System and method for testing flow characteristics of gas fuel control valves for gas turbines

A gas turbine and gas fuel technology, which is applied in the field of gas turbine gas fuel control valve flow characteristics test system, can solve the problems of accurate flow adjustment and measurement difficulties, and achieve the effect of solving the precise calibration of flow characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

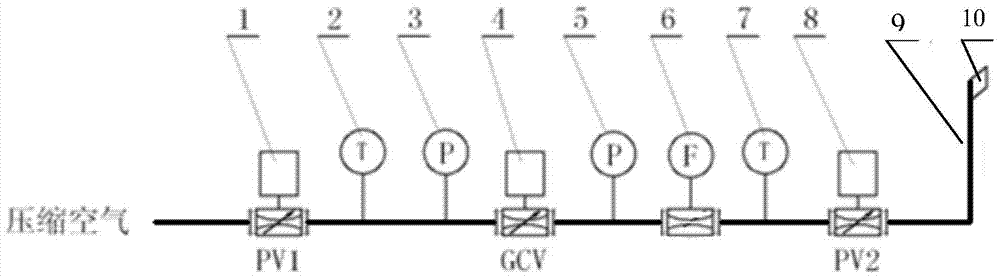

[0019] Embodiment 1: as shown in Figure 1, a kind of gas turbine gas fuel control valve flow characteristic test system of the present invention comprises the intake pipeline and the gas outlet pipeline connected on the control valve 4 to be tested, and the gas supply pipeline is arranged successively on the intake pipeline. Air pressure regulating valve 1, temperature measuring device Ⅰ 2 and pressure measuring device Ⅰ 3, the 1 end of the air supply pressure regulating valve is connected to the compressed air pipeline, the pressure measuring device Ⅰ 3 end is connected to the air inlet port of the tested control valve 4; Set pressure measuring device II5, flow meter 6, temperature measuring device II7 and back pressure regulating valve 8, the end of pressure measuring device II7 is connected to the gas outlet of the control valve 4 under test, and the back pressure regulating valve 8 is close to the exhaust port 10.

[0020] A muffler 9 is also provided at the exhaust port 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com