Spring connection element

A technology of spring connection and components, which is applied in the direction of connecting components, threaded fasteners, friction clamping detachable fasteners, etc., and can solve the problem of not being able to prevent radial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

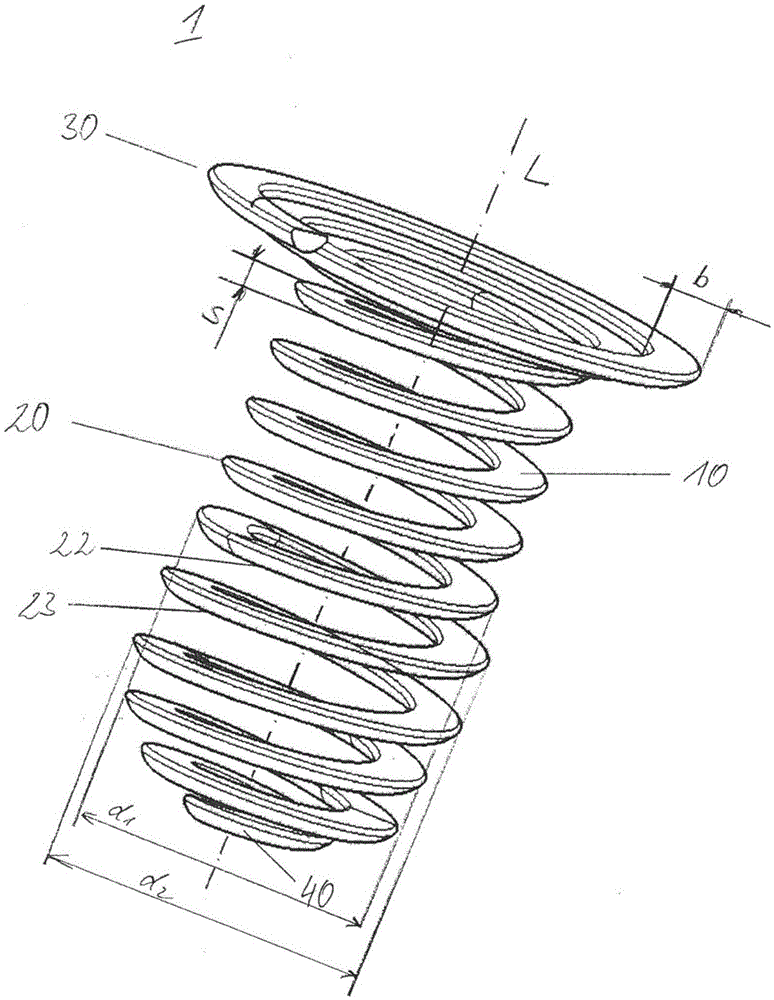

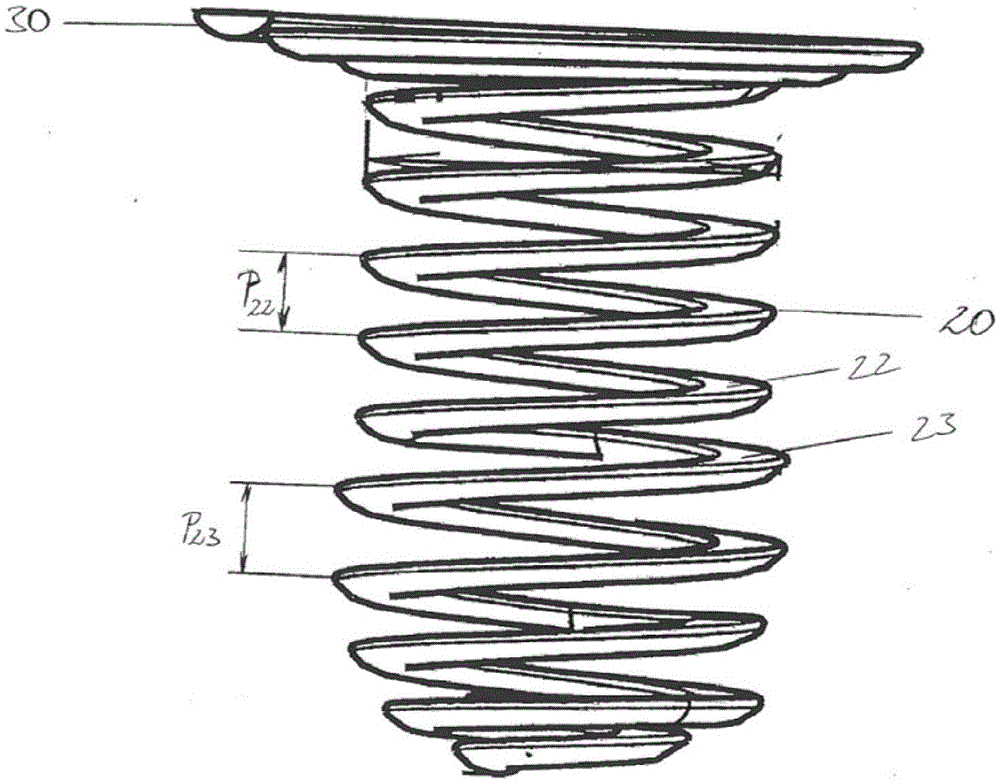

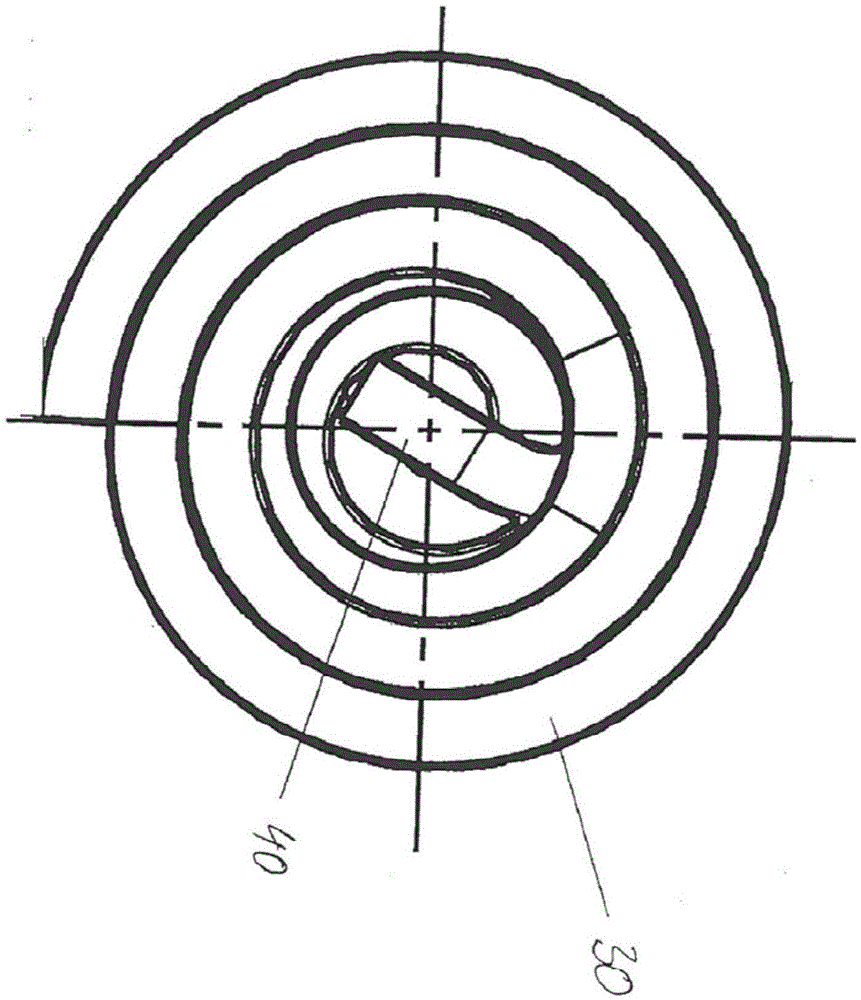

[0045] The spring connection element 1 is wound by a wire 10 with a given cross-sectional profile. The spring connection element 1 comprises a helical spring-like wire coil 20 with a helical journal 30 at a first end and a central pulling element 40 at a second end. The wire coil 20 includes a plurality of meanders 22 spaced apart from each other in the axial direction and irregularly shaped. According to the invention, the wire coil 20 preferably has a certain outer diameter d 1 . The fact that the meanders 22 are regularly or irregularly shaped leads to the fact that the different meanders 22, 23 have different outer diameters d in the preferred embodiment 1 and d 2 (See figure 1 ).

[0046] The preferred spiral pin 30 is formed from the same wire 10 as the rest of the spring connection element 1 . The spiral journal 30 is wound helically in a radial plane. Thus, the helical collar 30 has a larger outer diameter than the wire coil 20 . Furthermore, the helical collar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com