Lead acid battery having a strap molding well

A lead-acid battery, with mold technology, applied in the direction of lead-acid battery, lead-acid battery construction, battery pack components, etc., can solve the problems of increasing manufacturing steps, production costs, restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

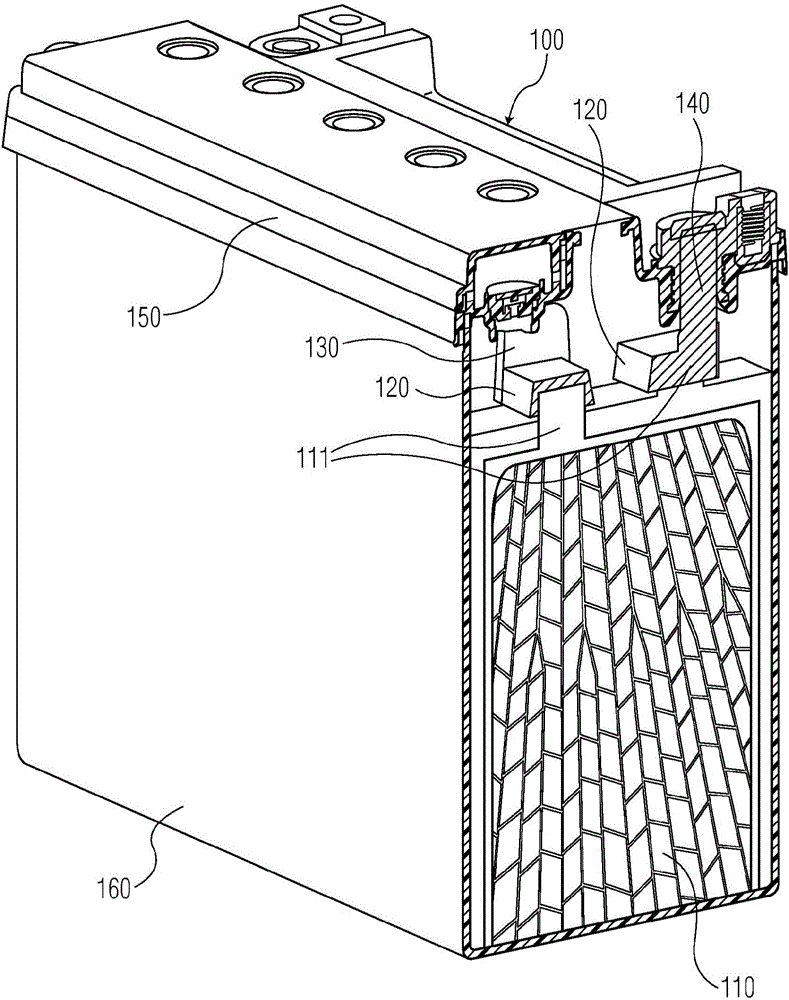

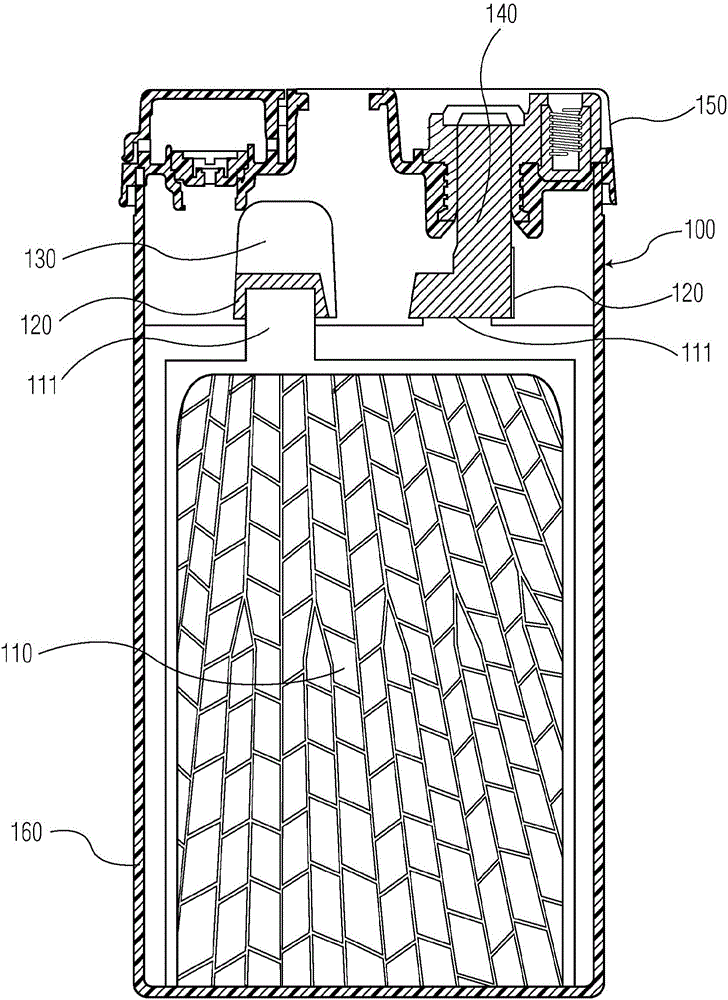

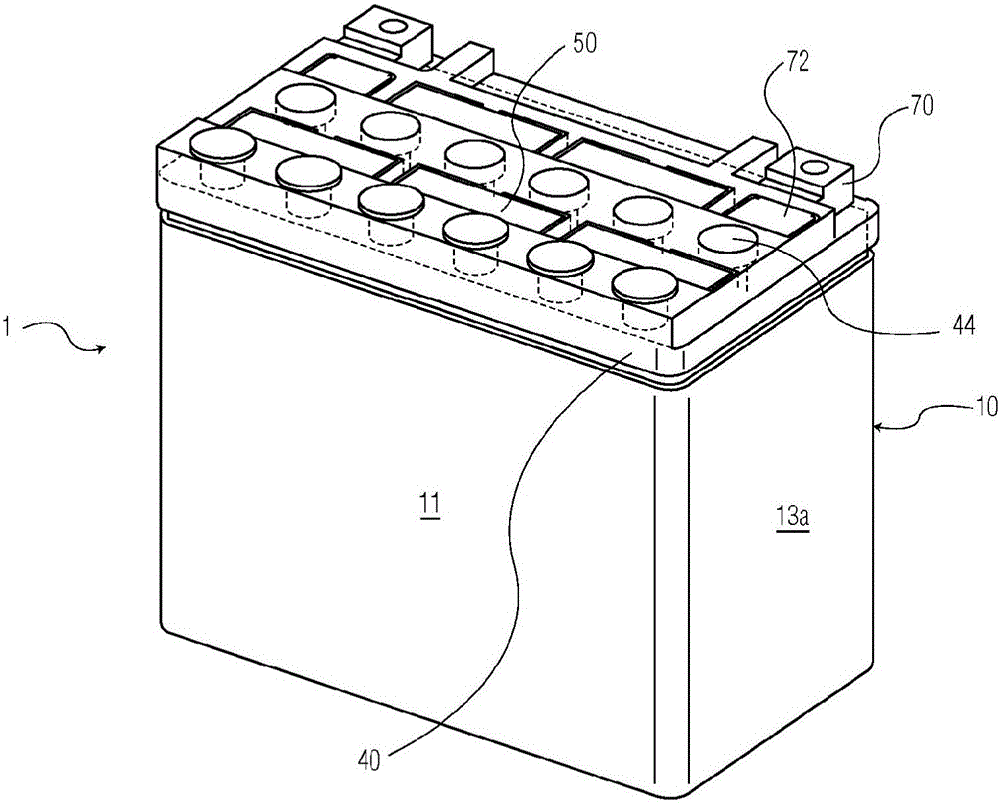

[0022] exist Figure 3-7 The embodiment of the lead-acid battery 1 shown in and 9-10 has a housing 10 , at least one battery plate unit 20 , a mold 30 , a cover 40 , a lead strap 50 , a manifold 60 and a terminal post 70 .

[0023] The housing 10 is a box-shaped container having a front wall 11 , a rear wall 12 , first and second side walls 13 a , 13 b , and a bottom wall 14 . In one embodiment, the length and height of the front wall 11 and the rear wall 12 are approximately equal. In another embodiment, the length and height of the first side wall 13a and the second side wall 13b are substantially equal. The width of the bottom wall 14 is approximately equal to the length of the side walls 13a, 13b. The length of the bottom wall 14 is substantially equal to the lengths of the front wall 11 and the rear wall 12 . The height of the side walls 13a, 13b is approximately equal to the height of the front wall 11 and the height of the rear wall 12 . The inside of the casing 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com