Tobacco smoke filter

A smoke filter and filter technology, which is applied in tobacco, smoke oil filter elements, and cigar manufacturing, etc., can solve the problems of increasing the complexity and manufacturing cost of carbon groove filters, and unsatisfactory smoke characteristics, etc. Achieve the effect of maintaining smoking experience and maintaining pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

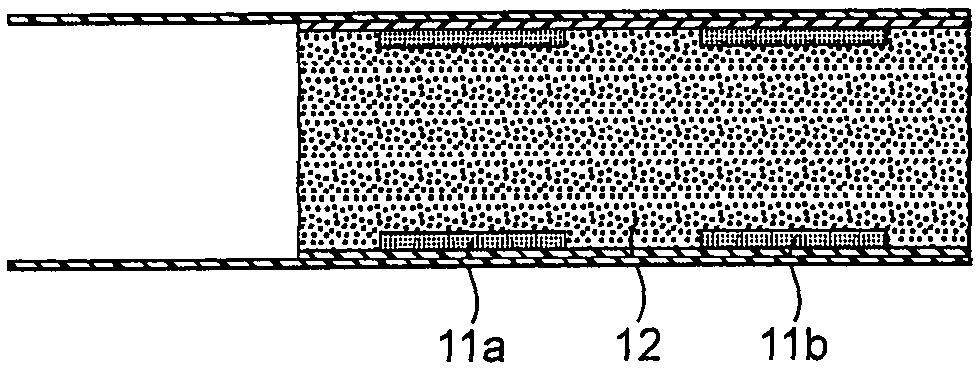

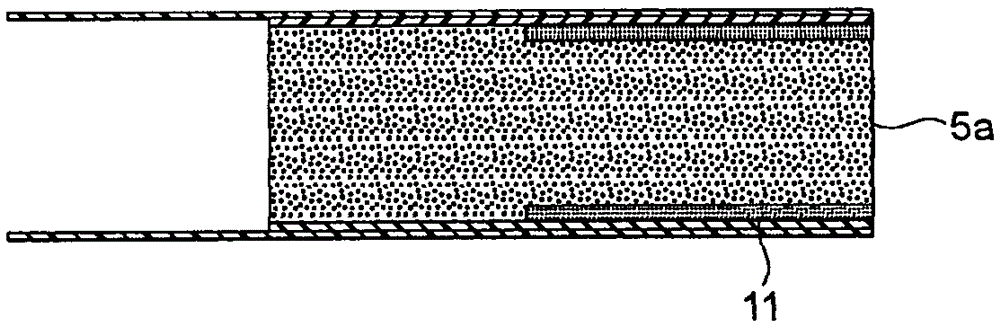

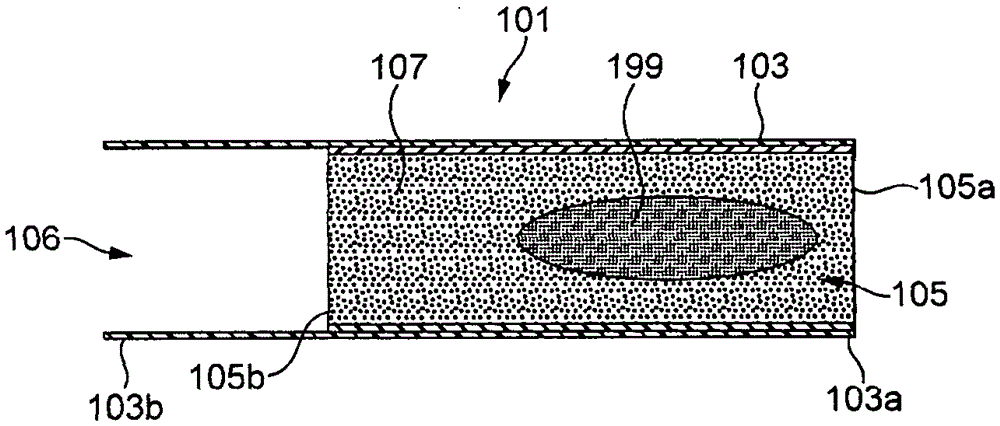

[0025] figure 1 Shown is an 'Active Patch' fluted filter 1 comprising an outer wrapper 3 having a basis weight of 100 g / m 2 The wrapping paper is attached around a single longitudinally extending inner core 5 of tobacco smoke filtering material. The first end 3a of the outer wrapper is substantially flush with the first end 5a of the inner core 5 to which it is attached, and the second end 3b of the outer wrapper extends beyond the second end 5b of the inner core 5 to which it is attached , to define a cavity 6 (groove) at the second (mouth) end of the filter. It will be appreciated that it is the radially inner surface of the outer wrapper 3 that extends beyond the second end 5b of the inner core at which the filter second end, together with the second end 5b of the longitudinally extending inner core, delimits a tubular cavity (recessed slot) 6. The single longitudinally extending core 5 of tobacco smoke filtering material is an "active patch" filter element, as is well k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com