A device for rapidly detecting the muscle development status of sheep or cattle and its application method

A cattle muscle and fast technology, applied in the field of cattle and sheep muscle quality testing, can solve the problems of ununiform stroking standards, difficulty in forming consensus points, and inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

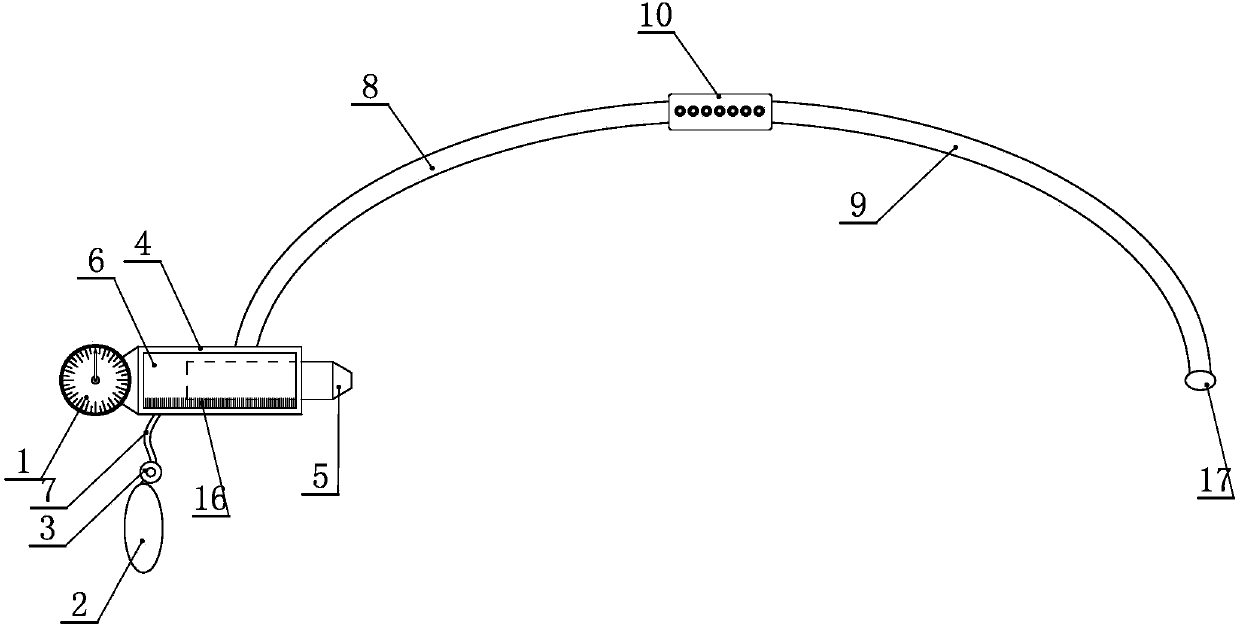

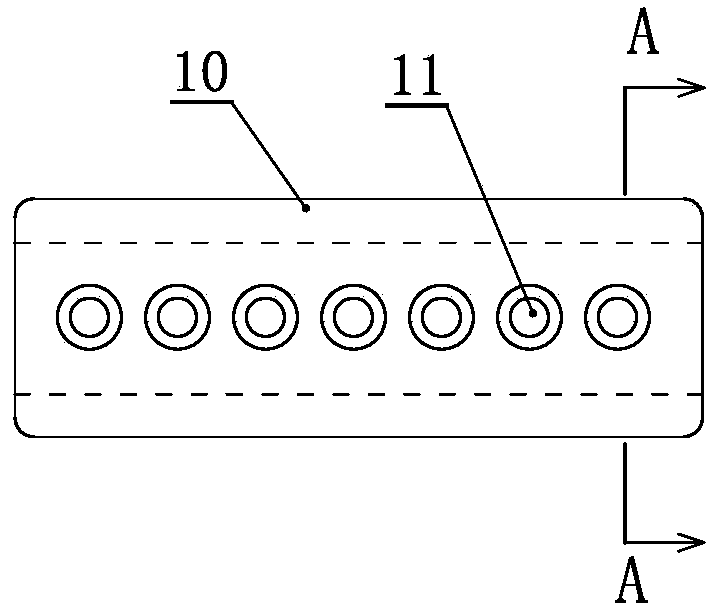

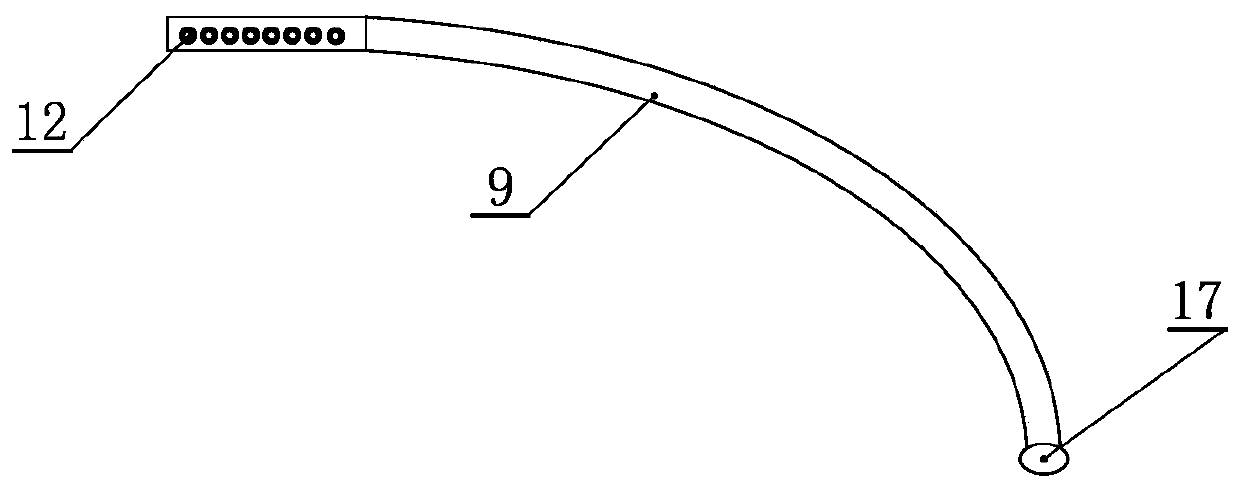

[0036] Embodiment one: if Figure 1-Figure 6 As shown, the invention includes a fixed frame, a pressure gauge 1, a pressure ball 2, a pressure ball switch valve 3, a pressure sleeve 4 and a pressure probe 5. The fixed frame is a curved deformable frame, and the fixed frame is fixed on the buttocks of a sheep or a cow. One end of the fixed frame is fixed on the pressure sleeve, and the other end is a free end. The inner cavity of the pressure jacket is a cavity 6, the non-detection end of the pressure probe extends into the pressure jacket 4, the pressure probe 5 is sealed and matched with the pressure jacket, the detection end of the pressure probe is located outside the pressure jacket and opposite to the free end of the fixing frame, the pressure The probe can move along the cavity under the action of cavity pressure. The pressure ball 2 is sealed and connected with the cavity of the pressure sleeve through the vent pipe 7, and a pressure ball switch valve is arranged on th...

Embodiment 2

[0039] Embodiment two: if Figure 7-Figure 12 As shown, the invention includes a fixed frame, a pressure gauge 1, a pressure ball 2, a pressure ball switch valve 3, a pressure sleeve 4 and a pressure probe 5. The fixed frame is a curved deformable frame, and the fixed frame is fixed on the buttocks of a sheep or a cow. One end of the fixed frame is fixed on the pressure sleeve, and the other end is a free end. The inner cavity of the pressure jacket is a cavity 6, the non-detection end of the pressure probe extends into the pressure jacket 4, the pressure probe 5 is sealed and matched with the pressure jacket, the detection end of the pressure probe is located outside the pressure jacket and opposite to the free end of the fixing frame, the pressure The probe can move along the cavity under the action of cavity pressure. The pressure ball 2 is sealed and connected with the cavity of the pressure sleeve through the vent pipe 7, and a pressure ball switch valve is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com