning all components of the rear segment structure of the scooter frame is obtained; a trunk rear-support positioning component capable of realizing pressing-down type locking positioning for a trunk rear-support is designed in the welding fixture, and the pressing force of the positioning component for the trunk rear-support can tightly press the rear segment of an upper beam pipe; a seat cushion rear-support positioning component capable of realizing pressing-down type locking positioning for a seat cushion rear-support is designed in the welding fixture, and the pressing force of the positioning component for the seat cushion rear-support can tightly press a tail pipe; after all the components of the rear segment structure of the scooter frame are clamped and fixed, a welding gun is adopted to complete the fixed welding among the clamped components in one time, and the processing is finished. The method can simplify the welding assembly procedure, has the advantages of being easy to operation and low in cost, and can be convenient for trail-manufacture adjustment of the rear segment of a scooter sample.

Owner:力帆科技(集团)股份有限公司

The positioning welding fixture structure of the front section of the knight car sample frame

InactiveCN105328381BConvenient trial production adjustmentSimplify solder assembly processWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameFuel tank

The invention discloses a positioning and welding clamp structure of a front part section of a riding type motorcycle sample frame. The positioning and welding clamp structure is characterized by comprising a three-dimensional installing platform, a plurality of installing holes arranged according to the fixed interval in an array manner are formed in the upper surface and the peripheral side surface of the three-dimensional installing platform, the positioning and welding clamp structure of the riding type motorcycle sample frame further comprises a motorcycle head pipe positioning assembly used for positioning a motorcycle head pipe, a direction limiting block positioning assembly used for positioning a direction limiting block, a motorcycle head pipe connecting plate and oil tank installing shaft positioning assembly used for positioning a motorcycle head pipe connecting plate and an oil tank installing shaft, a radiator support lug positioning assembly used for achieving positioning of a radiator support lug, a front inclined pipe and engine front suspension shaft positioning assembly used for positioning a front inclined pipe and an engine front suspension shaft and a main beam pipe front part section and connecting pipe positioning assembly used for sequentially positioning the main beam pipe front part section and a connecting pipe. The welding and assembling procedure can be simplified, and the front part section positioning and welding clamp structure has the beneficial effects that operation is simple, cost is low, and trial production and adjustment of the sample front part section of a riding type motorcycle can be conveniently achieved.

Owner:力帆科技(集团)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com