A shell riveting device

A casing and riveting technology, which is applied in metal processing equipment, feeding devices, positioning devices, etc., can solve problems such as inability to align riveting processing, full refrigerator casings, and excessive volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

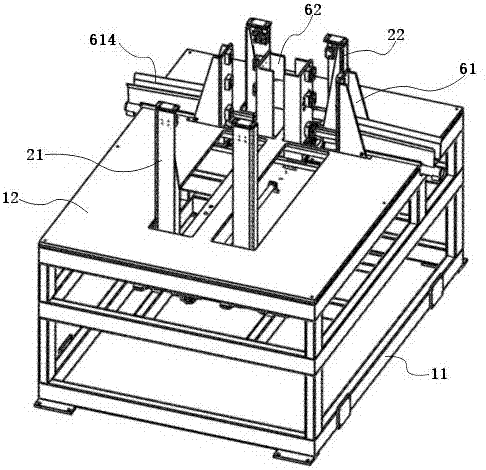

[0030] Image 6 It is a schematic diagram of the shell structure processed in this embodiment. The housing consists of two parts, a large part 91 and a small part 92 . The large part 91 and the small part 92 of the shell are processed independently and spliced to form an integral stepped shell. The joint part 93 between the large part 91 and the small part 92 of the shell needs to be reinforced by riveting the shell. The shell riveting equipment of this embodiment is used for the shell riveting reinforcement of the splicing part, such as figure 1 As shown, it includes a frame 11, a support mechanism at the four corners of the housing and a riveting mechanism for the housing. The frame 11 is a square frame structure, and the top is a work platform 12 .

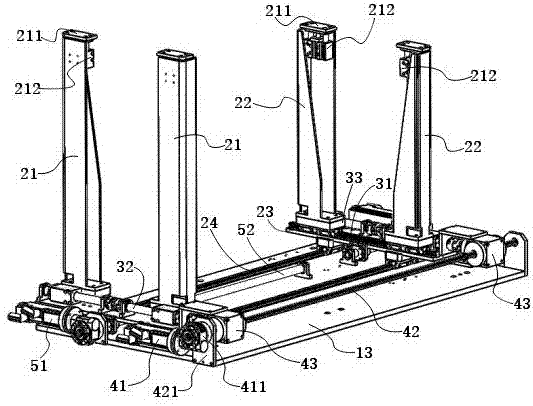

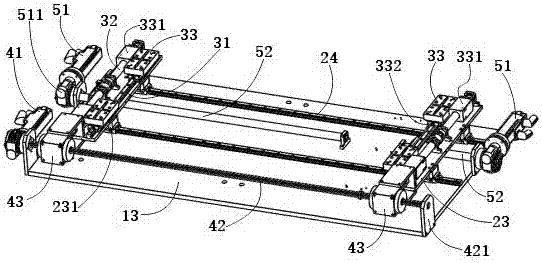

[0031] The supporting mechanism in the four corners of the shell, such as figure 1 , figure 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com