A Method for Analyzing the Residual Compressive Strength of Composite Materials After Impact Damage

A composite material, impact damage technology, used in instrumentation, computing, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Residual strength analysis of aircraft rudder composite laminates after impact damage.

[0036] 1 Aircraft Rudder Composite Laminate Information

[0037] Typical layup: (±45) / 0 2 / (0,90) / 0 / (±45) / 0 / (0,90) / 0 2 / (±45)

[0038] Thickness: 2.427mm

[0039] 2 Determine the impact energy and punch diameter

[0040] The impact object is a steel ball with a diameter of 12.7 mm, the mass of the impact object is 5.5 kg, and the impact energy is 4.45 J / mm.

[0041] 3 Establish impact damage calculation model

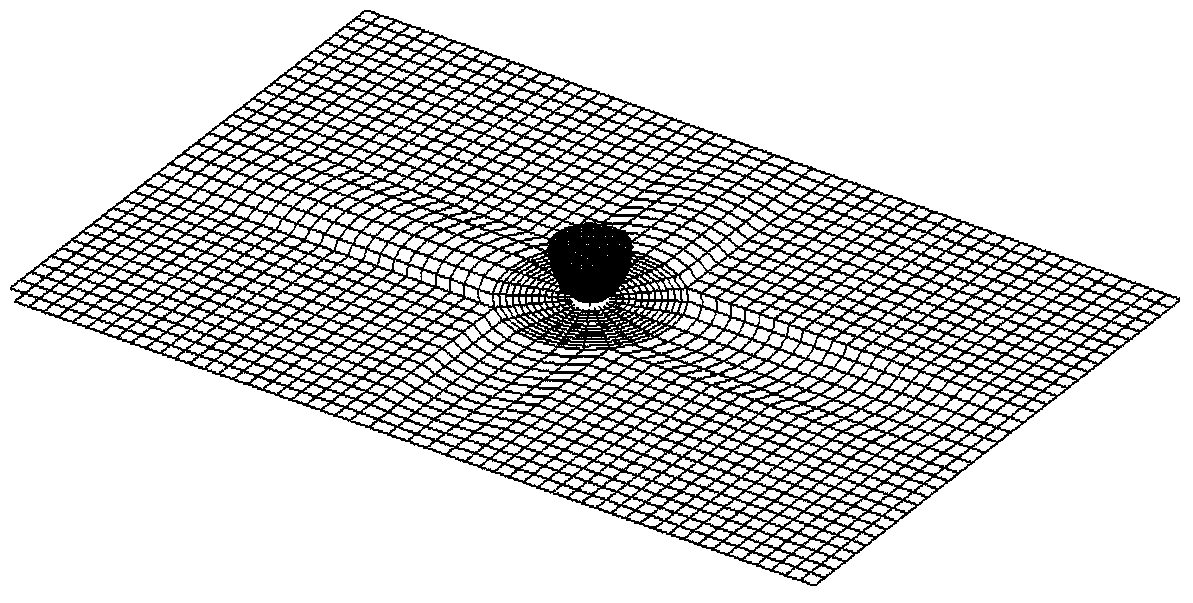

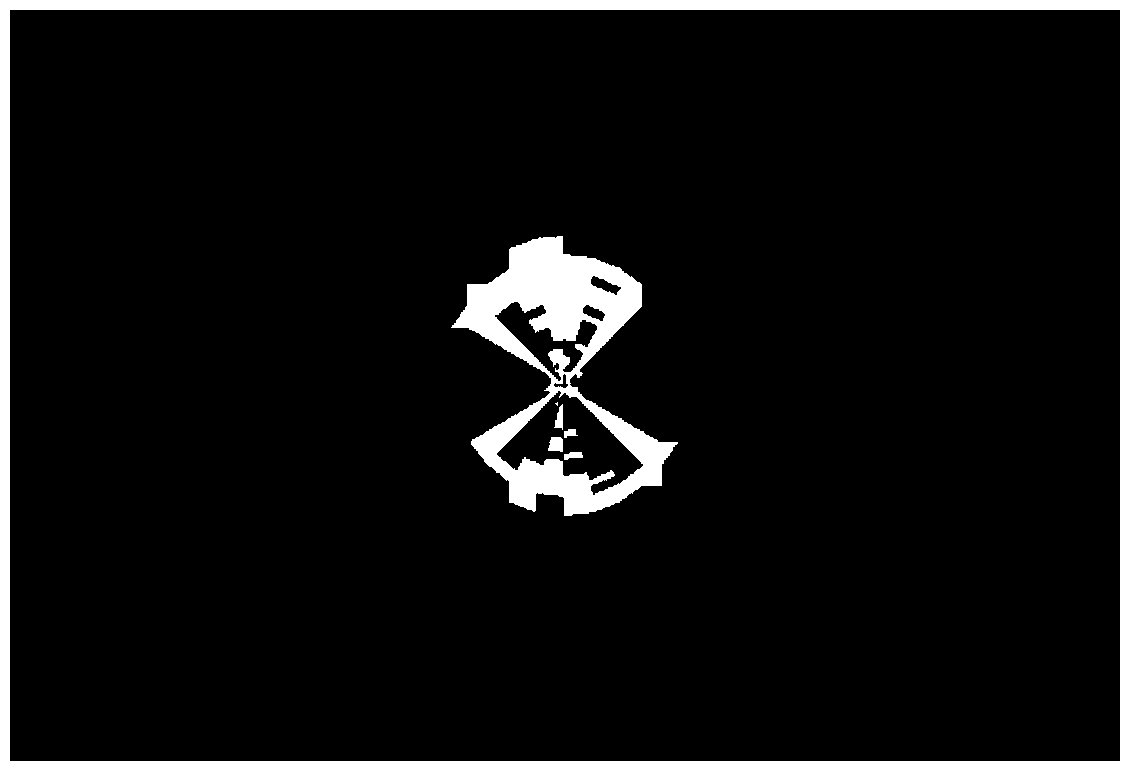

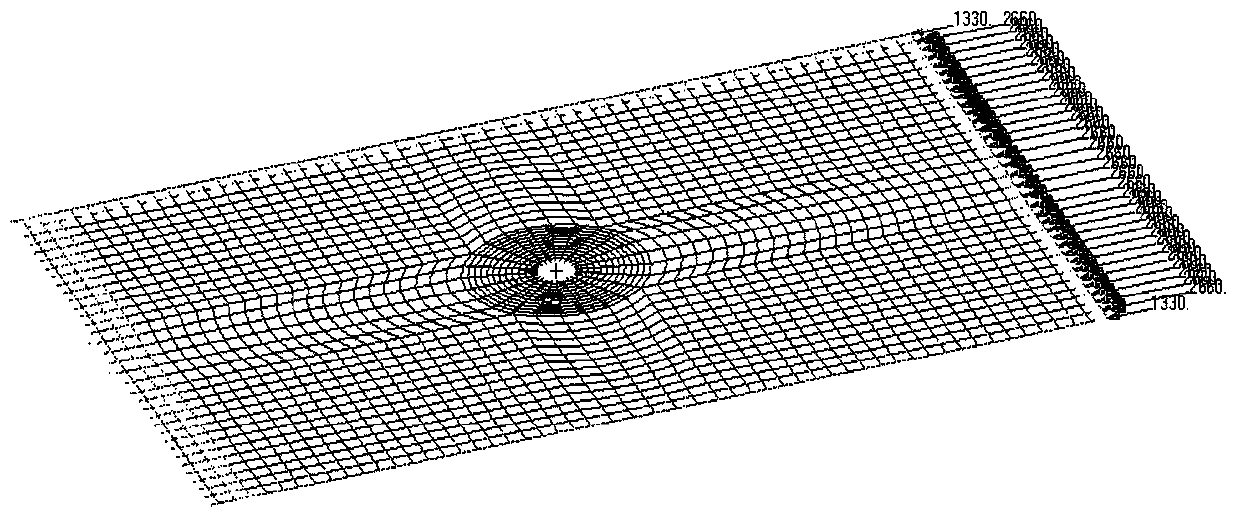

[0042] Such as figure 1 As shown, the size of the laminated plate is 150mm*100mm, and 4-node shell elements are used for simulation, and the impact object is simulated by rigid body elements. In order to improve the simulation accuracy, the mesh is refined in the impact center area. The laminate boundary is simply supported on four sides, with adaptive master-slave contact between the impact ball and the laminate. In order to comprehensively characterize the failure m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com