Pull back swing arm type short-circuit grounding clamp and grounding and disassembly method

A short-circuit grounding wire and swing arm technology, which is applied in the direction of connection, circuit, conductive connection, etc., can solve the problems of difficult installation of grounding wires, inability to install directly, and ineffective effects, and achieve the effect of avoiding electric shock hazards and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

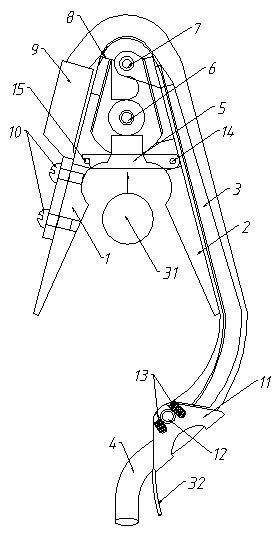

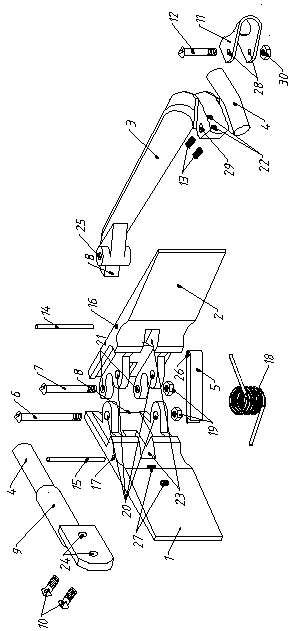

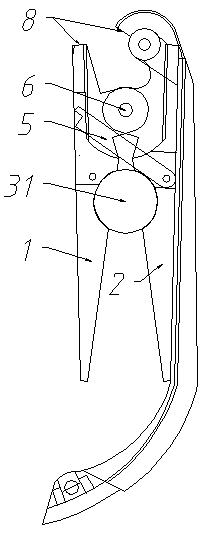

[0018] A pullback swing arm type short-circuit grounding clamp, which consists of: a left splint 1, a right splint 2, a pullback swing arm 3, a push rod 5, a U-shaped pressure plate 11 and a torsion spring 18, and the right Clamping plate 2 installs a described pull-back swing arm 3 additionally by bolt 2 7, and described pull-back swing arm 3 one end is provided with swing arm shaft hole 25 and card surface 8, and the other end is provided with swing arm head hole 29, two A lock nut hole 22 and a U-shaped pressing plate 11, the pull-back swing arm 3 is a J-shaped metal component, the outside is provided with an arc-shaped groove, and the bolt 16 penetrates into the hole 20 on the left and side splints, Then penetrate the torsion spring 18, and then penetrate the lower hole 20 of the clamping plate to tighten the nut one 19, and the bolt two 7 penetrates the hole 21 on the right side clamping plate, and then penetrates the 3 axis holes 25 of the pull-back swing arm, Then penet...

Embodiment 2

[0020] According to the grounding method of pulling back the swing arm type short-circuit grounding clamp described in embodiment 1, the method includes the following steps:

[0021] (1) When installing the grounding wire: pull down the grounding wire 4 or the insulating rope 32 and the wire 31 will move upwards and hit the ejector rod 5, and the ejector rod 5 will swing upward around the ejector rod shaft 14 and break away from the support. The left splint 1 and the right The side splint 2 rotates around the bolt one 6 under the elastic force of the torsion spring 18 to release the elastic force to clamp the wire 31. At the same time, the left splint and the swing arm card surface 8 are separated from each other, and the pullback swing arm 3 resistance disappears and can freely rotate upwards.

[0022] (2) When disassembling the grounding wire: pull up the grounding wire 4 or the insulating rope 32, and the wire 31 will move downward relative to the wire clip, and return to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com