Prefabricated external wall

A technology for exterior walls and exterior wall panels, applied in the direction of walls, building components, building insulation materials, etc., can solve the problems of unsuitable interlayer displacement requirements and complex supporting structures, and achieve the effect of eliminating destructive fractures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment is only a preferred technical solution, and the various components and connection relationships involved are not limited to the following implementation described in this embodiment. The configuration and connection relationship of the various components in this preferred solution can be Carry out arbitrary permutations and combinations to form a complete technical solution.

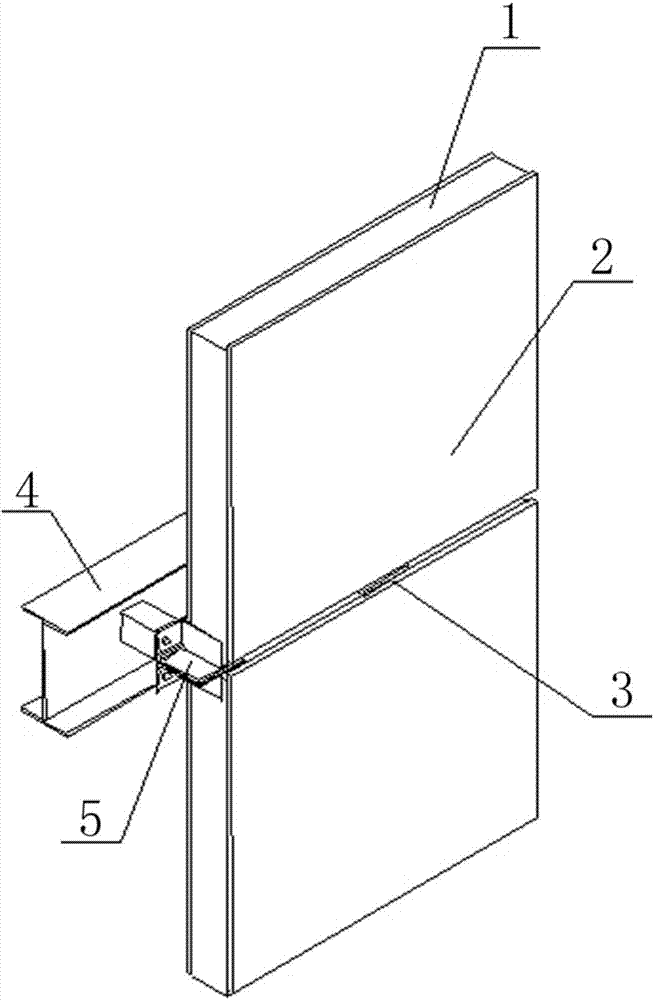

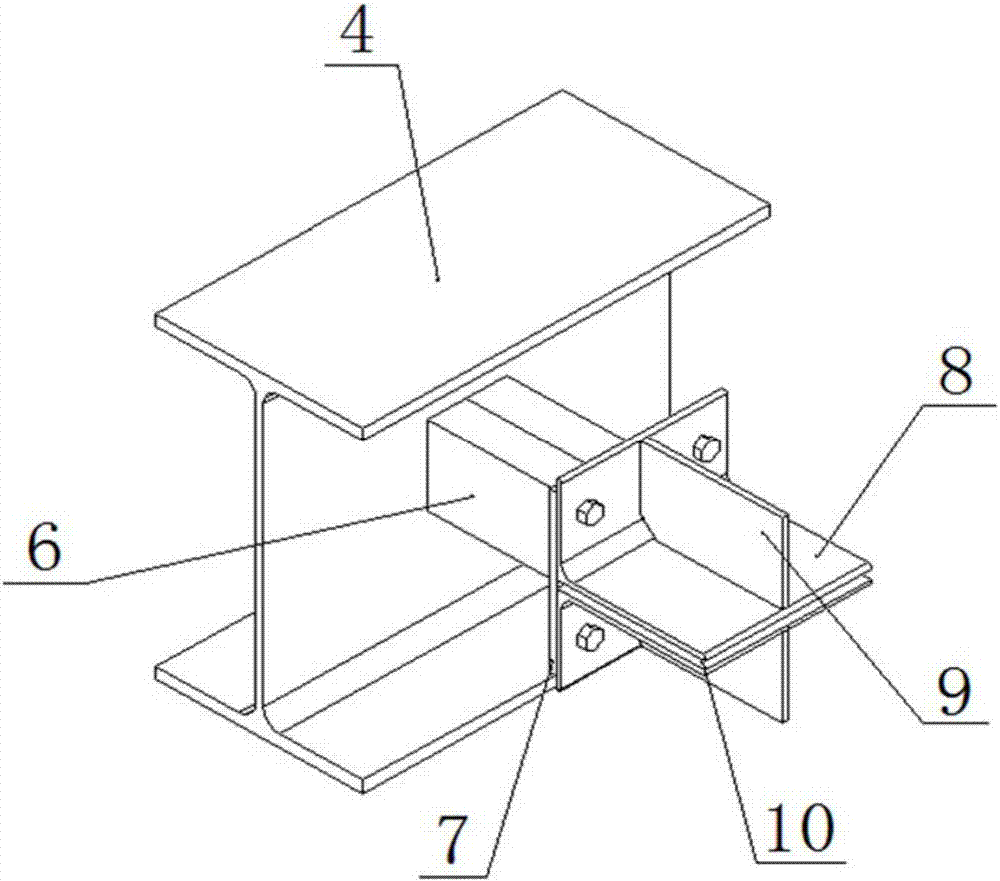

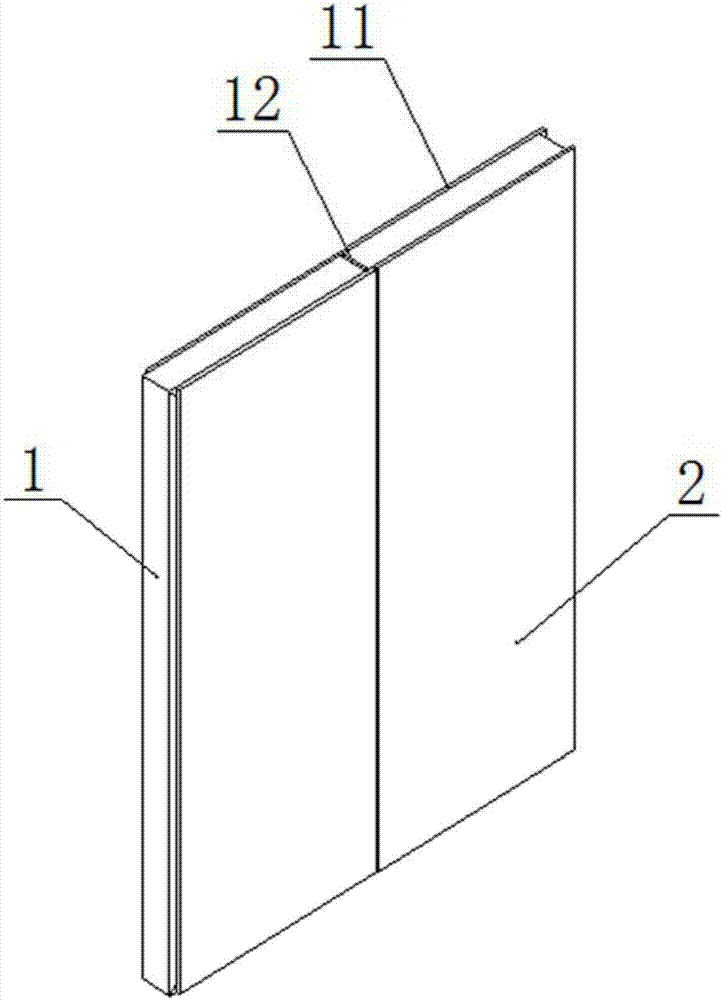

[0029] Combine below Figure 1-3 Describe the technical scheme of the prefabricated exterior wall in detail:

[0030]A prefabricated exterior wall, including a main steel structure 4 and a support 5, the support 5 includes a cantilever member 6, a steel plate connector 7, an L-shaped connector 8, and a stiffening plate 9, and the L-shaped connector 8 includes a vertical plate and a bracket The vertical plate and the supporting plate are vertically and fixedly connected to each other. There are two L-shaped connectors 8, and the two L-shaped connectors 8 are arranged to face up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com