Garment lapel collar ng original number design and cutting method

A garment and lapel technology, which is applied in the field of NG original number design and cutting method of garment lapel collar based on clothing style and comfort, which can solve the problems that the collar piece lining cannot be cut in front of the garment piece, and achieve fast cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

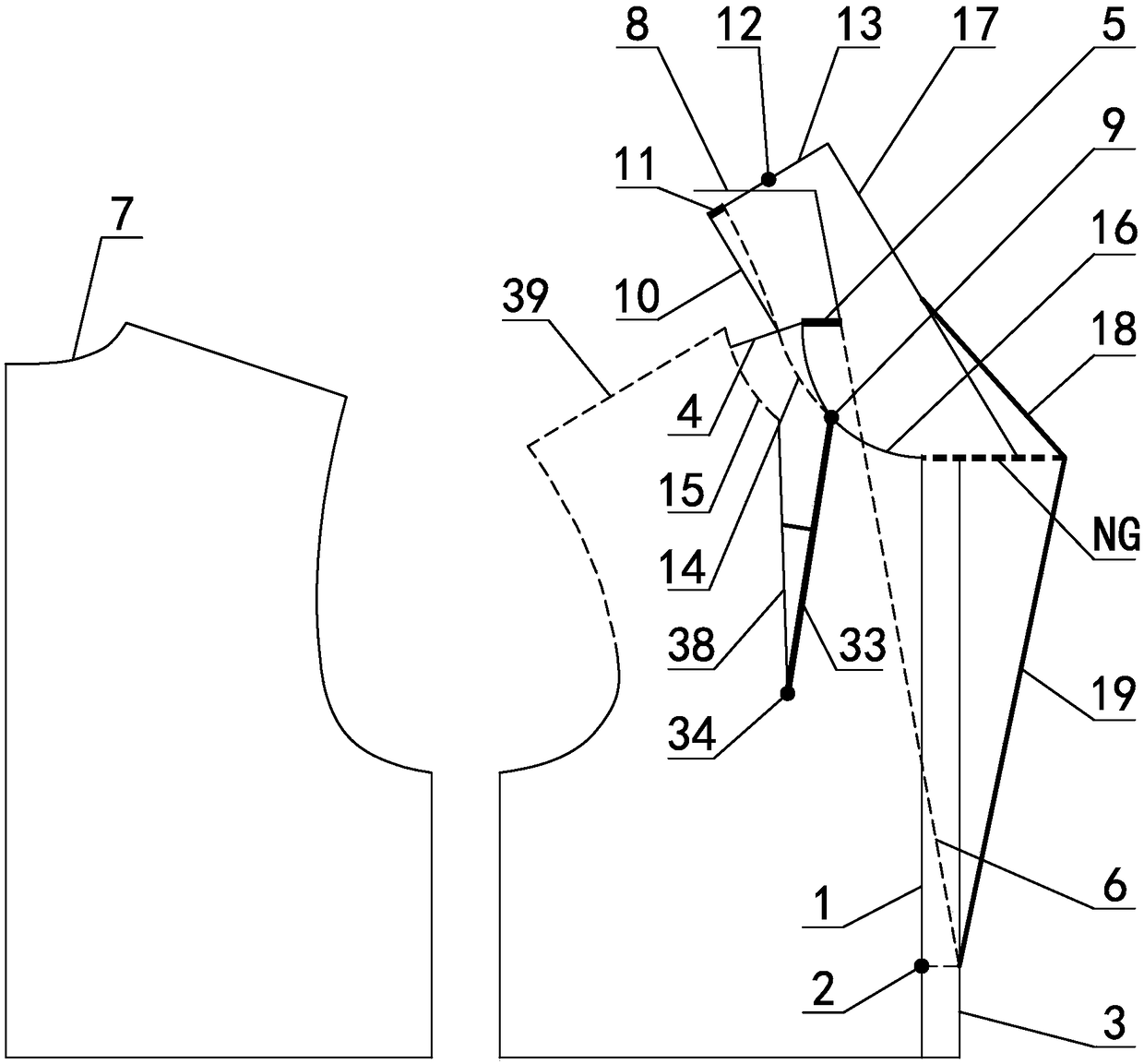

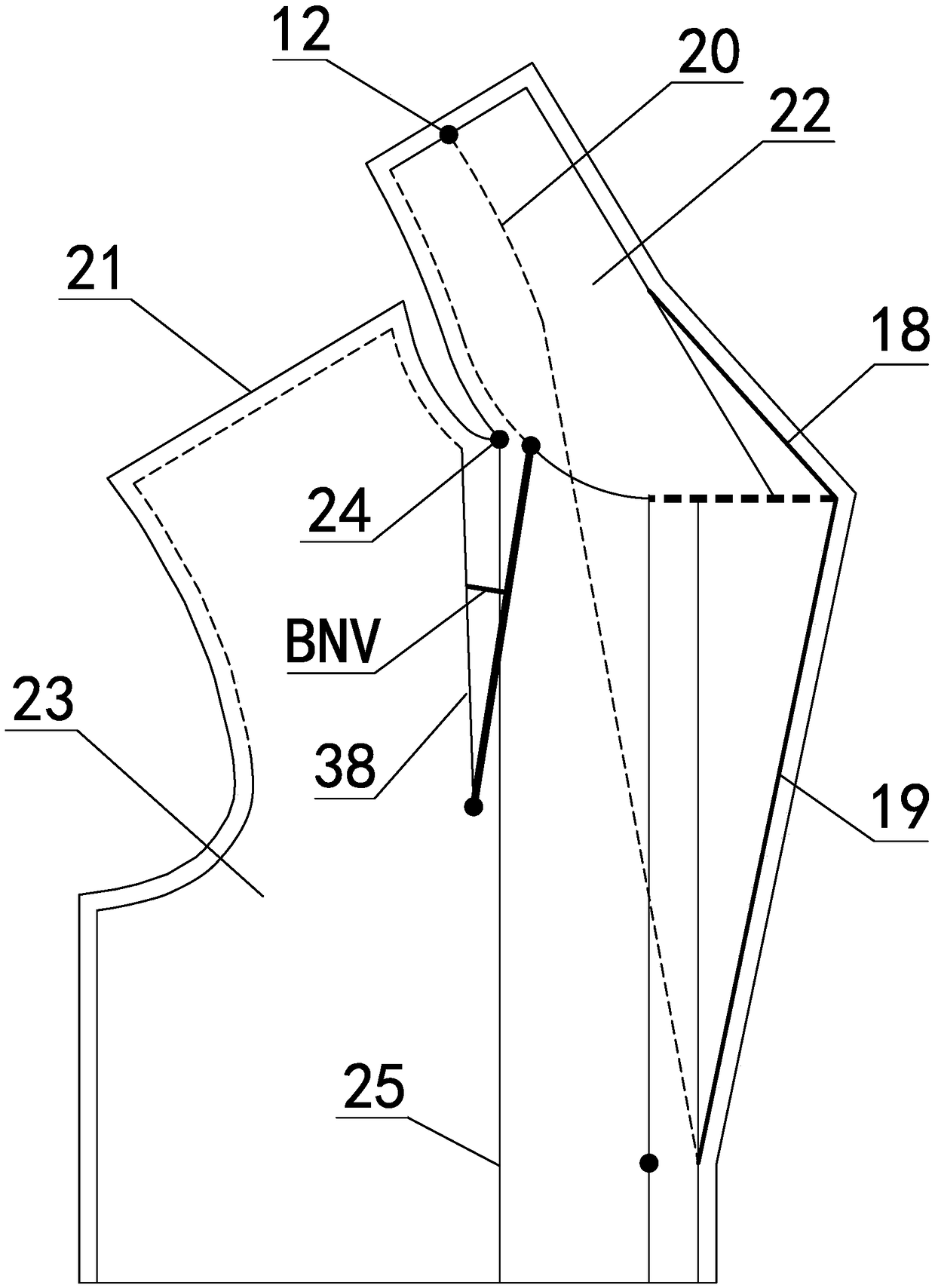

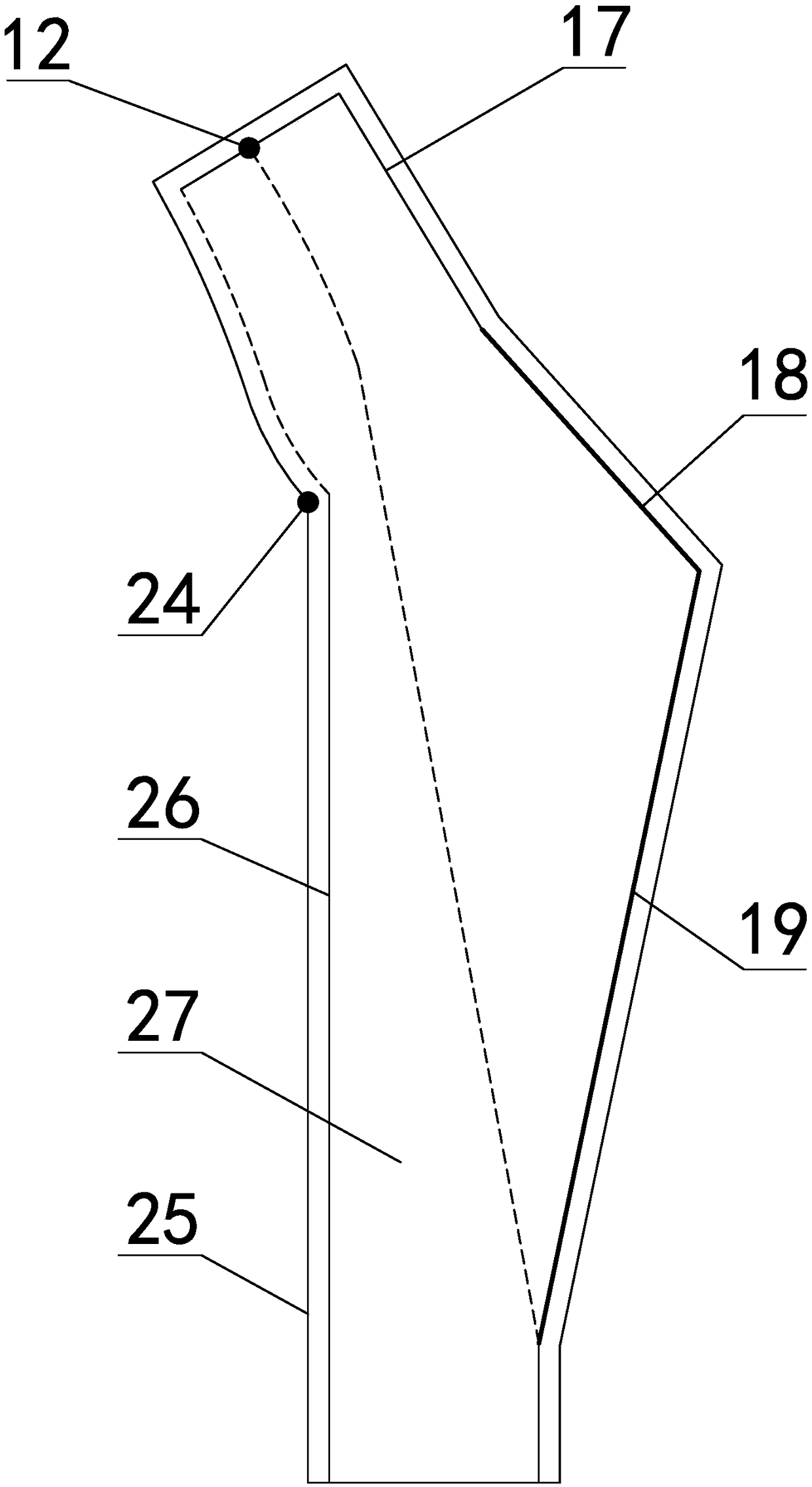

[0030] in such as figure 1 In the shown embodiment 1, a kind of clothing connects collar NG original number design cutting method, comprises the following steps:

[0031] a. According to the clothing style, determine the original number of garment specifications such as upper collar mid-width, lower collar mid-width, and folding door width.

[0032] b. According to the garment collar dart design and cutting method, complete the front and rear garment piece diagrams including collar darts. In the front garment panel diagram, according to the height required by the clothing style, determine the first button point 2 along the middle line 1 of the garment according to the stacking method. For the door width specification, draw a folded door line 3 outside the clothing center line and parallel to the clothing center line.

[0033]c. Based on the right end of the original shoulder line 4, draw the control barge line 5 flatly, the length of the control barge line = the middle width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com