Revolution speed detection device

A detection device and technology of rotation speed, which is applied in the direction of measurement device, linear/angular velocity measurement, speed/acceleration/impact measurement, etc., and can solve the problem that the rotation detection wheel affects the detection results and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

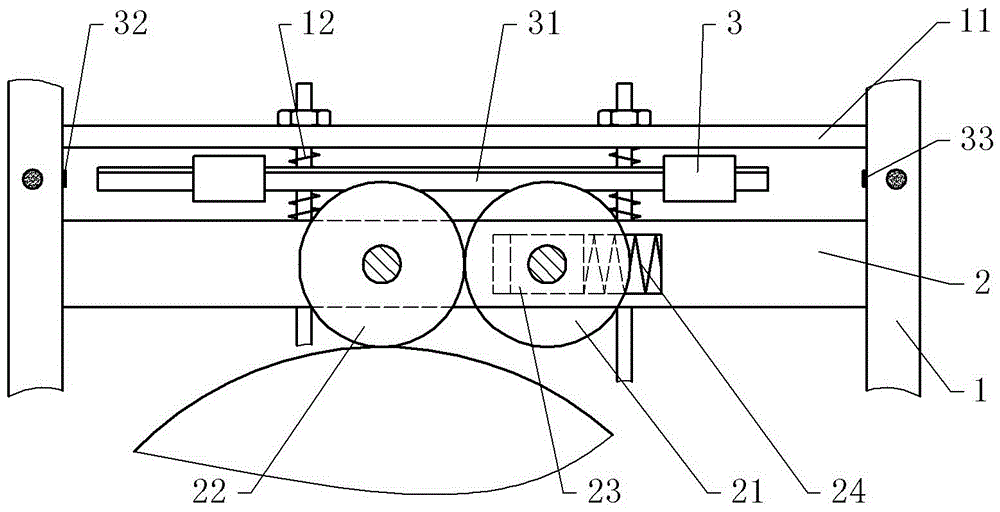

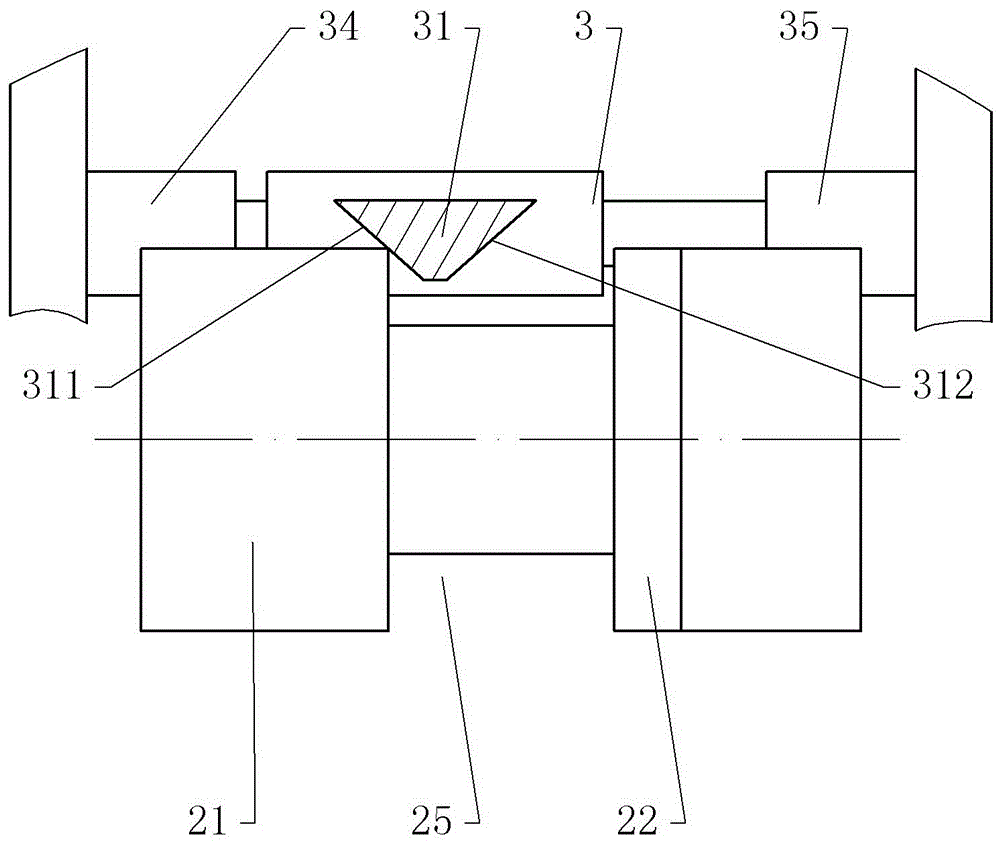

[0021] The reference numerals in the drawings of the description include: bracket 1, adjusting pressure plate 11, first spring 12, mounting seat 2, first roller 21, second roller 22, slider 23, second spring 24, annular groove 25, Slide seat 3 , slide bar 31 , first control switch 32 , second control switch 33 , second cylinder 34 , first cylinder 35 , first contact surface 311 , second contact surface 312 .

[0022] The embodiment is basically as figure 1 , figure 2 , image 3 Shown:

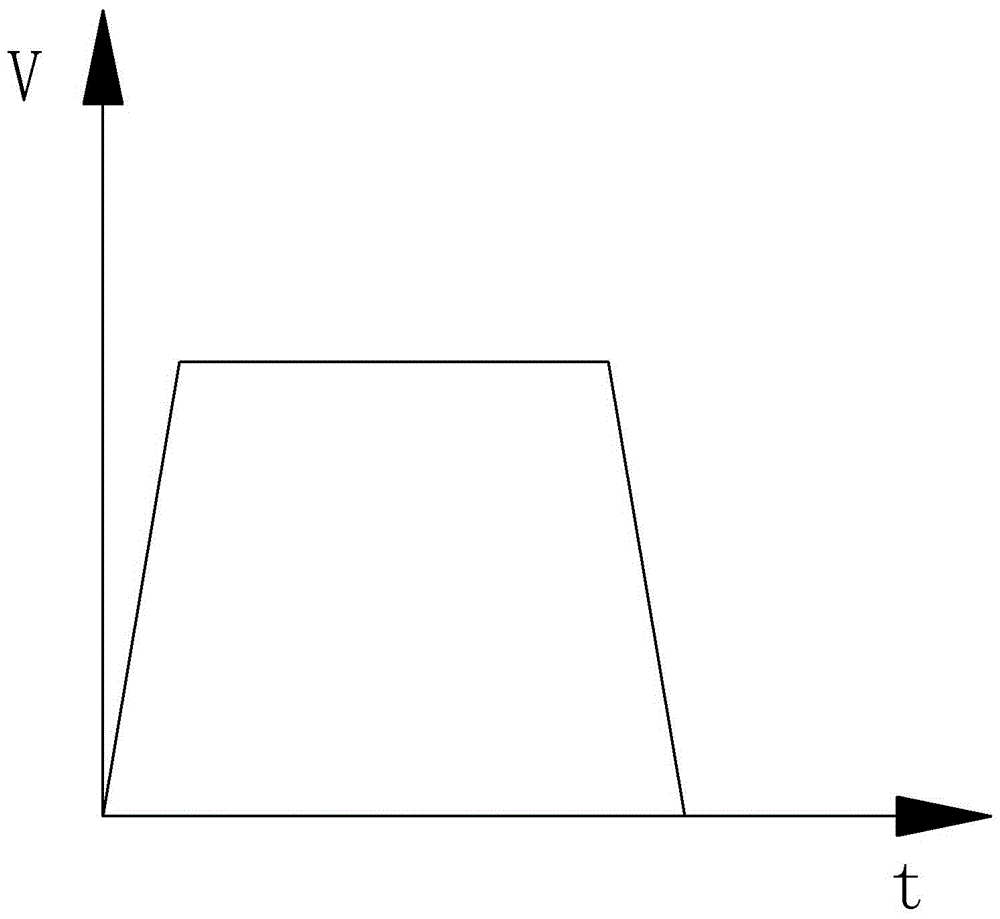

[0023] The rotation speed detecting device of the present embodiment includes a bracket 1, a rolling part, a sliding part, a counting part and a display screen; the rolling part includes a mounting seat 2, a slider 23, a first roller 21 and a second roller 22; the sliding part includes a sliding seat 3 and a sliding bar 31; the counting part includes a distance sensor and an encoder; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com