LED display calibration method

A technology of LED display and calibration method, applied in static indicators, instruments, etc., can solve the problems of inability to solve the problem of bright and dark lines, difficulty in ensuring the stability of the adjustment effect, and dependence on operator experience, so as to eliminate the problem of splicing bright and dark lines. , Eliminate the problem of split screen splicing line, and avoid the effect of manually adjusting the splicing line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

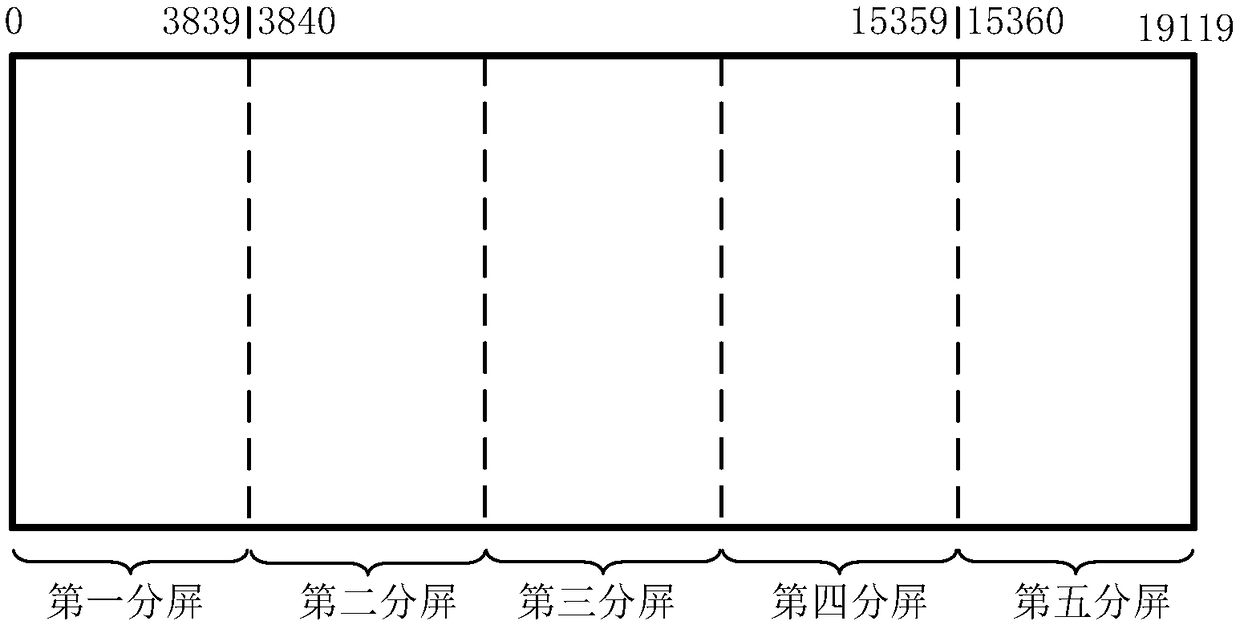

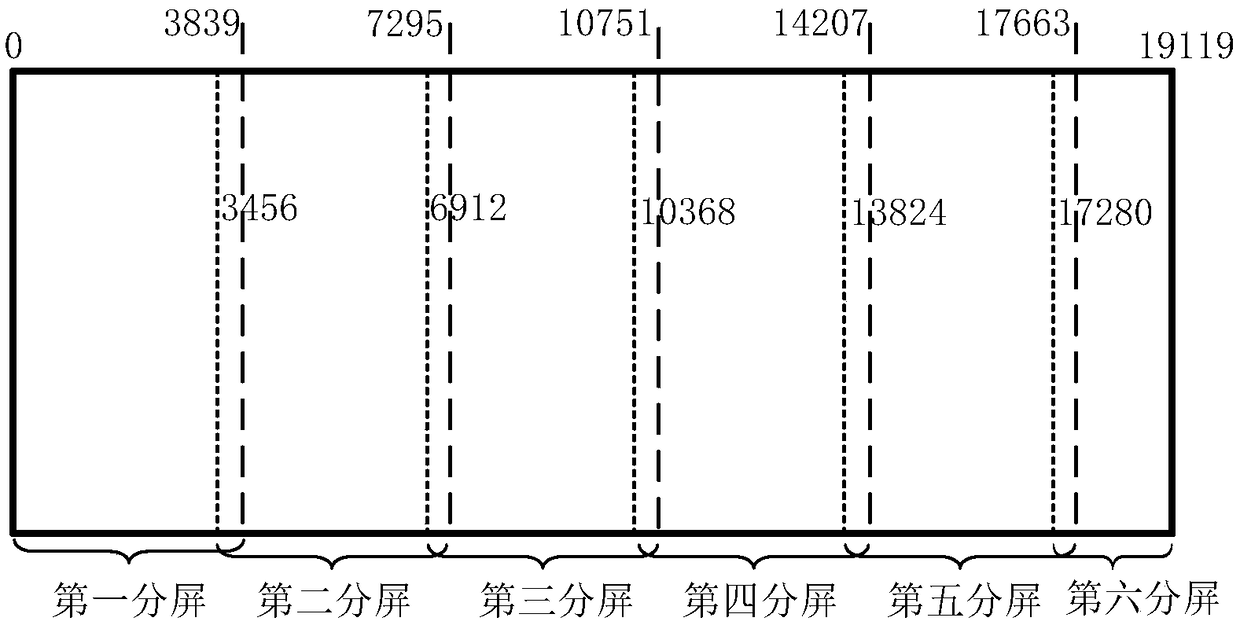

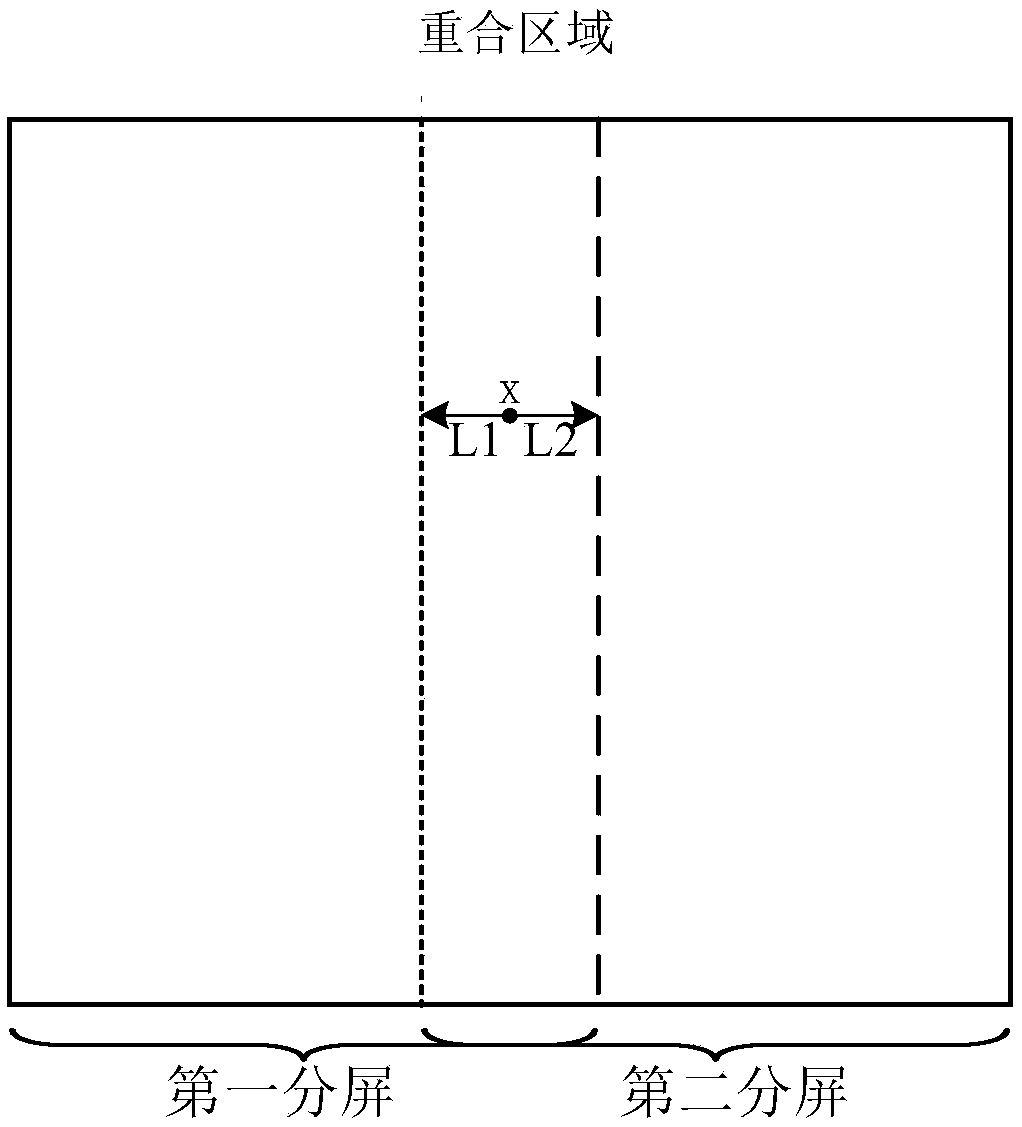

[0024] Specifically, the following embodiments of the present invention propose a new solution for correcting bright and dark lines between sub-screens of super-large LED display screens, including the step of splitting the screen and the step of compensating the difference in brightness and chromaticity between the sub-screens; Eliminate split-screen splicing line problems caused by inconsistent data distribution trends between split screens, effectively alleviate or even eliminate splicing light and dark line problems caused by physical splicing between split screens, and avoid manual adjustment of splicing by on-site calibration personnel line or set up the camera for partial recalibration.

[0025] In the following, the resolution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com