New self-weight keyboard typing module

A keyboard, a new type of technology, applied in the field of new self-weight keyboard percussion modules, can solve the problems of inconvenient maintenance, difficult connection, narrow operation and assembly space, etc., to achieve convenient assembly, maintenance and operation, stable percussion force output, The effect of high test pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

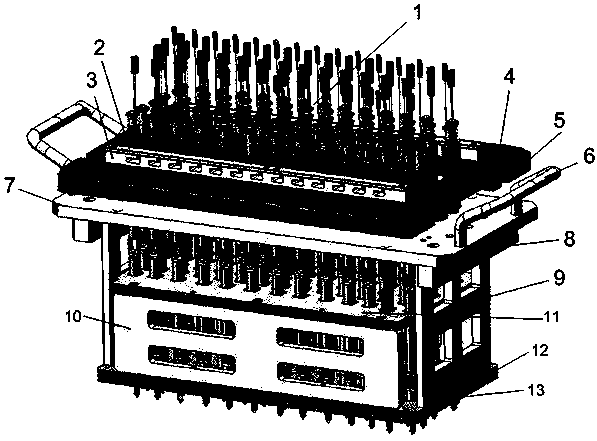

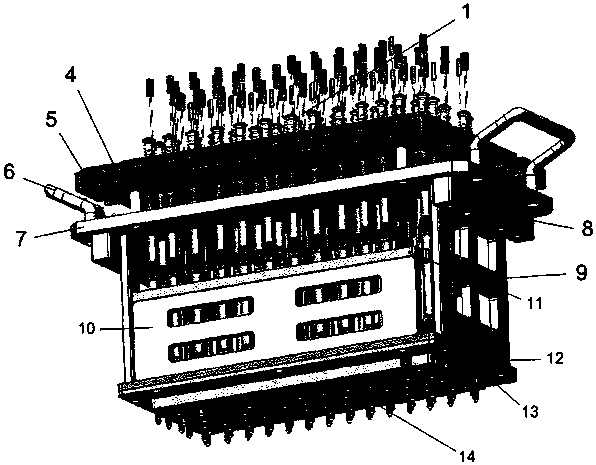

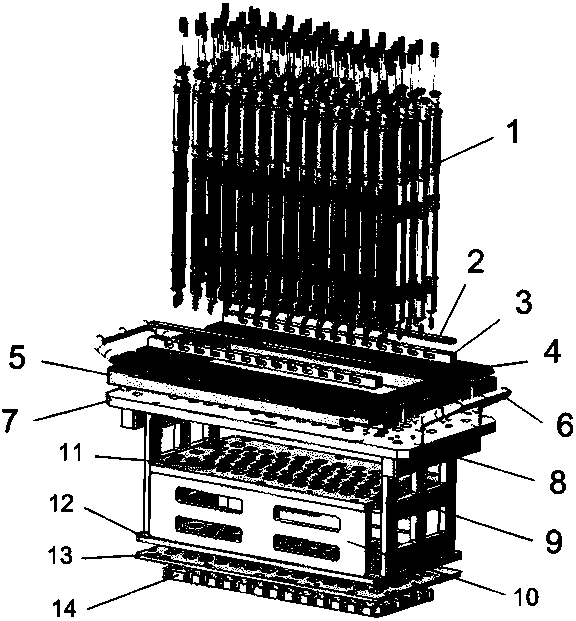

[0022] like Figure 1 to Figure 3 As shown, in the present embodiment, the present invention includes several knocking rods 1, PCB board 4, PCB board fixing frame 5 and electromagnet fixing plate 7, and several described knocking rods 1 are arranged on the fixed position of the electromagnet. On the plate 7, below the electromagnet fixing plate 7, there are guide plates 11 that are compatible with several knocking rods 1, and the PCB board fixing frame 5 is located above the electromagnet fixing plate 7, so that The PCB board fixing frame 5 is provided with placement holes, and the tops of several knock bars 1 pass through the placement holes, and the PCB board 4 is fixedly arranged on the PCB board fixing frame 5, and the PCB The plate 4 is provided with a through hole adapted to the placement hole.

[0023] In this embodiment, handles 6 are provided on both sides of the electromagnet fixing plate 7, and the handles 6 are angled handles.

[0024] In this embodiment, the PCB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com