An antibacterial air filter membrane based on polyacrylonitrile/graphene oxide/tea polyphenol composite and its preparation method

A technology of polyacrylonitrile and air filter membrane, which is applied in the direction of chemical instruments and methods, separation methods, membranes, etc., can solve the problem of large gaps and cannot effectively filter small air particles, and achieve excellent permeability, increase filtration effect, Good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

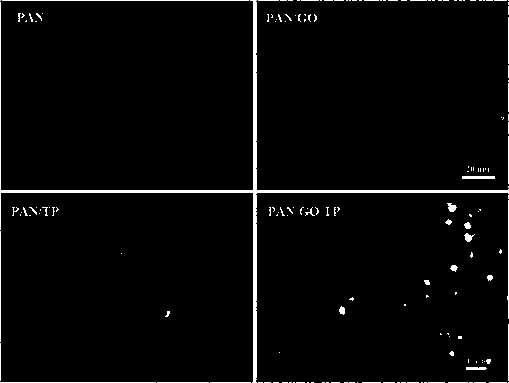

Image

Examples

Embodiment 1

[0024] An antibacterial air filter membrane based on polyacrylonitrile / graphene oxide / tea polyphenol composite, with non-woven fabric as the substrate, and the surface of the substrate is deposited with polyacrylonitrile / graphene oxide / tea polyphenol composite The composite film, the mass ratio of polyacrylonitrile, graphene oxide, and tea polyphenols is 16:4:8, the thickness of the substrate is 0.07mm, and the thickness of the composite film is 0.03mm.

[0025] The method for preparing the antibacterial air filter membrane based on polyacrylonitrile / graphene oxide / tea polyphenol composite comprises the following steps:

[0026] 1) Preparation of graphene oxide DMF dispersion: Add 50 g of DMF solution to 50 g of graphene oxide aqueous dispersion with a concentration of 2 mg / ml to obtain a mixed dispersion, and place the mixed solution in a rotary evaporator to rotate to its peak value. The quality does not change significantly (the quality difference of the last two rotary-eva...

Embodiment 2

[0032] An antibacterial air filter membrane based on polyacrylonitrile / graphene oxide / tea polyphenol composite, with non-woven fabric as the substrate, and the surface of the substrate is deposited with polyacrylonitrile / graphene oxide / tea polyphenol composite composite film, the mass ratio of polyacrylonitrile, graphene oxide and tea polyphenol is 30:10:16. The thickness of the base material is 0.07mm, and the thickness of the composite film is 0.03mm.

[0033] The method for preparing the antibacterial air filter membrane based on polyacrylonitrile / graphene oxide / tea polyphenol composite comprises the following steps:

[0034] 1) Preparation of graphene oxide DMF dispersion: Add 50 g of DMF solution to 50 g of graphene oxide aqueous dispersion with a concentration of 2 mg / ml to obtain a mixed dispersion, and place the mixed solution in a rotary evaporator to rotate to its peak value. The quality does not change significantly (the quality difference of the last two rotary-evap...

Embodiment 3

[0039] An antibacterial air filter membrane based on polyacrylonitrile / graphene oxide / tea polyphenol composite, with non-woven fabric as the substrate, and the surface of the substrate is deposited with polyacrylonitrile / graphene oxide / tea polyphenol composite The composite film, the mass ratio of polyacrylonitrile, graphene oxide, and tea polyphenols is 16:4:4, the thickness of the substrate is 0.07mm, and the thickness of the composite film is 0.03mm.

[0040] The method for preparing the antibacterial air filter membrane based on polyacrylonitrile / graphene oxide / tea polyphenol composite comprises the following steps:

[0041] 1) Preparation of graphene oxide DMF dispersion: Add 50 g of DMF solution to 50 g of graphene oxide aqueous dispersion with a concentration of 2 mg / ml to obtain a mixed dispersion, and place the mixed dispersion in a rotary evaporator to rotate to its mass No change (take the quality difference of the last two rotary steamed mixtures in the sampling in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com