Loader for rigidity testing of material and application method thereof

A loader, rigid technology, applied in the field of material testing equipment, can solve problems such as measurement errors, complicated maintenance work, and slight fluctuations in loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

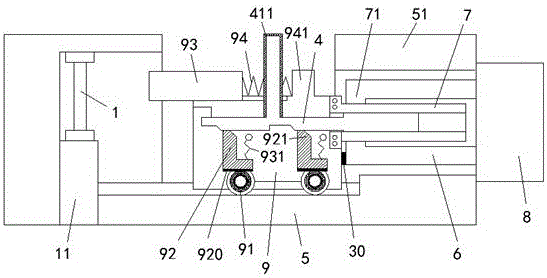

[0009] Combine below Figure 1-2 Embodiments of the present invention will be described in detail.

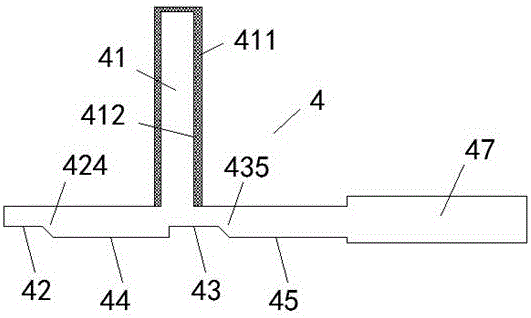

[0010] The loader for material rigidity testing according to the embodiment includes a frame 5, a loading trolley 9 capable of moving left and right on the frame 5, and a clamping table fixed at the left end of the frame 5 for clamping the workpiece 1 11, wherein, the right side of the loading trolley 9 is fixedly connected with an externally threaded sleeve 7 for extending into the hollow interior of the rotating shaft 6 and screwing with the internally threaded ring portion 71 at the left end of the rotating shaft 6, the rotating The right end of the shaft 6 is power-connected with the output shaft of the drive motor 8 installed on the right side of the boss 51 of the frame 5, and the lower side of the loading trolley 9 is equipped with two roller assemblies 91 from left to right, Each of the roller assemblies 91 includes a roller mounted by a one-way bearing and used to eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com