Quantum dot wide color gamut polyester film, brightness enhancement film and diffusion film for backlight module

A technology of backlight modules and quantum dots, which is applied in optics, optical components, instruments, etc., can solve the problem of low color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

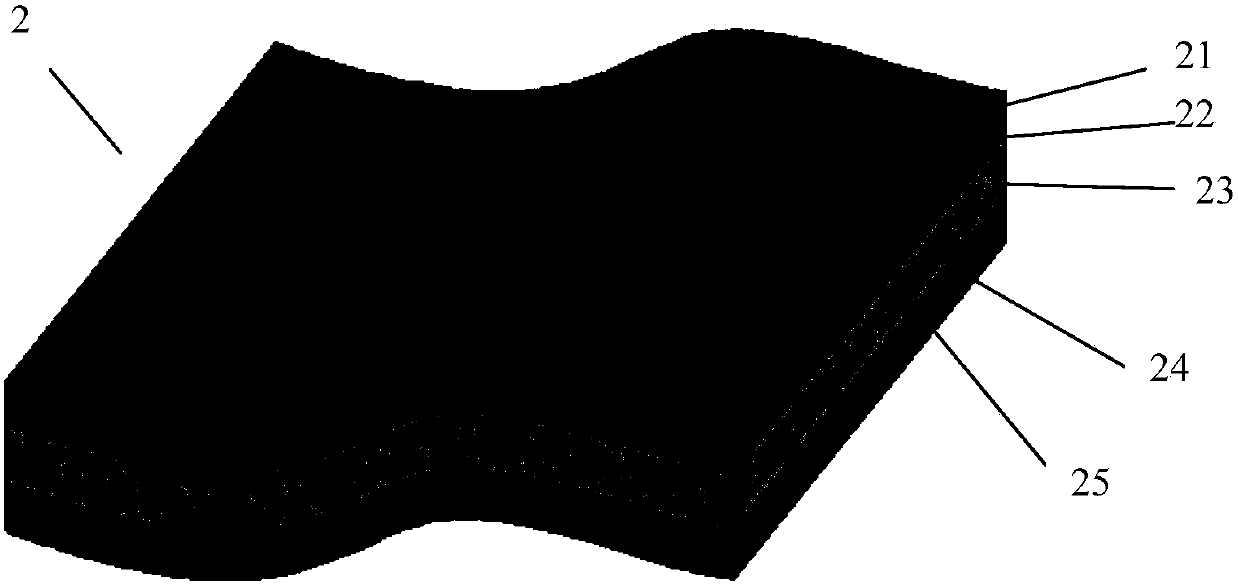

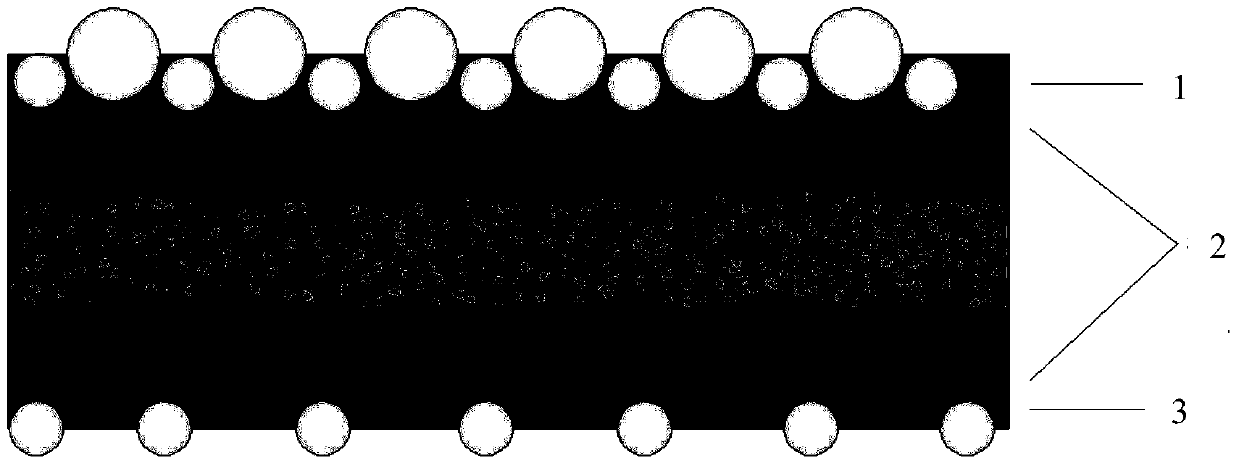

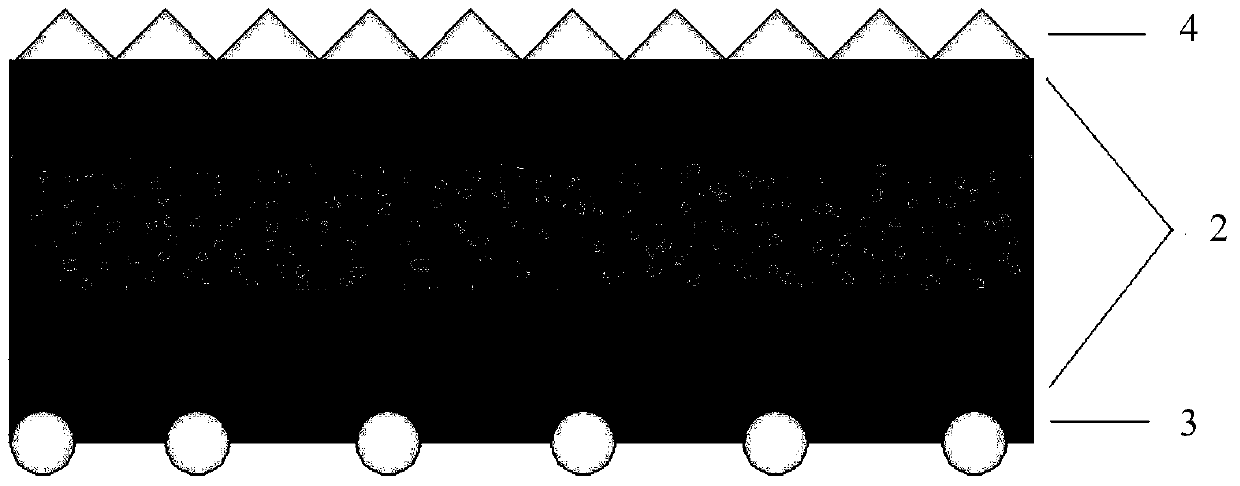

Embodiment 1

[0097] The present invention provides a wide color gamut brightness enhancement film, the brightness enhancement film includes a substrate layer and a brightness enhancement structure layer, the substrate layer is the quantum dot wide color gamut polyester film for backlight modules provided by the present invention, wherein , the proportion of layer A is 85% of bright polyester chips, 15% of anti-adhesion masterbatch, the thickness of layer A is 10 microns; the proportion of layer B is 70% of bright polyester chips, quantum dot masterbatch 30%, the content of quantum dot powder in the quantum dot masterbatch is 10%, the particle size of the red quantum dots in the quantum dot masterbatch is 6nm, the particle size of the green quantum dots is 2nm, and the weight ratio of red and green quantum dots is 2 : 5 (red: green), the thickness of layer B is 168 microns, and the total thickness of the finished product is 188 μm, wherein the barrier layer is a polyether polyurethane barrie...

Embodiment 2

[0101] The present invention provides a wide color gamut brightness enhancement film, the brightness enhancement film includes a substrate layer and a brightness enhancement structure layer, the substrate layer is the quantum dot wide color gamut polyester film for backlight modules provided by the present invention, wherein The proportion of layer A is 85% of bright polyester chips, 15% of anti-adhesion masterbatch, and the thickness of layer A is 10 microns; the proportion of layer B is 70% of bright polyester chips, 30% of quantum dot masterbatch %, the content of quantum dot powder in the quantum dot masterbatch is 10%, the particle size of the red quantum dots in the quantum dot masterbatch is 6nm, the particle size of the green quantum dots is 3nm, and the ratio of red and green quantum dots is 2:5 (red: green), the thickness of layer B is 168 microns, and the total thickness of the finished product is 188 μm, wherein the barrier layer is a polyether polyurethane barrier ...

Embodiment 3

[0105] The present invention provides a wide color gamut brightness enhancement film, the brightness enhancement film includes a substrate layer and a brightness enhancement structure layer, the substrate layer is the quantum dot wide color gamut polyester film for backlight modules provided by the present invention, wherein The proportion of layer A is 85% of bright polyester chips, 15% of anti-adhesion masterbatch, and the thickness of layer A is 10 microns; the proportion of layer B is 70% of bright polyester chips, 30% of quantum dot masterbatch %, the content of quantum dot powder in the quantum dot masterbatch is 10%, the red quantum dot particle diameter in the quantum dot masterbatch is 5nm, the green quantum dot particle diameter is 2.5nm, and the ratio of red and green quantum dots is 2: 5 (red: green), the thickness of layer B is 168 microns, and the total thickness of the finished product is 188 μm, wherein the barrier layer is a polyether polyurethane barrier layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com