A method for chewing mechanical teeth and simulating chewing

A technology of mechanical teeth and chewing teeth, which is applied in the field of bionic machinery and can solve problems such as the inability to imitate the dynamic update process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

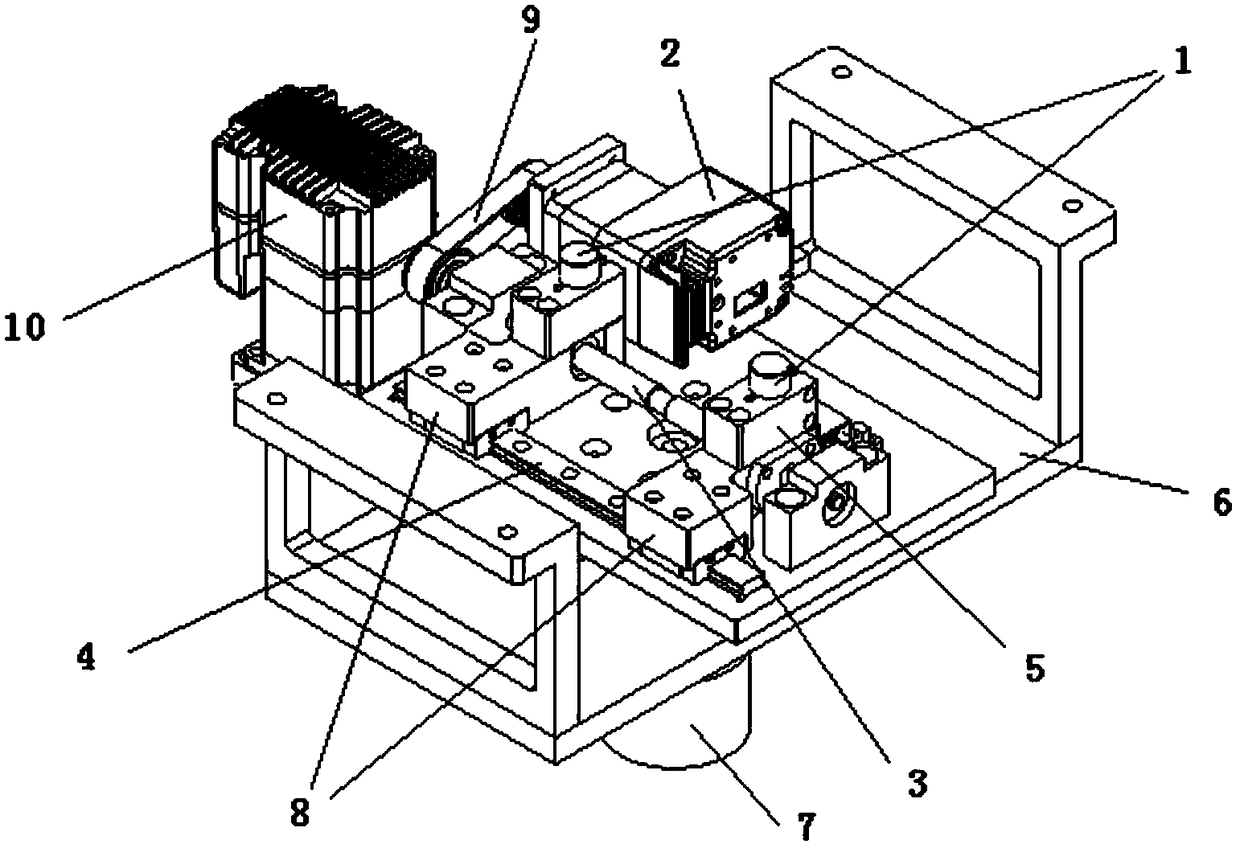

[0051] Use as attached Figure 6 The chewing machine teeth shown chew gum-based chewing tobacco.

[0052] Put one piece of gum-based chewing tobacco into the solution dish, add 10mL of artificial saliva, and set the chewing mechanical teeth. The working process is as follows: select 5Kg weight assembly 4 and install it on the upper chewing lifting shaft 6, and set it to bite up and down at a frequency of 5 seconds. 20 times, set each chewing action to rotate 180° when the upper chewing lifting shaft drops 20mm to achieve left and right grinding. After biting up and down and rubbing right and left 20 times in this way, the gum-based chewing tobacco was completely broken with the cooperation of another artificial tongue. The solution in the solution dish was drained for main component analysis, and the remaining gum-based chewing tobacco samples were taken out for further analysis and testing.

Embodiment 2

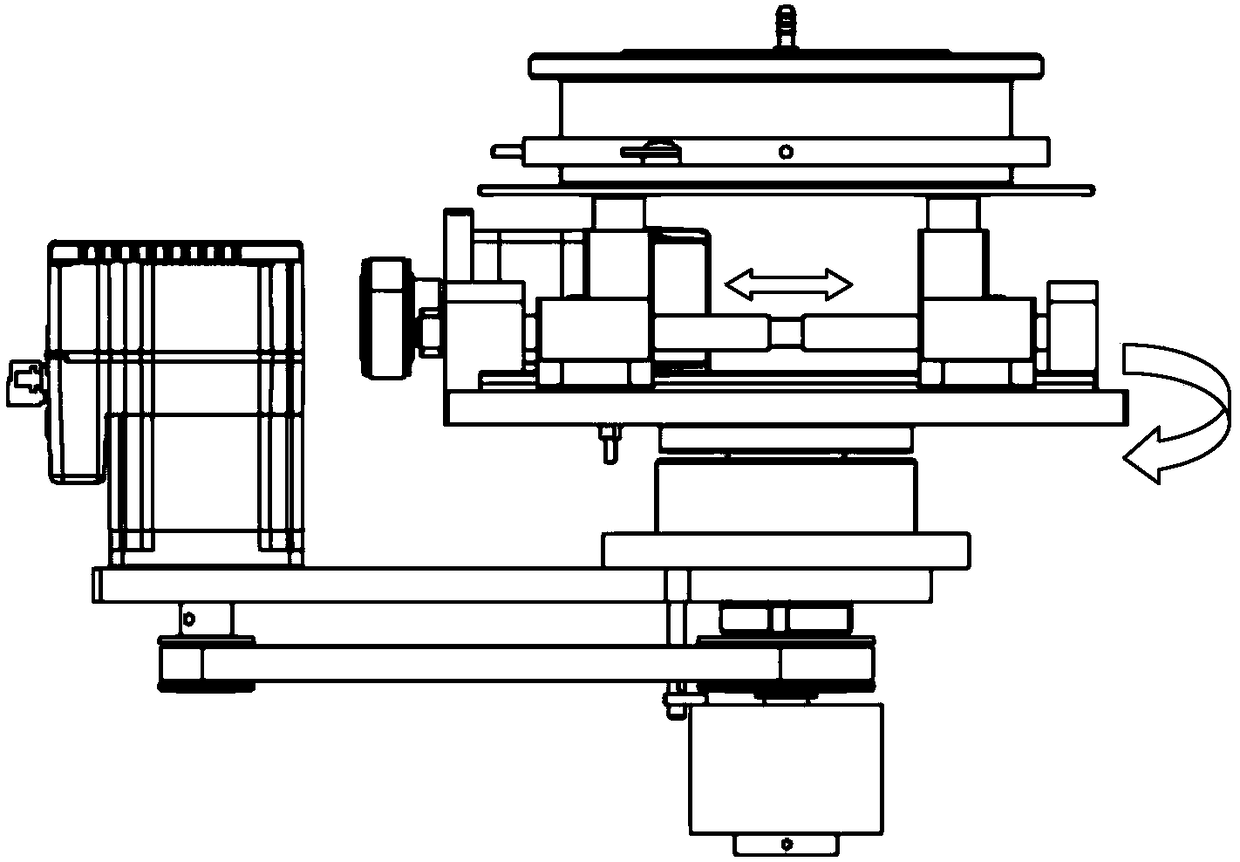

[0054] The full simulation chewing machine of the present invention is used to simulate the chewing process of gum-based chewing tobacco.

[0055] Put a piece of gum-based chewing tobacco into the solution dish, inject 10ml of artificial saliva, set the chewing mechanical teeth to rotate up and down for 20 times at a frequency of once every 5 seconds, start the left and right opening and closing rotating components every 4 times, Rotate 45° to do one bite, the bite width is 15mm, a total of 5 bites. After the extraction is completed, the solution is extracted to the No. 2 collection station. Inject 10ml of artificial saliva for the second time, rotate and chew 10 times at a frequency of once every 10 seconds, start the left and right opening and closing rotating components every 5 times, make a bite every 30° rotation, the bite width is 10mm, and bite 6 times in total. After completion, the solution is extracted to the No. 3 collection station. Inject 10ml of artificial sali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com