A kind of 3d printing equipment and method

A 3D printing and equipment technology, applied in the field of 3D printing, can solve the problems of liquid level fluctuation, low speed, complex machinery, etc., to achieve the effect of overcoming the liquid level fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

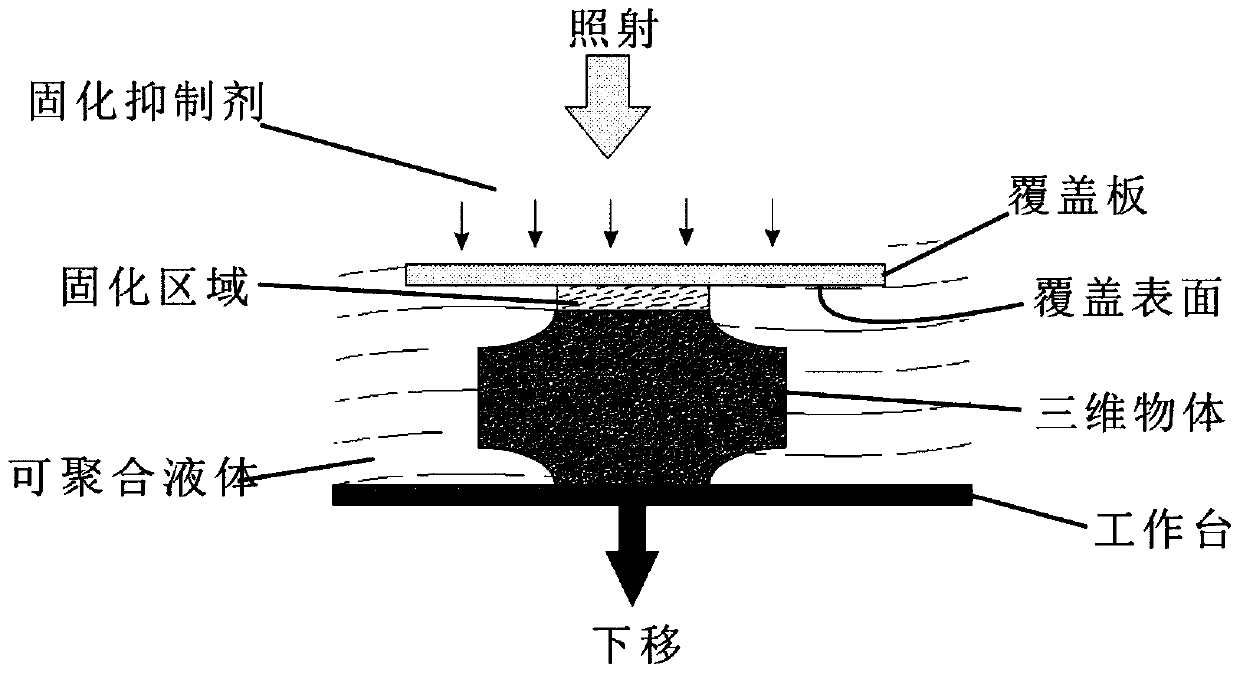

[0042] The present invention provides a method of 3D printing, such as figure 1 shown. In this method, the polymerizable liquid is irradiated by an irradiation source such as visible light or ultraviolet light to induce the solidification of the polymerizable liquid to produce a three-dimensional object. The method is implemented "top-down" with the irradiation source and consists of the following steps:

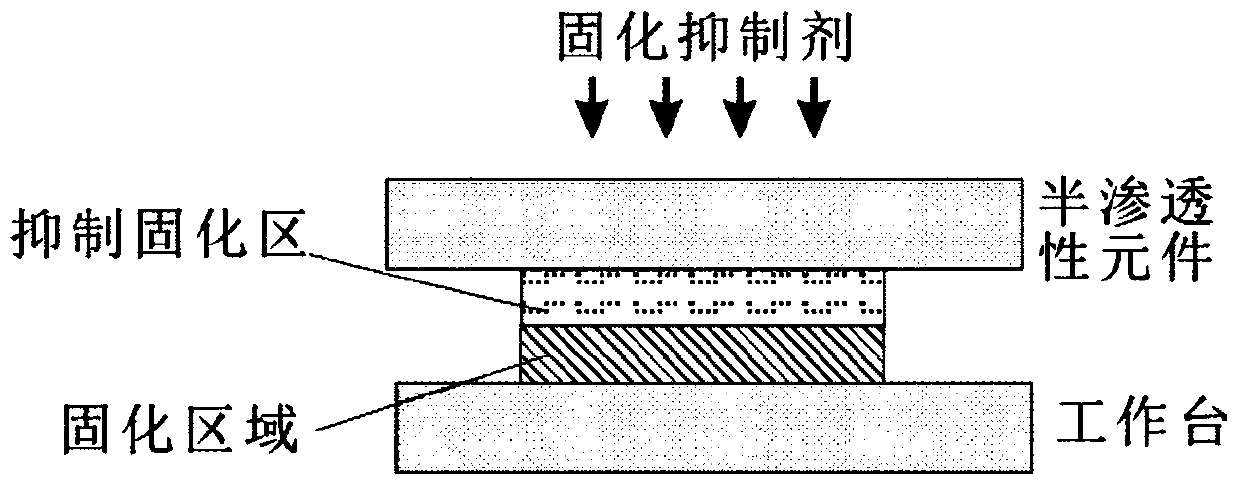

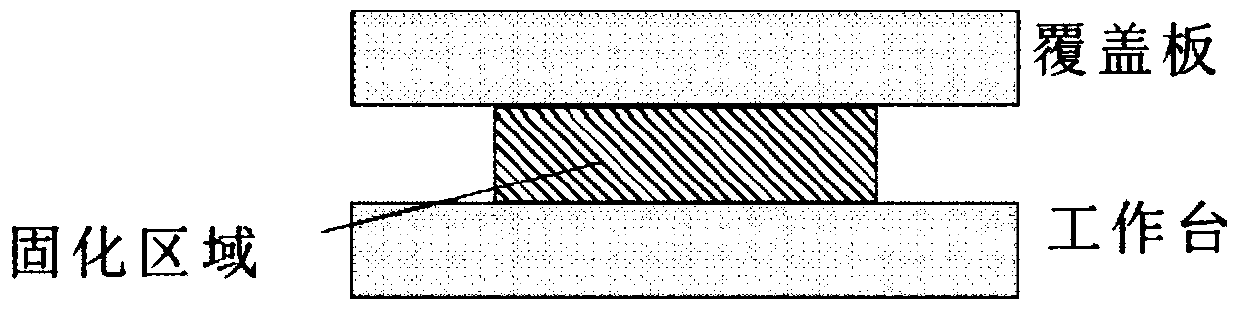

[0043] (a) Provide a workbench and a cover plate, wherein the cover plate is a component with a cover surface that is transparent to the radiation source, and a construction area for a three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com