Novel logistics trolley

A logistics and trolley technology, which is applied in the direction of trolleys, multi-axis trolleys, trolley accessories, etc., can solve the problems of excessive weight, damage to the trolley, and the maximum weight limit placed on the logistics trolley, so as to achieve good shock absorption and buffering performance, avoiding the effect of placing too much weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

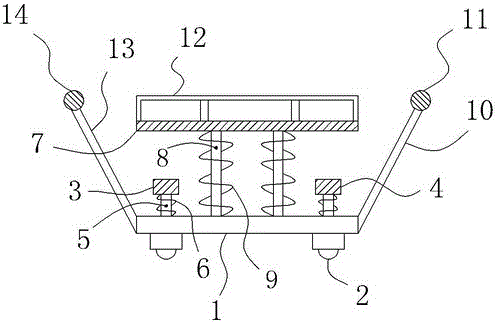

[0013] Such as figure 1 As shown, a new type of logistics trolley includes a base 1 and a walking wheel 2 located at the bottom of the base 1, and a left support plate 3 and a right support plate 4 are respectively arranged above the base 1, and the left support plate 3 and the base 1 and between the right support plate 4 and the base 1 are also connected with a plurality of vertically arranged bottom telescopic rods 5, and at the same time, a bottom coil spring 6 is also sleeved outside the bottom telescopic rod 5; A top plate 7 is also provided above the right support plate 4, and a plurality of vertically arranged top telescopic rods 8 are also connected between the top board 7 and the base 1, and top coil springs are also sleeved outside the top telescopic rods 8. 9. A plurality of top plate through holes are evenly opened on the top plate 7, and a first front strut 10 and a first rear strut are respectively provided on the right front end and the right rear end of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com