Take-up lever locking mechanism and embroidery machine

A technology of locking mechanism and thread take-up lever, which is applied in the field of embroidery machines and can solve problems such as no practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

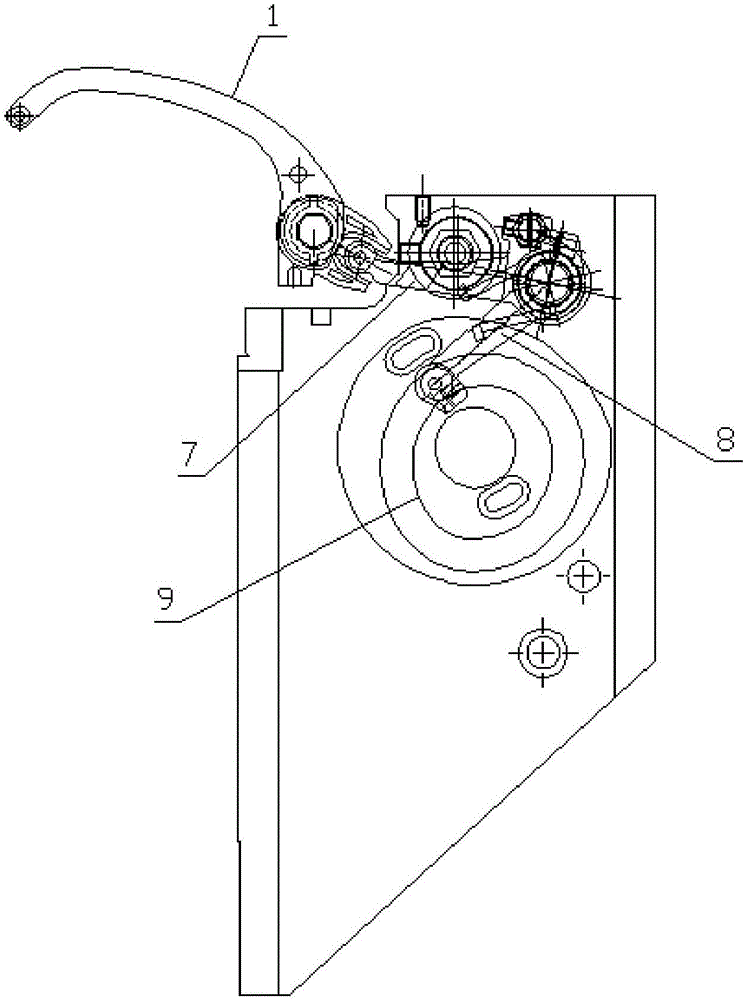

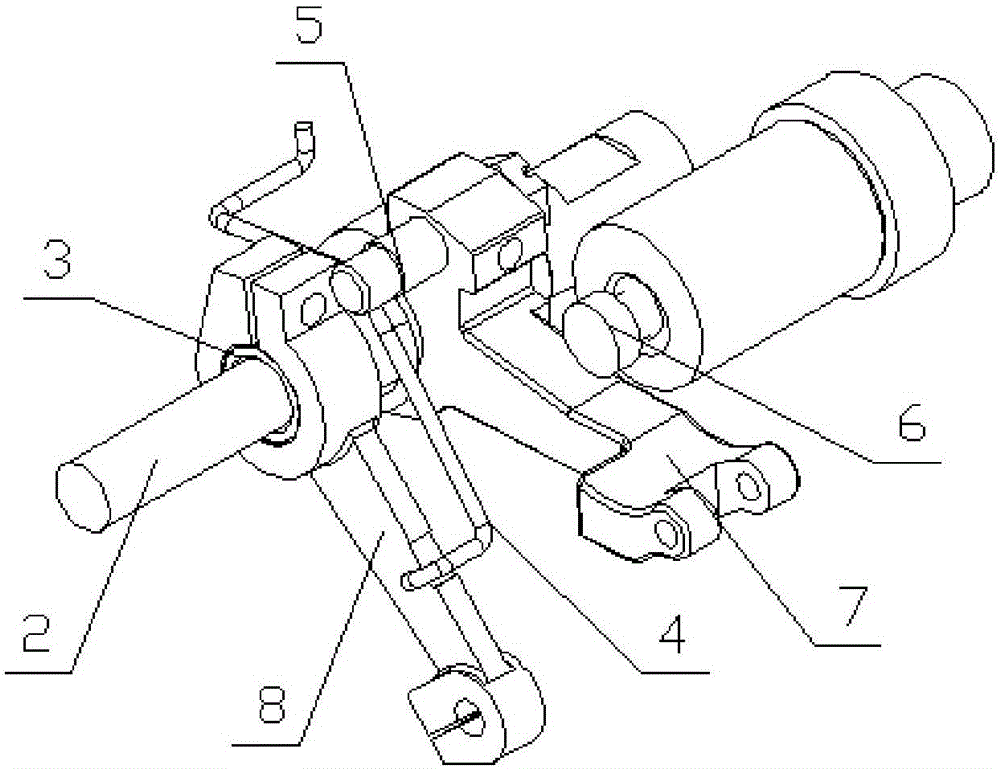

[0015] Example 1, such as figure 1 with figure 2 As shown, a thread take-up lever locking mechanism includes a main shaft mounted on a machine head housing, a thread take-up cam 9, a thread take-up A7, a thread take-up B8, and a thread take-up lever 1. The thread take-up cam 9 is mounted on the main shaft The thread take-up B8 is driven by the thread take-up cam 9. The end of the thread take-up B8 is provided with a roller, and the roller is embedded in the cam groove of the thread take-up cam 9, and the thread take-up A7 is driven by the thread take-up cam 9. The thread B8 drives and drives the thread take-up lever 1 to move.

[0016] Among them, the thread take-up A7 and the thread take-up B8 are not locked, and the thread take-up A7 and the thread take-up B8 are rotated and nested on the thread take-up sleeve 3. Therefore, the thread take-up A7 and the thread take-up B8 can be combined with the thread take-up sleeve 3. Turn each other. The thread take-up sleeve 3 is install...

Embodiment 2

[0019] Embodiment 2, an embroidery machine, is equipped with the thread take-up lever locking mechanism described above.

[0020] With the traditional structure, when the color is changed, the needle bar does not lower the needle, and the thread take-up lever makes an empty stroke, which will cause an empty pull of the upper thread. Because the upper thread is not consumed in this round of the thread take-up lever, the upper thread is lowered. The tension of the needle thread is not tight enough, which affects the quality of high-end embroidery. When a certain needle position is broken and the thread needs to be mended, the existing machine uses the needle bar of the mending needle position to move, while the needle bars of other needle positions are stationary, but the thread take-up levers of all needle positions are moving. This causes the empty stroke of the thread take-up levers of other needle positions, which affects the quality of the next needle embroidery of all other n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com