Novel workpiece mounting and positioning device

A technology for installing positioning and clamping devices, which is applied in the field of workpiece clamping and can solve problems such as workpiece damage, rising operating costs, and waste of work and operating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

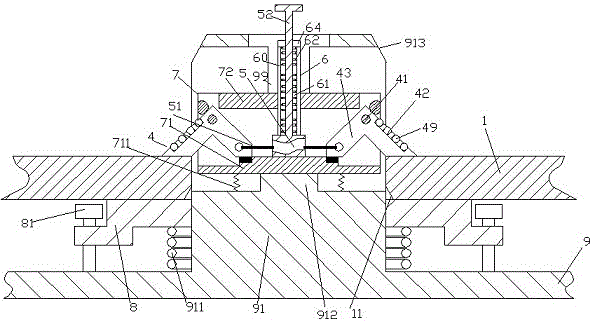

[0007] Combine below figure 1 The present invention will be described in detail.

[0008] A novel workpiece installation and positioning device according to an embodiment of the present invention is used for installing and positioning the workpiece 1, comprising a fixed frame 9, which is installed in the inner cavity of the fixed column 91 of the fixed frame 9 and can be positioned along the The guide rail 99 fixed in the internal cavity slides up and down the movable locking device 7, and the telescopic return spring 711 interposed between the fixed upright 91 and the bottom wall 71 of the movable locking device 7, Wherein, the fixed column 91 is covered with a pressure plate 8 pressed by the pressure positioning spring 911 and guided and limited by the limit column 81, and the movable locking device 7 includes two symmetrically arranged pivots. Each pivot arm 4 is pivotally connected to a respective pivot pin 41 fixed on the shell wall of the movable locking device 7 and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com