Powder impact pressure forming machine

A technology of impact pressure and molding machines, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., and can solve the problems of increased manufacturing costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings.

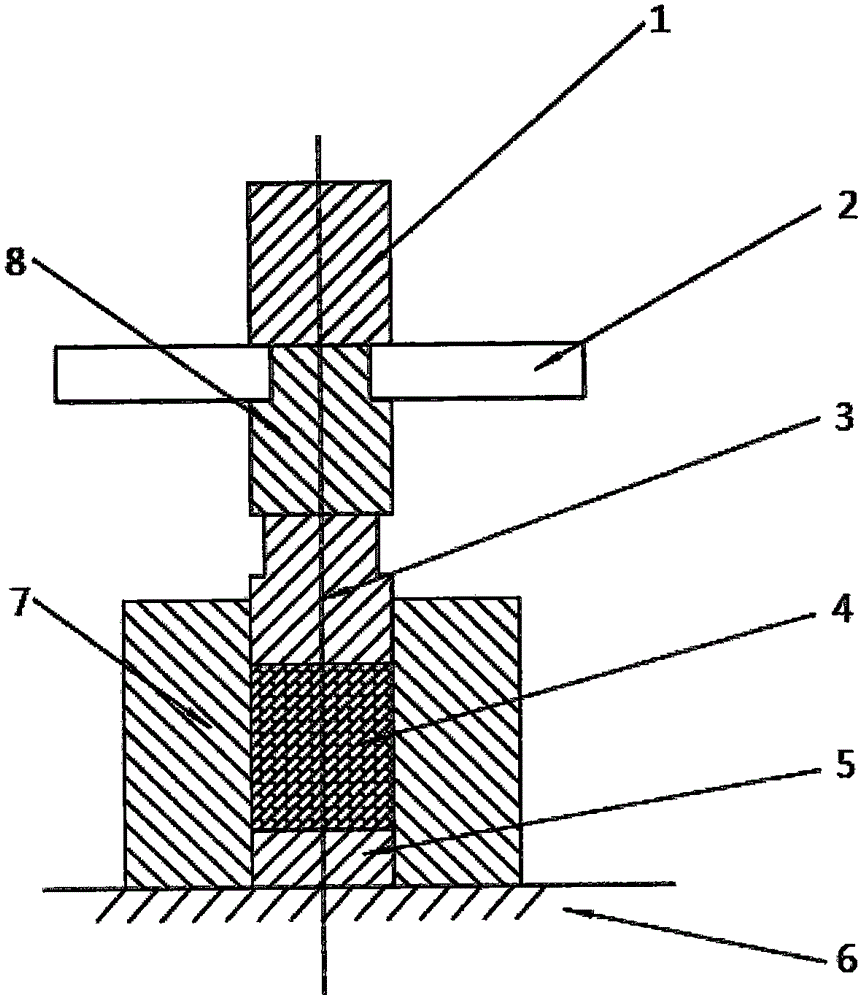

[0016] See figure 1 .

[0017] A powder impact pressure molding machine, a hydraulic or pneumatic impact device and a static pressure device are provided on the punch head 8, and the impact device (including a hydraulic or pneumatic punch head 1) is installed above the hydraulic static pressure die frame 2, and is connected with The static pressure device operates at the same time. The impact direction of the impact device is the same as the pressure direction of the static pressure device. The impact device and the static pressure device operate at the same time. The impact force, impact frequency and time can be adjusted separately. independent adjustment.

[0018] When the present invention works, the mold 7 is fixed on the base 6, the cushion block 5 is arranged on the bottom of the mold 7, and the product workpiece 4 is fixe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap