Sorbent packaging

一种包装袋、吸附剂的技术,应用在吸附剂的包装袋领域,能够解决积累、污染、产品不能用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

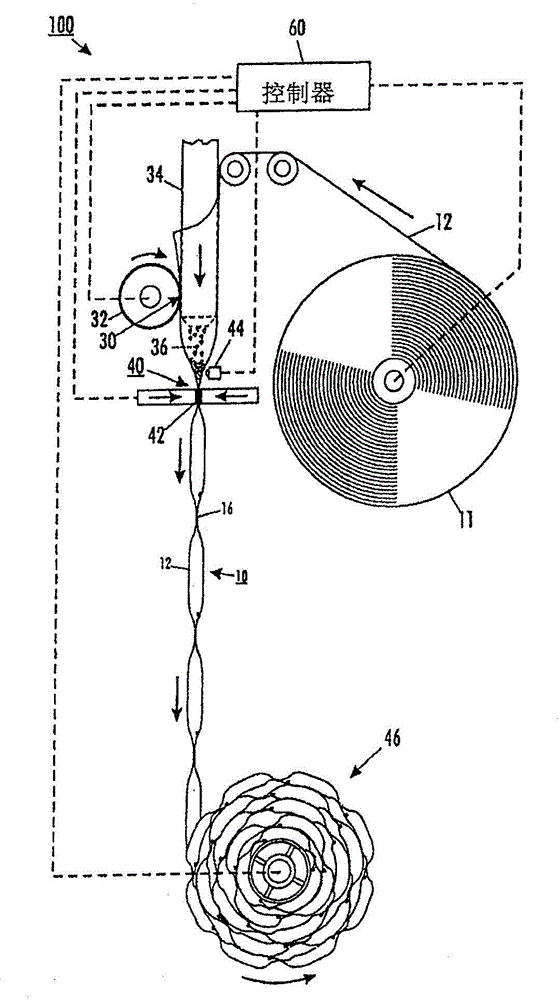

Method used

Image

Examples

Embodiment Construction

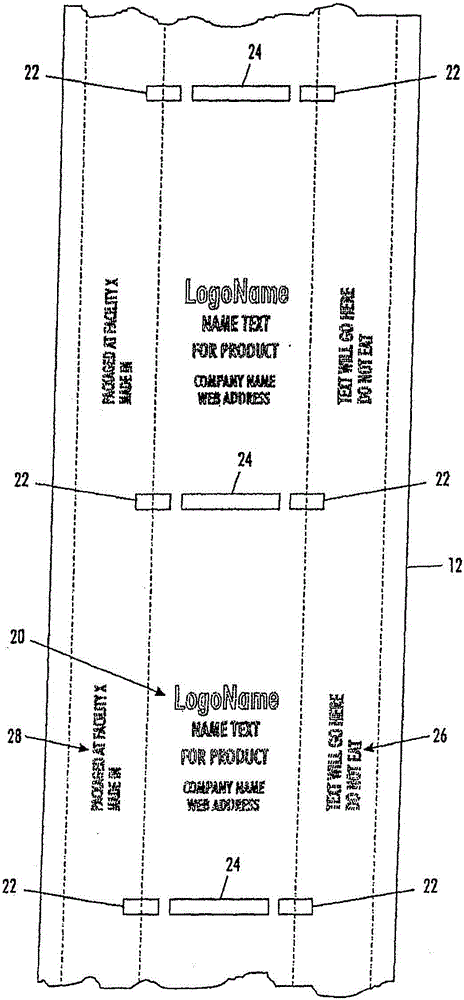

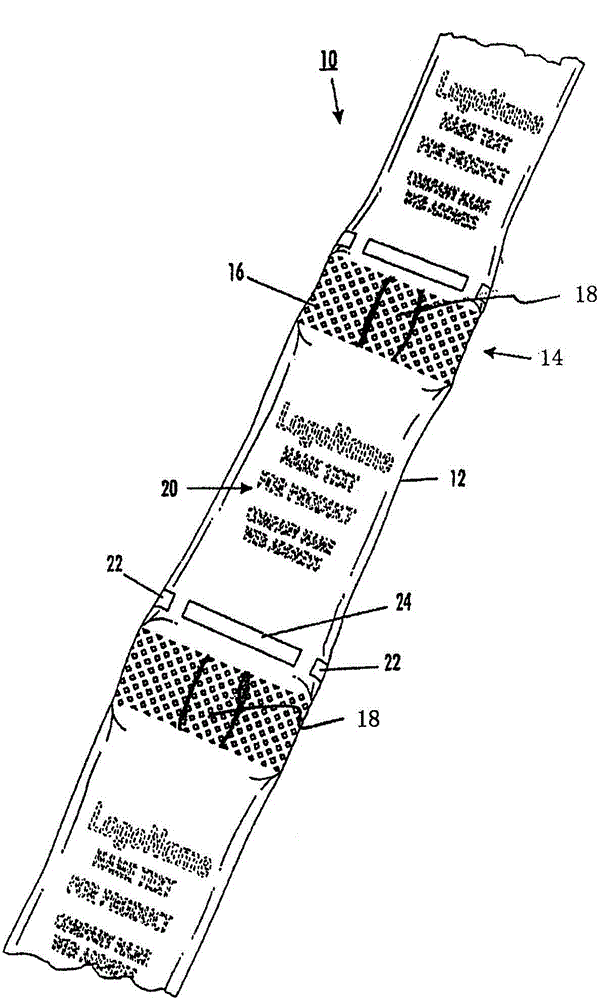

[0024] now refer to figure 1 , shows in diagrammatic form a portion of a strip of sorbent packaging bag according to the present invention. Although these sections of three bags are shown, it is preferred according to the invention to provide a large number of bags in continuous strips, for example 10,000 or 15,000 bags per strip. Once formed, the package is preferably rolled onto a reel and delivered to the consumer in a continuous strip.

[0025] figure 1 The portion of strip 10 shown comprises three packages, all of which are identical. Referring to the bag in the middle, the first end seal 14 is preferably an ultrasonic welded seal in which a plurality of seal points 16 are formed in a hatched arrangement drawn in crossed parallel lines extending over a predetermined length of the bag strip. Preferably, the seal 14 is wide enough, or if considered long enough relative to the longitudinal direction of the strip, to allow the sealed area to be cut in the middle, thereby s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com