Striding type sports car sample frame rear half body machining method

A processing method and sports car technology, applied in the direction of metal processing equipment, manufacturing tools, auxiliary devices, etc., can solve problems such as numerous processes, high cost, and complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

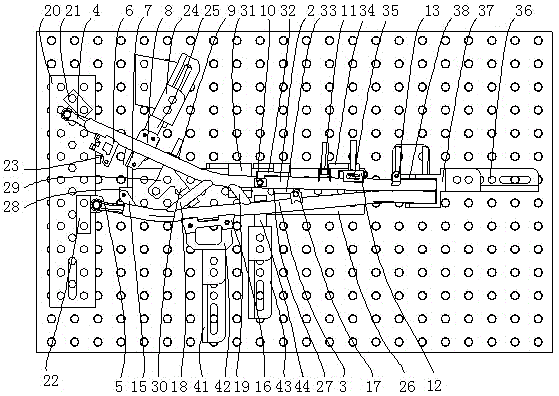

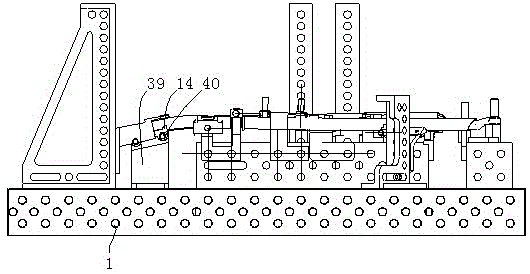

[0043] The optimal implementation mode: a method for processing the rear half of the frame of a riding sports car sample. This method first obtains the following Figure 1-2 The welding fixture for the rear half body of the riding sports car frame of the structure shown, and then rely on the jig to realize the positioning of the components of the rear half body of the riding sports car frame, and then use the welding torch for one-time welding processing.

[0044] Specifically, the welding fixture such as Figure 1-2 As shown, it includes a three-dimensional installation platform 1 with several installation holes arranged in a fixed-space array on the upper surface and the peripheral side surface, and a rear upper beam tube connector positioning assembly and a rear lower beam tube connector set on the three-dimensional installation platform 1. to the tail assembly, the positioning assembly for the middle section of the rear upper beam tube, the positioning assembly for the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com