Processing tomato non-powered automatic flap double-layer transport car body

A technology for processing tomatoes and turning them automatically, which is applied to motor vehicles, transportation and packaging, and vehicles used for freight transportation, etc., can solve problems such as tomato crushing and damage, and achieve the effects of easy realization, cost saving and convenient transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

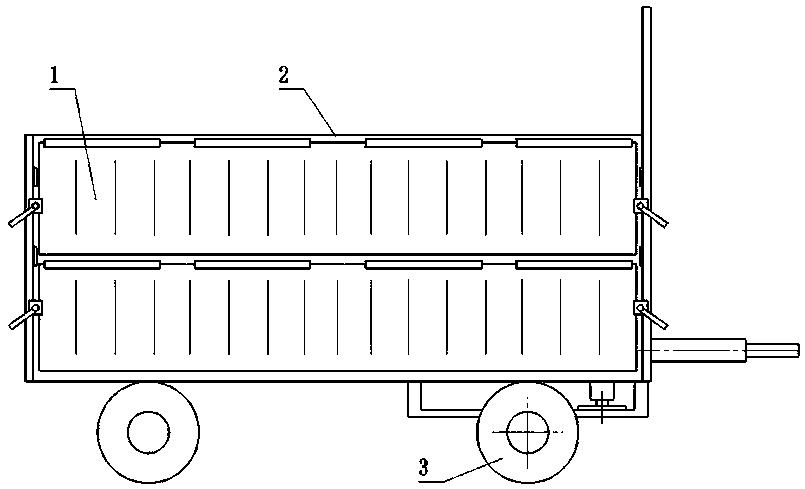

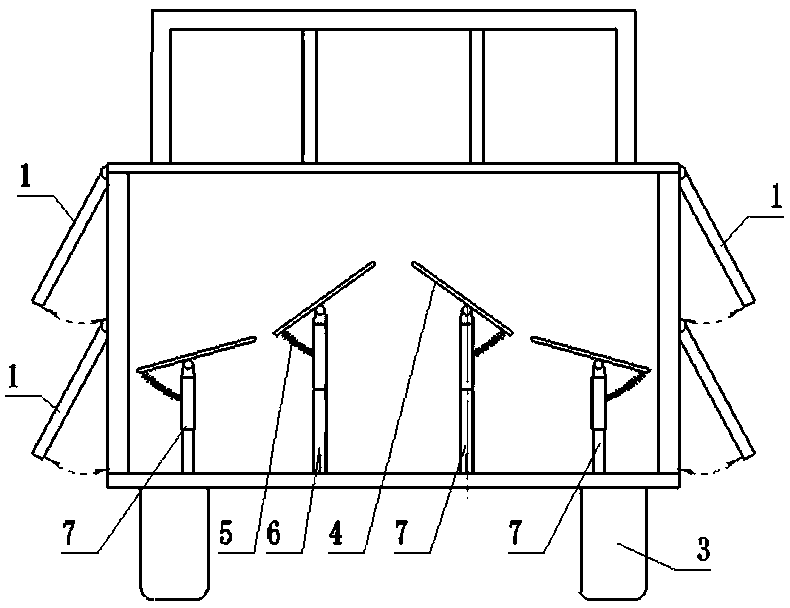

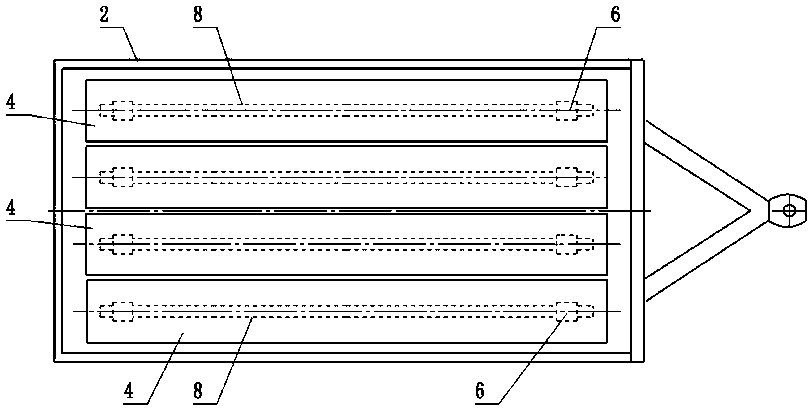

[0030] refer to figure 1 — Figure 4 , is a schematic structural diagram of Embodiment 1 of the present invention.

[0031] A two-layer transport vehicle body with no power and automatic flap for processing tomatoes, including a body box 2 and walking wheels 3, multiple sets of support plate assemblies 7 are arranged in the body box 2, and each set of support plate assemblies 7 includes front and rear Support legs 6 arranged in pairs, a longitudinal axis 8 is provided above the support legs 6, a support plate 4 is provided on the longitudinal axis 8, the support plate 4 is fixedly connected with the longitudinal axis 8, and the position of the fixed point is The support plate 4 is arranged eccentrically in the horizontal direction and close to the inner side of the bucket box body 2. The longitudinal axis 8 and the legs 6 are hinged so that the longitudinal axis 8 drives the support plate 4 to swing left and right with the legs 6 as the fulcrum. A swing amplitude limiting me...

Embodiment 2

[0037] refer to Figure 5 Compared with Embodiment 1, the difference of this embodiment is that the support leg 6 is a liftable structure, specifically: the upper end of the upper sleeve 11 is hinged to the longitudinal axis 8, and the diameter of the lower sleeve 12 is smaller than that of the upper sleeve. 11, the lower sleeve 12 is inserted into the upper sleeve 11 from below, and the lower part of the upper sleeve 11 is connected to the bottom of the lower sleeve 12 through the compression spring 10; One side is provided with counterweight 13.

Embodiment 3

[0039] Compared with Embodiment 2, the difference of this embodiment is that the inside of the box body 2 is horizontally provided with a cross bar 9 for the support plate 4 to turn over and limit, and the cross bar 9 is located between the support plate 4 and the longitudinal axis. 8 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com