Printed circuit board

A technology of printed circuit boards and conductive layers, applied in the direction of printed circuit components, etc., can solve the problems of small trace width and increase PCB manufacturing cost, and achieve the effect of improving power supply and return flow capacity, enhancing stability, and facilitating heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] According to the resistance formula: R = ρ l A

[0017] Among them, ρ is the resistivity, l is the length of the wire, A is the cross-sectional area,

[0018] In the case of constant resistivity and thickness, the trace area should be increased as much as possible.

[0019] In addition, according to the ideal return path ground bounce voltage drop formula:

[0020] Among them, V gb is the ground bounce voltage, L total is the total return path inductance, L b is the local self-inductance, L ab is the local mutual inductance,

[0021] It can be deduced that when the signal edge change rate cannot be reduced and the number of layers of the PCB return path cannot be reduced, the trace width should be increased as much as possible.

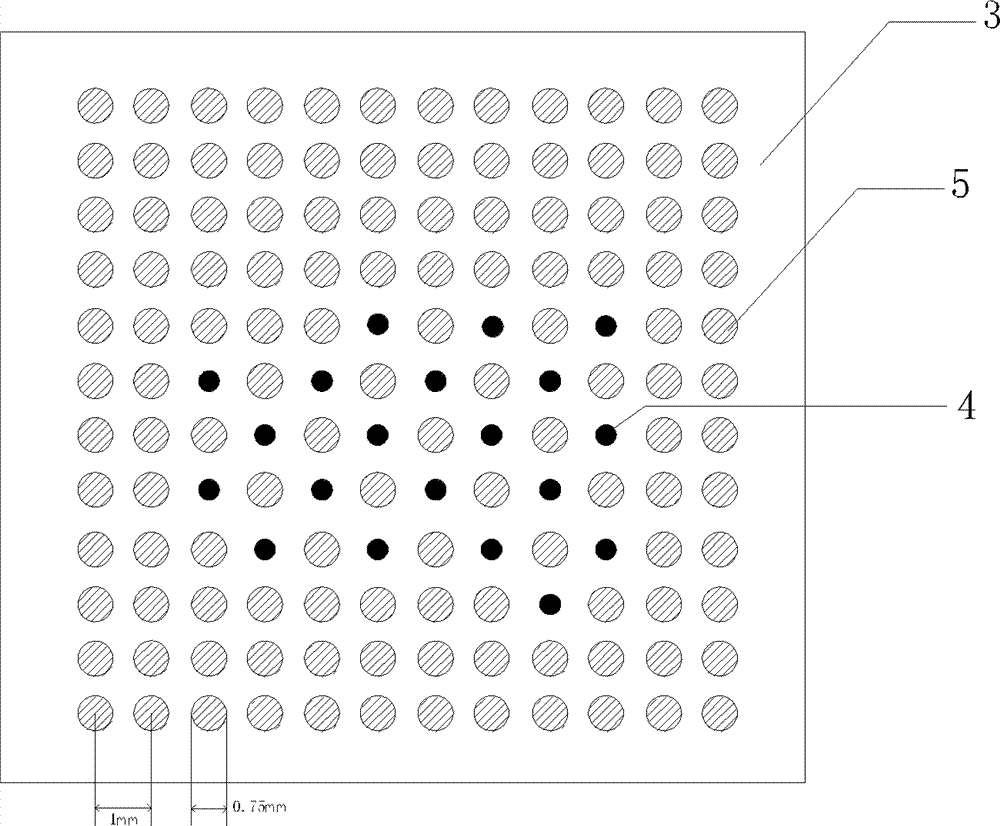

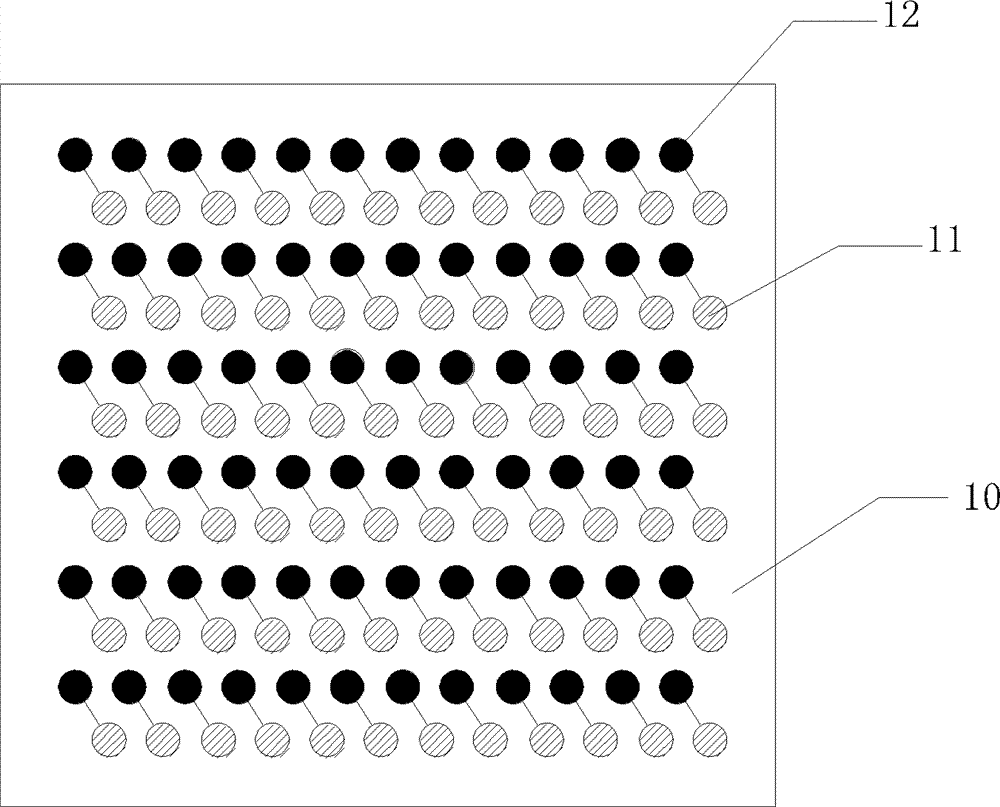

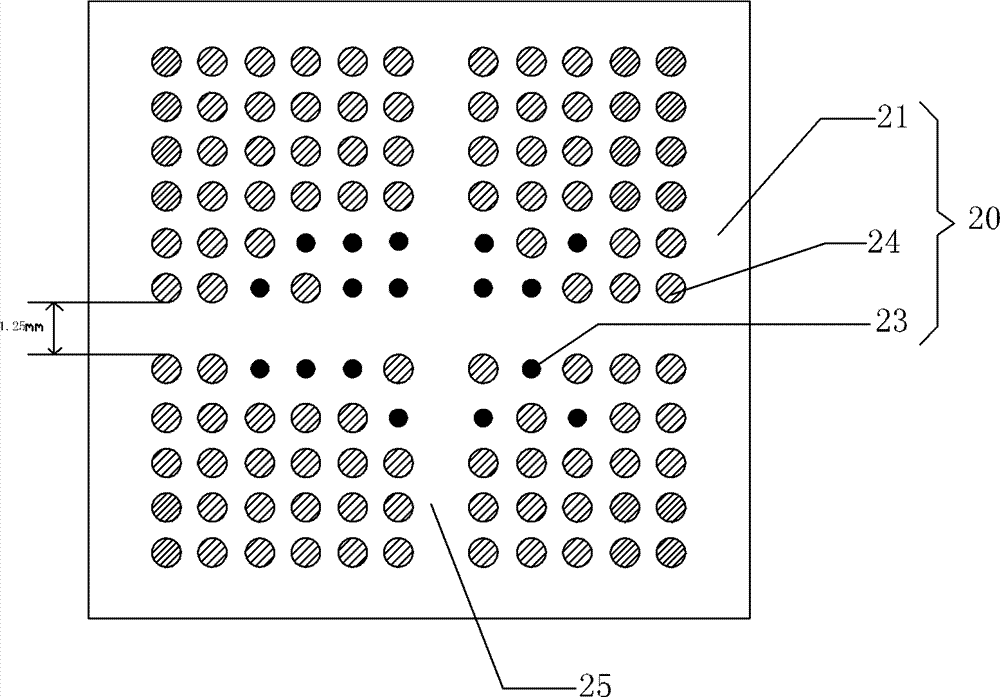

[0022] The PCB board of the present invention includes a surface layer board 10 , a power plane layer board 20 , a ground layer board 30 and a bottom layer boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com