A water-stopping structure with grooves at the top of an anti-seepage wall

A technology for anti-seepage walls and waterstops, which is applied in water conservancy projects, sea area projects, buildings, etc. It can solve problems such as no space for asphalt compression, unknown structural damage, and failure of asphalt waterstops, so as to avoid the risk of waterstop failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

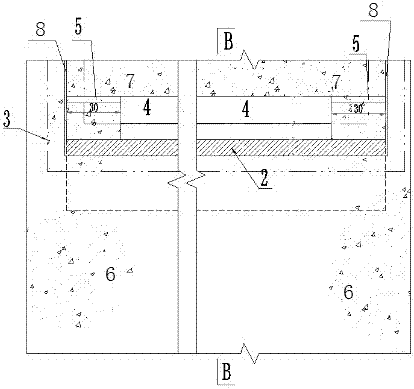

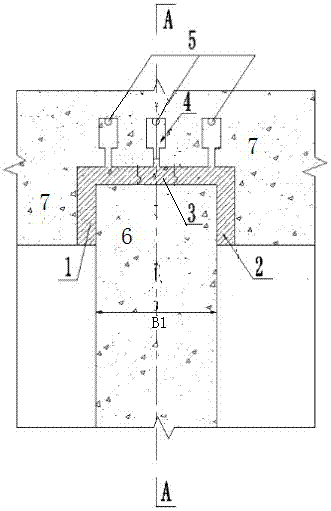

[0023] like figure 1 , figure 2 As shown, the present invention provides a water-stopping structure with grooves at the top of the cutoff wall, which is suitable for the situation where the cutoff wall is arranged at the bottom of buildings such as lock chambers or retaining walls. The present invention comprises the groove 1 that is located at the bottom surface 7 of the building at the top of the anti-seepage wall 6, that is, the bottom surface of the building at the top of the anti-seepage wall 6 is arranged according to the design requirements such as figure 2 The groove 1 in the groove 1 is located between the top of the anti-seepage wall 6 and the bottom surface 7 of the building, and the plastic impermeable material 3 is embedded, and the vertical width of the groove 1 is adapted to the distance between the building and the anti-seepage wall 6. The settlement is poor, and the width of both sides of the groove 1 is adapted to the horizontal displacement between the b...

Embodiment 2

[0025] On the basis of Example 1, the impermeable material 3 is an SR plastic water-stop material, and its indicators meet the design requirements for anti-seepage and various physical property indicators; the several outflow boxes 4 are divided into multiple groups, A group of outflow boxes 4 is arranged between every two adjacent expansion joints 8 on the bottom surface of the building 7, and each group of outflow boxes 4 includes a plurality of outflow boxes 4, and the plurality of outflow boxes 4 are arranged in a row, and the arrangement direction The width direction of the expansion joint 8 and the anti-seepage wall 6 is consistent, the distance between two adjacent outflow boxes 4 in each group of outflow boxes 4 is 0.3 meters, and the number of outflow boxes in each group is determined according to the width B1 of the anti-seepage wall n (n is an integer value of B1 / 0.3m), the outflow box 4 is made of galvanized tinplate. Its main body cavity of described outflow box 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com