A kind of auxiliary turning method and auxiliary turning mechanism

A technology of a jacking mechanism and a driving mechanism, which is used in medical science, hospital beds, hospital equipment, etc., can solve the problems of easy loosening and sliding of mattresses, uncomfortable reclining people, and uneven force on the back of the body. Inconvenient to turn over, good effect of turning over

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

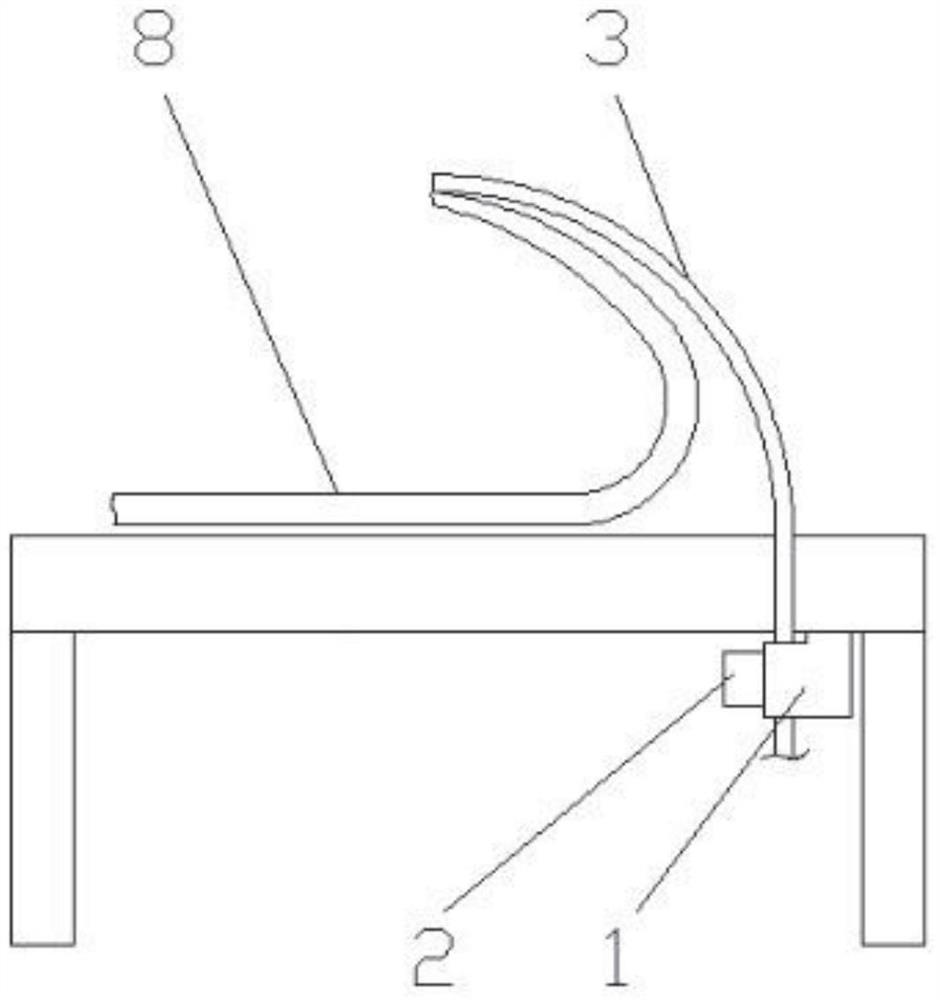

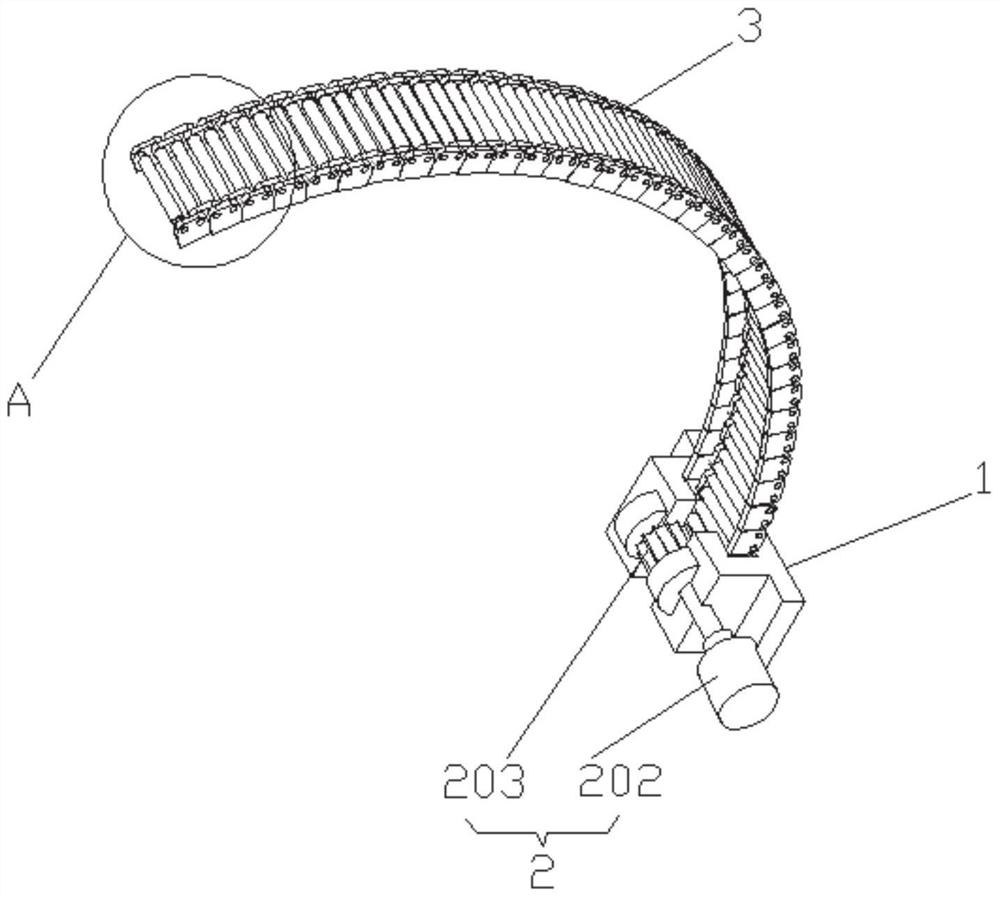

[0039] Such as figure 2 , 3 , 4, in this embodiment, the structure of the auxiliary turning mechanism includes a jacking mechanism 3 that is arranged on the side of the bed and can move up and down. During the movement, it can be bent into a strip-shaped rigid arc structure, and the upper end of the jacking mechanism 3 is fixedly connected with the side edge of the mattress mattress 8 . The jacking mechanism 3 is bent towards the opposite side of the bed body.

[0040] The auxiliary turning mechanism also includes a guiding mechanism 1 and a driving mechanism 2, the jacking mechanism 3 is arranged in the guiding mechanism 1, the lower end passes through the guiding mechanism 1, and is connected with the lower driving mechanism 2, and the driving mechanism 2 drives the jacking mechanism 3 Move up and down in the guide mechanism 1 to drive the mattress 8 to turn over. The jacking mechanism 3 is a rigid arc structure or can be bent into an arc structure during the upward jacki...

Embodiment 2

[0048] Embodiment 2 is another improvement to the jacking mechanism 3 in the above embodiment 1, and its specific structure is:

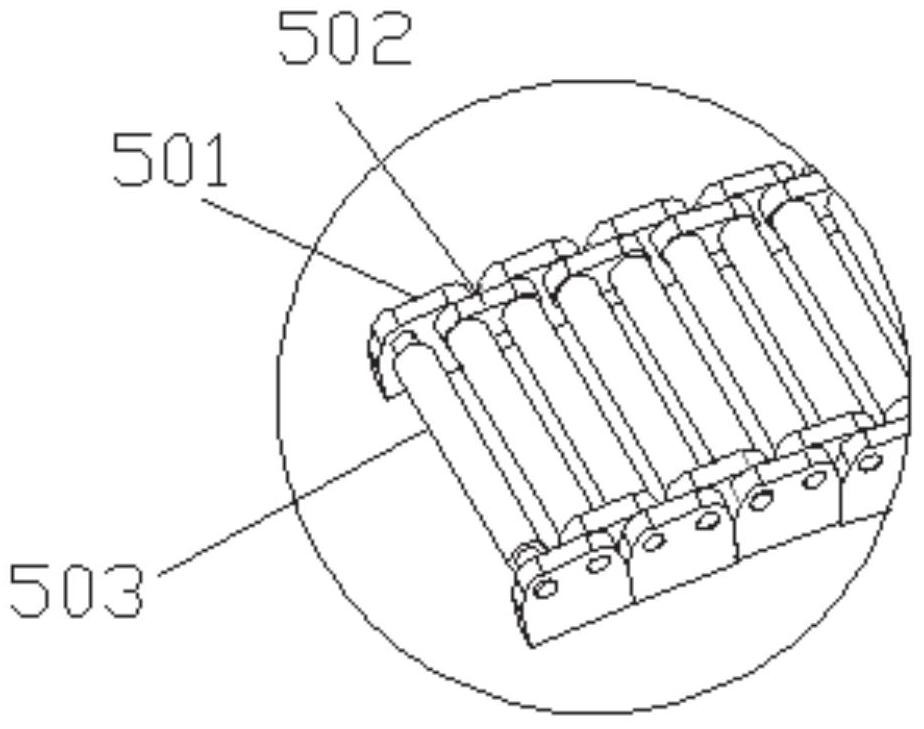

[0049] Such as Figure 5 , 6 , 7, the jacking unit includes a square base plate 401, a group of opposite sides of the square base plate 401 are respectively provided with a side plate 402 perpendicular to the base plate 401, and the other set of opposite sides are respectively connected to the corresponding The base plate 401 adjacent to the jacking unit is hinged, and the two side plates on the same side of the adjacent jacking unit have side surfaces 404 that can be attached to each other, and the two sides are inclined surfaces in opposite directions, so that the jacking mechanism 3 After being jacked up by the driving mechanism 2, an arc-shaped elongated structure with rigidity is formed.

[0050] A straight tooth 403 vertical to the side between the two side plates 402 is arranged on the base plate 401, and the driving mechanism 2 includes a ...

Embodiment 3

[0053] In this embodiment, on the basis of the second embodiment, the transmission mode of the jacking mechanism 3 and the driving mechanism 2 is improved to a screw thread meshing transmission. The working principle is the same as that of the second embodiment, and the relevant specific structures are as follows:

[0054] Such as Figure 8 , 9 , 10, in this embodiment, one side of the base plate 601 located between two side plates 602 is provided with a threaded groove 603 axially along the length direction of the jacking mechanism 3, similarly, adjacent jacking units The two side plates positioned on the same side have side surfaces 604 that can be attached to each other, and the two side surfaces are inclined surfaces in opposite directions. The driving mechanism 2 includes a driving motor and is connected with the output shaft of the driving motor and can be connected with the jacking unit. The threaded rod 204 engages the threaded groove of the body.

[0055] Like the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com