Machining method for riding type sports car sample frame

A processing method and frame technology, applied in metal processing, metal processing equipment, vehicle parts, etc., can solve the problems of complex operation, numerous procedures, increase cost, etc., and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

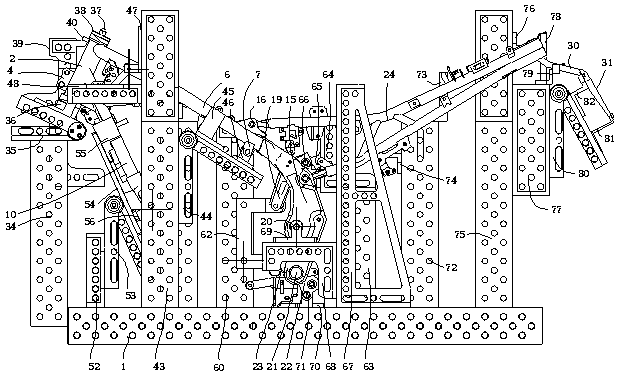

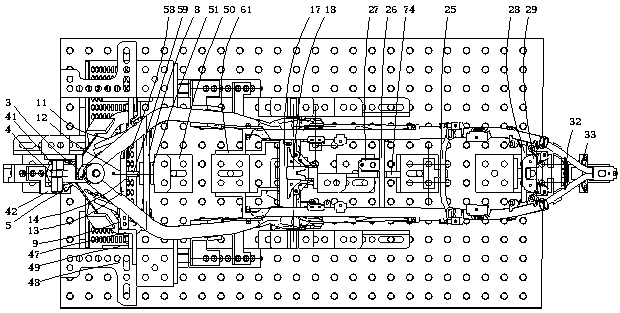

[0053] Optimum implementation mode: when this method is implemented, first obtain a kind of such as Figure 1-2 The welding jig for the frame of the riding sports car sample is shown, and then the welding process is performed after the welding jig is completed. The welding jig includes a three-dimensional installation platform 1 with several installation holes arranged in a fixed-space array on the upper surface and the peripheral surface, and a positioning welding fixture structure for the front section of the vehicle frame and a positioning welding fixture for the middle section of the vehicle frame arranged on the three-dimensional installation platform. The welding jig structure and the positioning welding jig structure of the rear section of the frame; Middle section of main beam tube 6, fuel tank lug 7, main beam horizontal tube 8, oil pump bracket 9, front lower beam tube 10, front beam horizontal connecting tube 11, water cooler bracket 12, engine front suspension hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com