A Design Structure of the Breakthrough Hole for a Chip Resistor in a Power Divider with Wires

A technology of designing structure and giving way holes, applied in circuits, electrical components, waveguide-type devices, etc., can solve the problems of circuit performance degradation, deterioration, discontinuity, etc., to improve the processing yield, reduce deformation problems, and improve processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

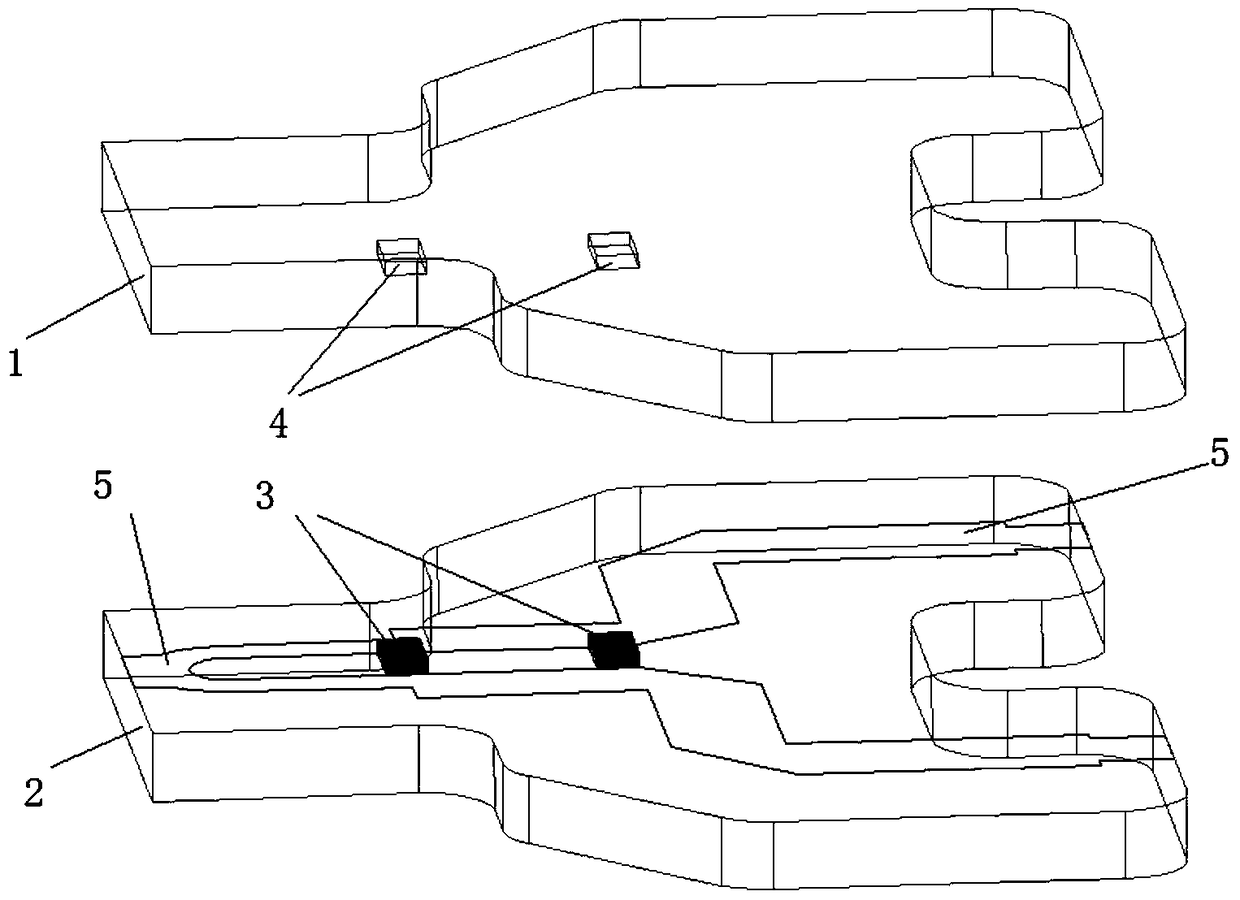

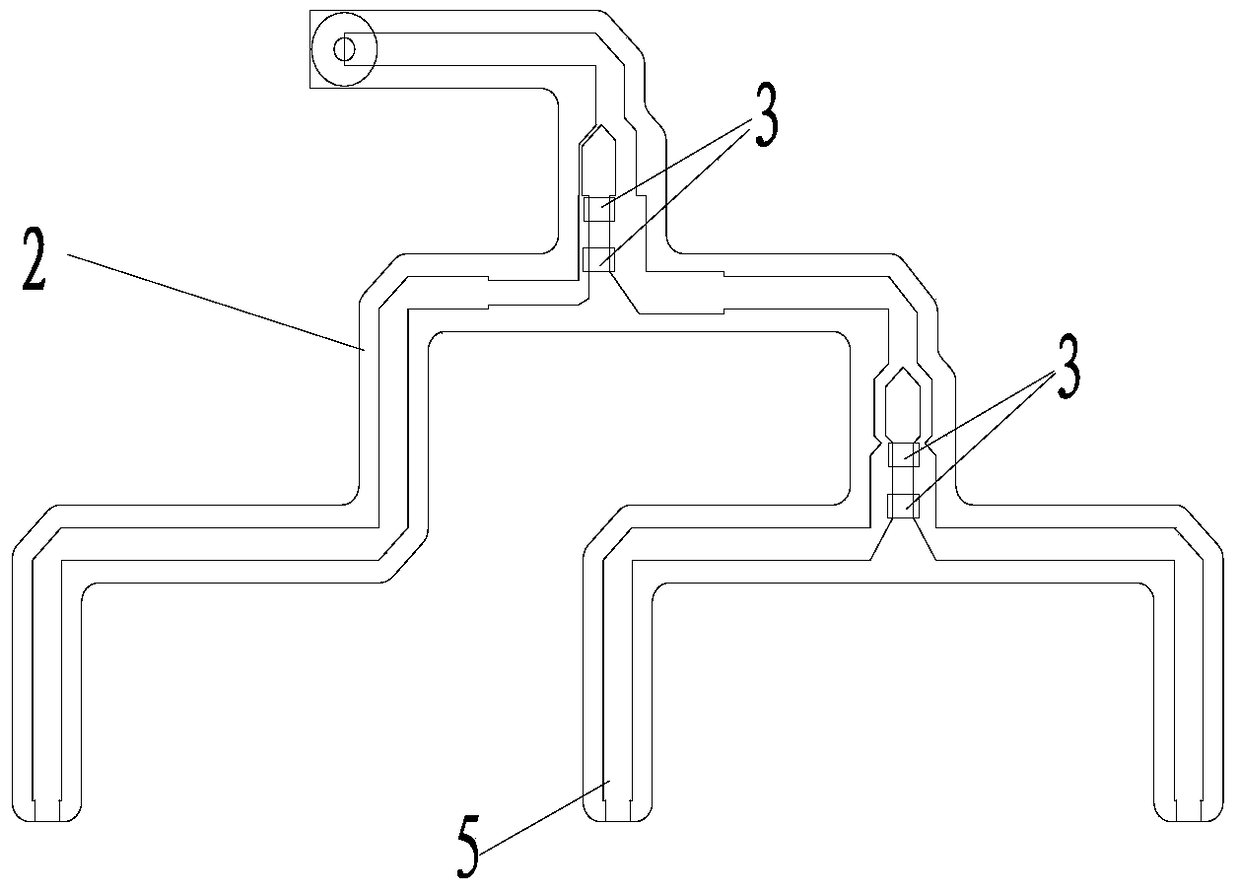

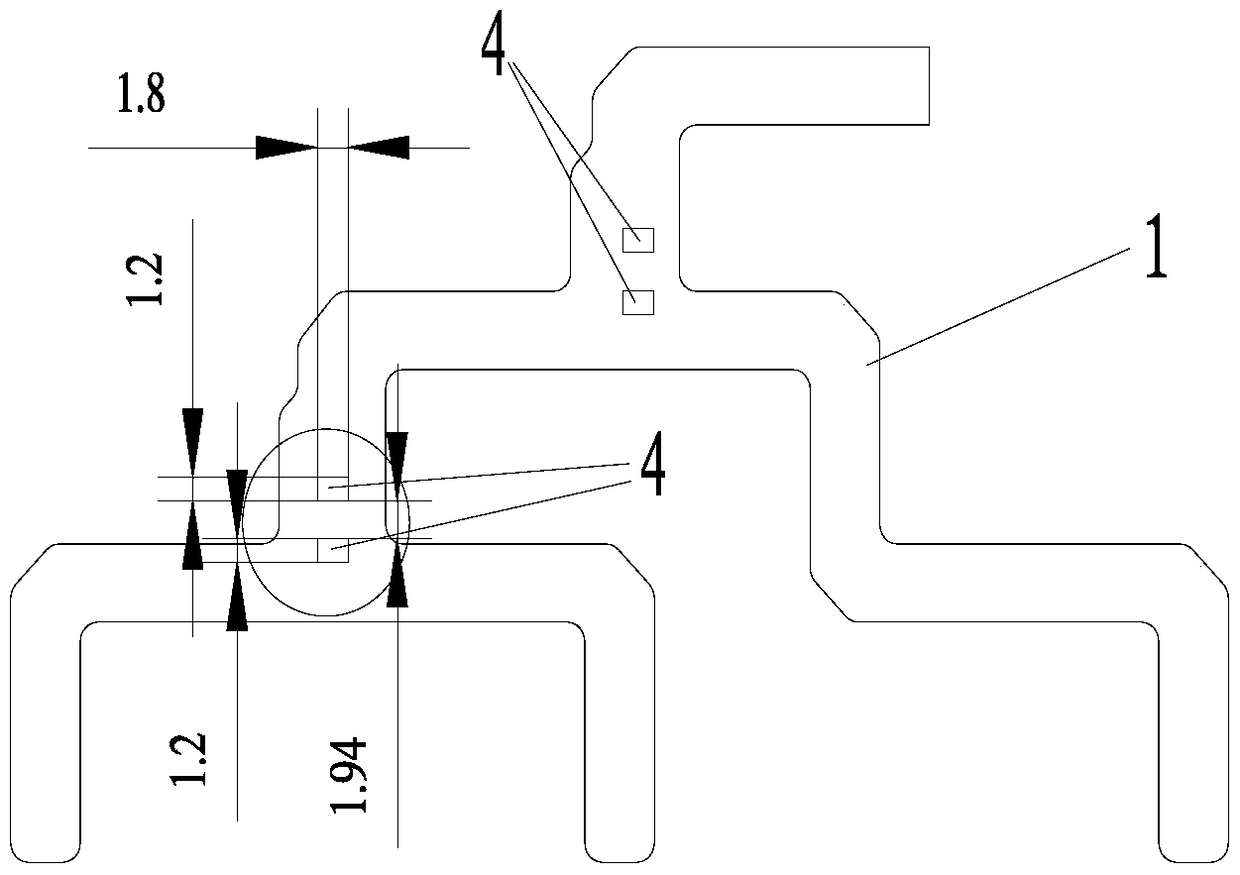

[0044] figure 2 , Figure 4 As an example of the method of the present invention, a single 8mm by 3mm resistor make way hole replaces the original image 3 2 1.8mm by 1.2mm resistors from the old method give way to holes and machined stepped resistor covers in the same area ( Figure 5 , Image 6 ) to match it.

example 2

[0046] Figure 7 , Figure 9 As an example of the method of the present invention, a single 14mm by 3mm resistor make way hole replaces the original Figure 8 4 well-spaced 1.8mm by 1.2mm resistors give way to holes in the old method and machined stepped resistor covers in the same area ( Figure 10 , Figure 11 ) to match it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com