Method and device for calculating temperature rise of metal parts overcurrent

A metal parts, overcurrent technology, applied in computing, electrical digital data processing, instruments, etc., can solve problems such as waste of resources and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

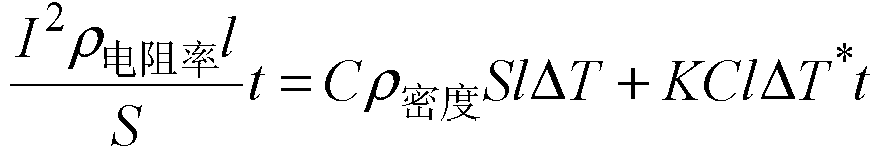

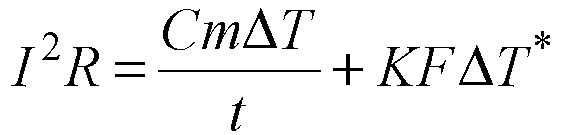

[0009] An embodiment of the present invention provides a method for calculating the temperature rise of the overcurrent of a metal part. The method is based on Joule's law, specific heat capacity formula and Newton's cooling law, combined with the law of conservation of energy, and determines the metal part through the determined relevant parameters about the metal part. The temperature rise of the component when the overcurrent occurs.

[0010] In this embodiment, according to the energy Q1 generated by the current passing through the conductor due to impedance (i.e. Joule's law), the heat energy Q2 transformed into a conductor (i.e. the specific heat capacity formula), and the energy Q3 lost by heat transfer of external substances (i.e. Newton's cooling law), we can obtain Come up with the following three equations:

[0011] Q 1 = I 2 Rt,

[0012] Q 2 = cmΔT,

[0013] Q 3 =KFΔT * t.

[0014] Among them, I is the current value passing through the metal part, R is the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap