Front half frame body machining method for camber beam vehicle sample

A technology for a sample frame and a processing method, which is applied to metal processing equipment, manufacturing tools, auxiliary devices, etc., and can solve problems such as numerous procedures, high cost, and complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

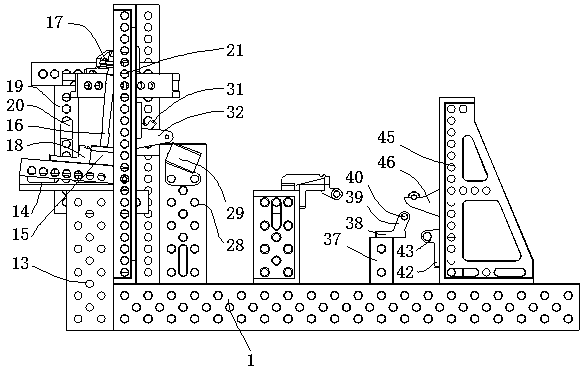

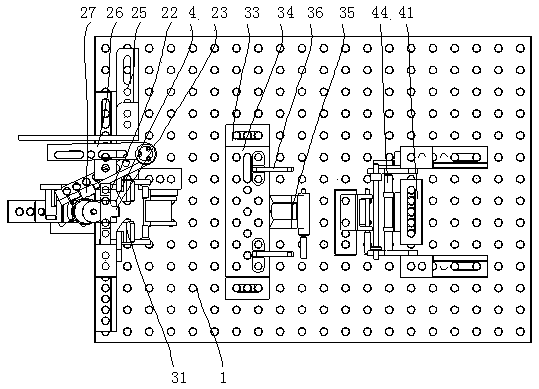

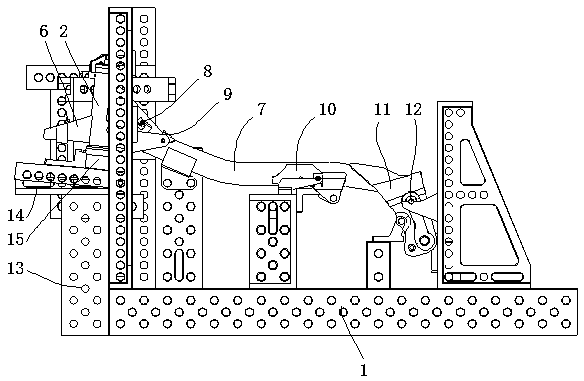

[0035] Optimum implementation mode: a method for processing the front body of a frame for a curved beam vehicle sample, the main point of which is to first complete the processing of the standpipe, the direction lock bracket, the instrument case bracket, the direction lock block and the front cover mounting plate; Separate processing of the main beam tube, windshield bracket, front bracket of the center seam plate and rear bracket of the center seam plate; complete the separate processing of the engine suspension mounting plate and the flat fork shaft; then use the welding fixture to position the above components, and then complete the welding at one time. The components are connected to obtain the front half body of the frame for the curved beam vehicle sample.

[0036] When the method is implemented, a welding jig is obtained first, and then each component is positioned using the welding jig, and then welding is performed. The welding fixture such as Figure 1-4 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com