Stainless steel tube outer diameter polishing device

A technology of polishing device and stainless steel tube, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding heads, etc., can solve the problems of reducing efficiency, reducing work efficiency, and unfavorable full use of abrasives, so as to achieve convenient operation and improve work efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

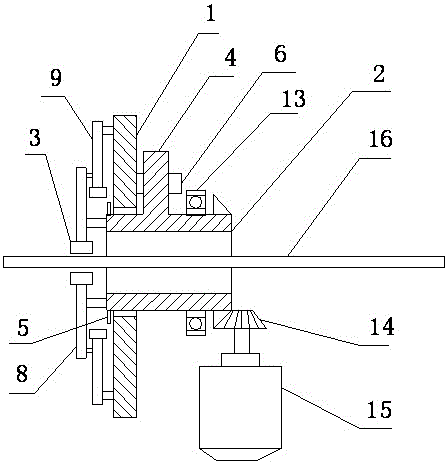

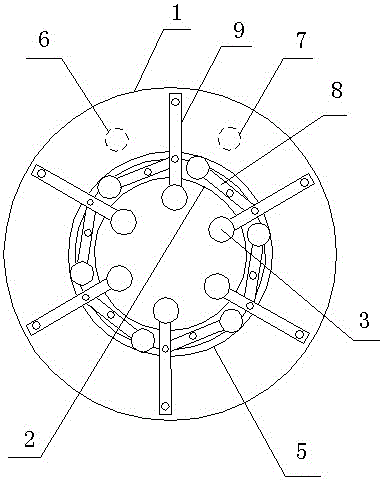

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a stainless steel tube outer diameter polishing device includes a turntable 1, a sleeve 2, and a polishing grinding head 3. The casing 2 is a steel pipe, and a stopper 4 is fixed on the casing 2. The center hole of the turntable 1 is rotatably set on the shaft at the front end of the stopper 4. The end of the casing 2 is provided with a retaining ring 5 , The block 4 and the retaining ring 5 block the turntable 1 to prevent it from moving along the casing. The turntables 1 on both sides of the stopper 4 are respectively provided with limit posts, that is, a left limit post 6 and a right limit post 7 . The limit column restricts the rotation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com