Drop test machine for exterior decorating product of automobile

A technology of drop test and exterior decoration, applied in the field of machinery, to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

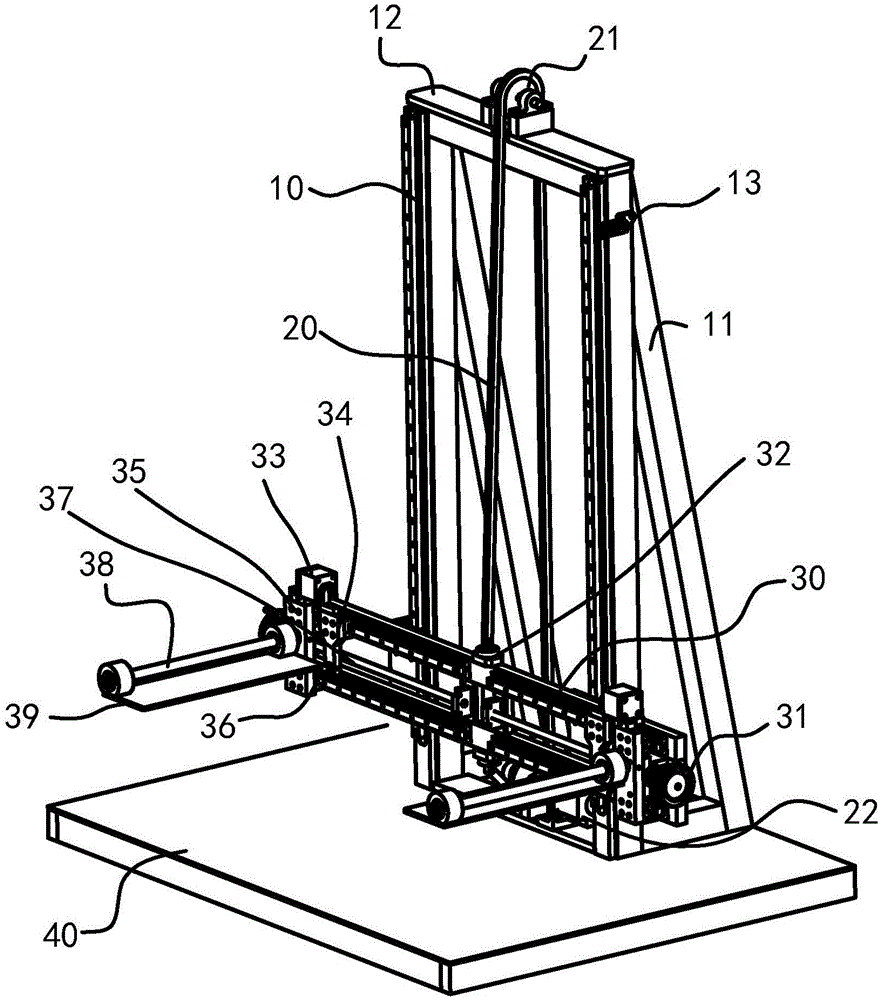

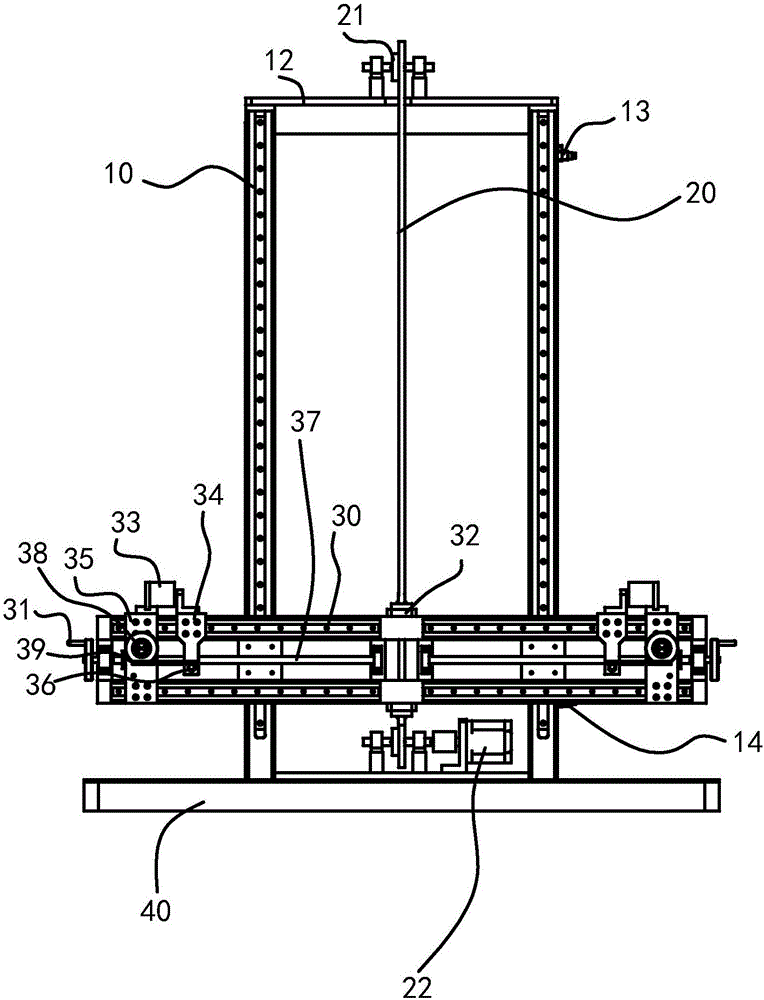

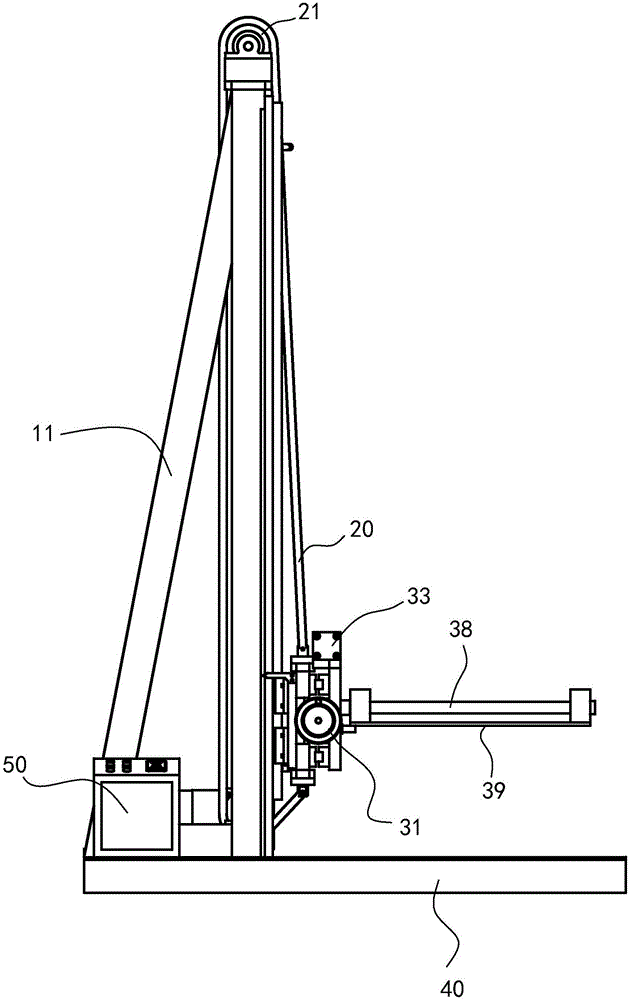

[0027] Such as Figure 1 to Figure 4 As shown, the present invention provides a drop tester for automotive exterior trim products, including a first guide rail 10 arranged vertically; Sliding, the falling mechanism is provided with a supporting plate 39;

[0028] The driving mechanism is used to drive the drop mechanism to slide up and down along the first guide rail 10 ; the controller is used to control the driving mechanism and the pallet 39 to work.

[0029] When the present invention is used in work, the test product is placed on the supporting plate 39, the control controller makes the drive mechanism work, and the drive mechanism drives the drop mechanism to rise to the rated drop height, so that the test product i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com