Dual-step double-precision electronic weighing scale having adjusting mechanism

An adjustment mechanism and double-precision technology, applied to the detailed information of weighing equipment, weighing, special scales, etc., can solve the problems of large errors, use, and inability to be used as a weight scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

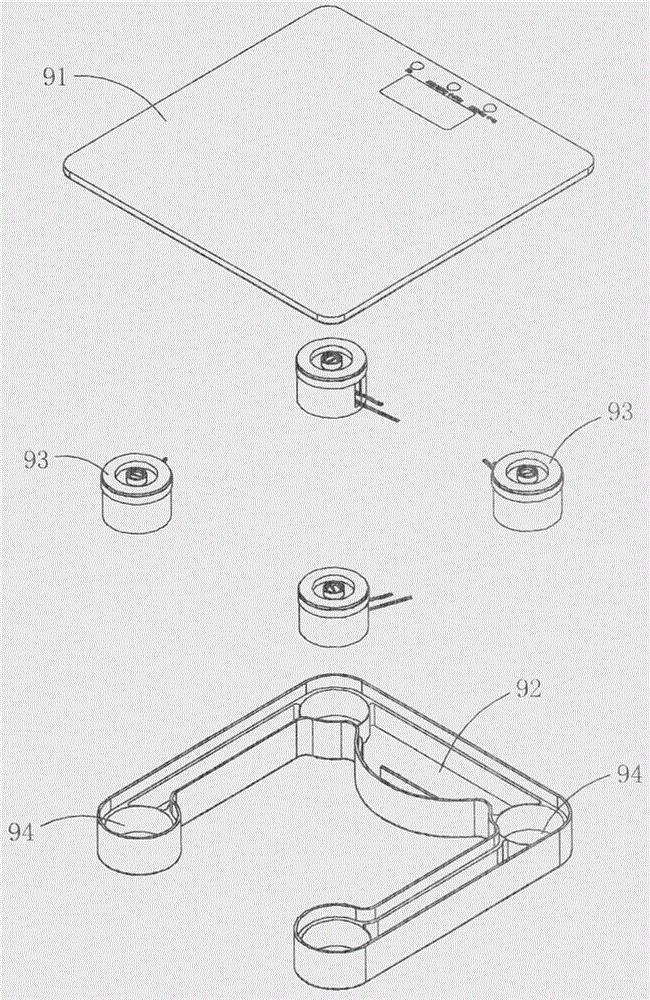

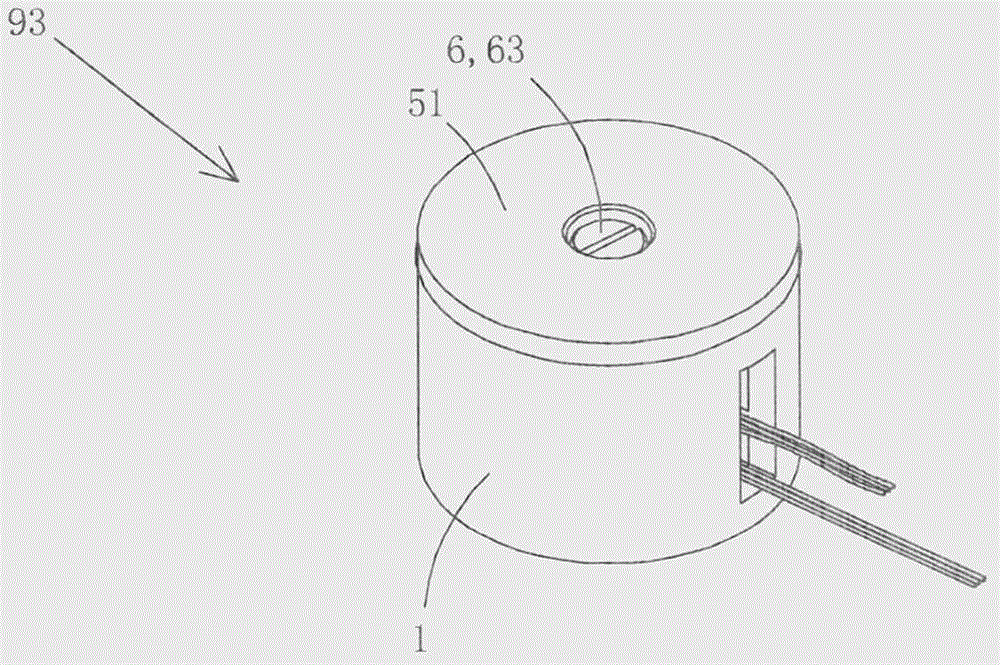

[0017] This embodiment is a double-stage double-precision weighing electronic scale with an adjustment mechanism, see Figure 1 to Figure 7 As shown, it includes a loading plate 91 for placing objects to be weighed, a base 92 arranged below the loading plate and four double-stage double-precision load cells 93 for supporting the loading plate arranged in the base; There are four through holes 94 in the base, and each double-stage double-precision weighing sensor is fixed in a corresponding through hole by bonding.

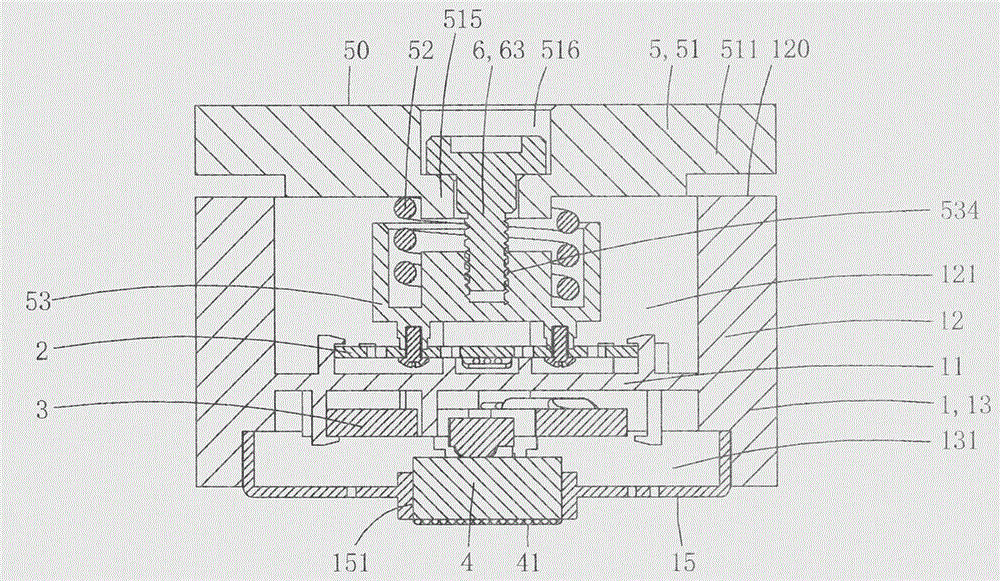

[0018] Each double-stage double-precision load cell includes a mount 1, a first-precision load cell 2, a second-precision load cell 3, a supporting foot 4, an elastic support 5 and an adjustment mechanism 6 for adjusting the height of the elastic support.

[0019] The mounting seat is provided with a mounting plate portion 11 and a force guiding support portion 12 for transmitting the pressure received by itself to the mounting plate portion; an elastic support mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com