Illuminable loading device for rigidity testing of material and application method thereof

A loading device and rigid technology, applied in the direction of measuring devices, analyzing materials, strength characteristics, etc., can solve problems such as complicated maintenance work, difficulty in obtaining point performance at any time, measurement errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

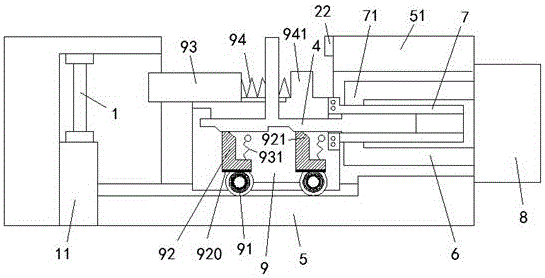

[0009] Combine below Figure 1-2 The embodiments of the present invention will be described in detail.

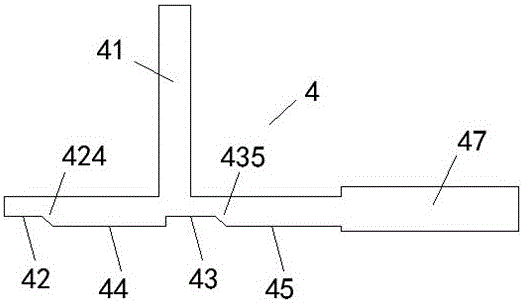

[0010] The illuminable loading device for material rigidity testing according to the embodiment includes a frame 5, a loading trolley 9 that can move left and right on the frame 5, and a device fixed at the left end of the frame 5 for clamping the workpiece 1. The clamping table 11, wherein the right side of the loading trolley 9 is fixedly connected with an external threaded sleeve 7 for extending into the hollow interior of the rotating shaft 6 and threadedly fitting with the internal threaded ring portion 71 at the left end of the rotating shaft 6, so The right end of the rotating shaft 6 is dynamically coupled with the output shaft of the drive motor 8 installed on the right side of the boss 51 of the frame 5, and the loading trolley 9 is equipped with two roller assemblies from left to right on the lower side 91. Each of the roller assemblies 91 includes a roller install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com