A Calculation Method of Critical Air Leakage Amount Caused by Condenser Vacuum Deterioration

A technology of air leakage and vacuum deterioration, applied in the calculation of critical air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0055] A method for calculating the critical leakage air volume that causes the vacuum deterioration of the condenser, comprising the following steps:

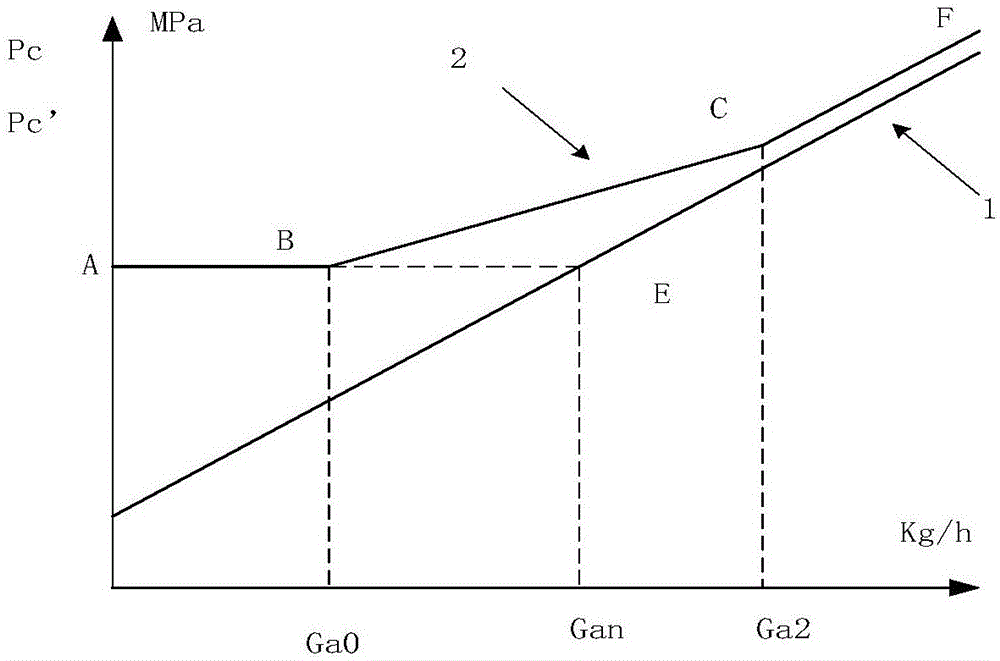

[0056] 1) Cooling water flow D w , cooling water inlet temperature t 1 , air extractor output V H , the steam flow rate G discharged into the condenser s is the measured value, assuming that at any given leakage air volume G a , set the saturated steam temperature t corresponding to the condenser pressure s0 is the initial iteration parameter, and the initial temperature difference of the condenser is obtained by subtracting the cooling water inlet temperature from the steam side temperature.

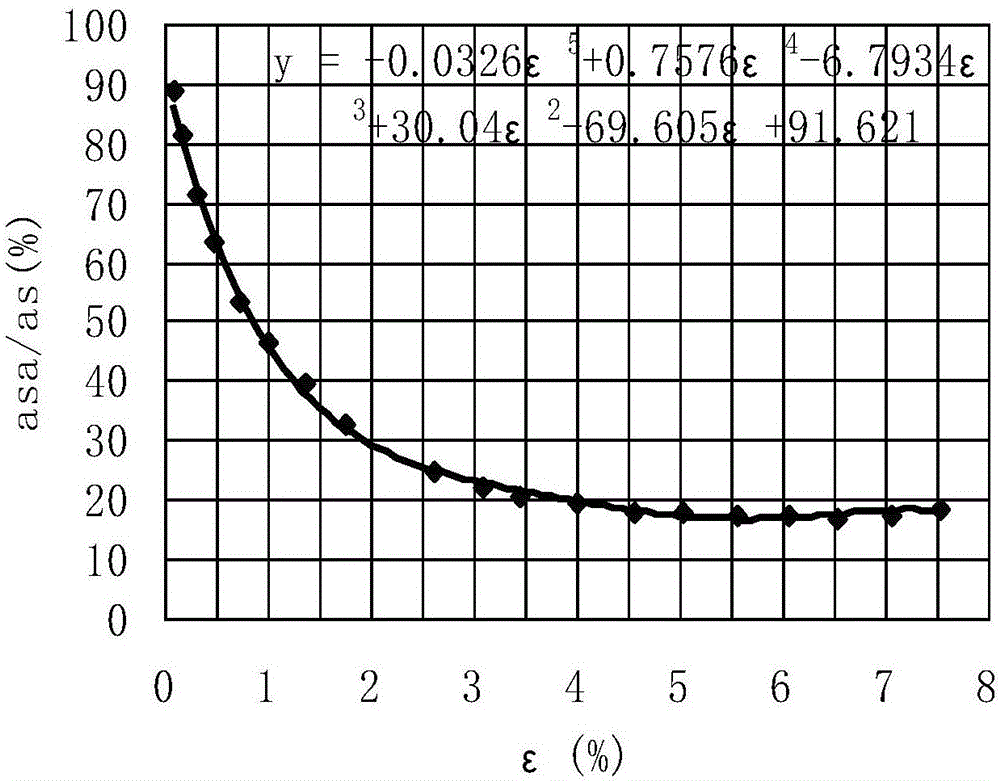

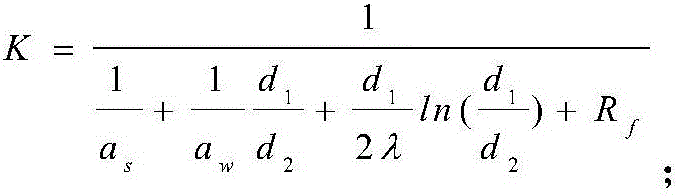

[0057] 2) According to formula (2-21), a s First take the heat release coefficient of pure steam as 17500 to calculate the initial heat transfer coefficient K, and then calculate the cooling water temperature ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com